Железный песок низкая цена железный покупатели в

- Категория: Руда >>>

- Поставщик: Gongyi,City,Meiqi,Industry,&,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.88 $* | 0.15 $* |

| Aug-20-2025 | 0.93 $* | 0.17 $* |

| Jul-20-2025 | 0.16 $* | 0.36 $* |

| Jun-20-2025 | 0.13 $* | 0.88 $* |

| May-20-2025 | 0.2 $* | 0.88 $* |

| Apr-20-2025 | 0.38 $* | 0.70 $* |

| Mar-20-2025 | 0.6 $* | 0.0 $* |

| Feb-20-2025 | 0.98 $* | 0.61 $* |

| Jan-20-2025 | 0.94 $* | 0.15 $* |

Характеристики

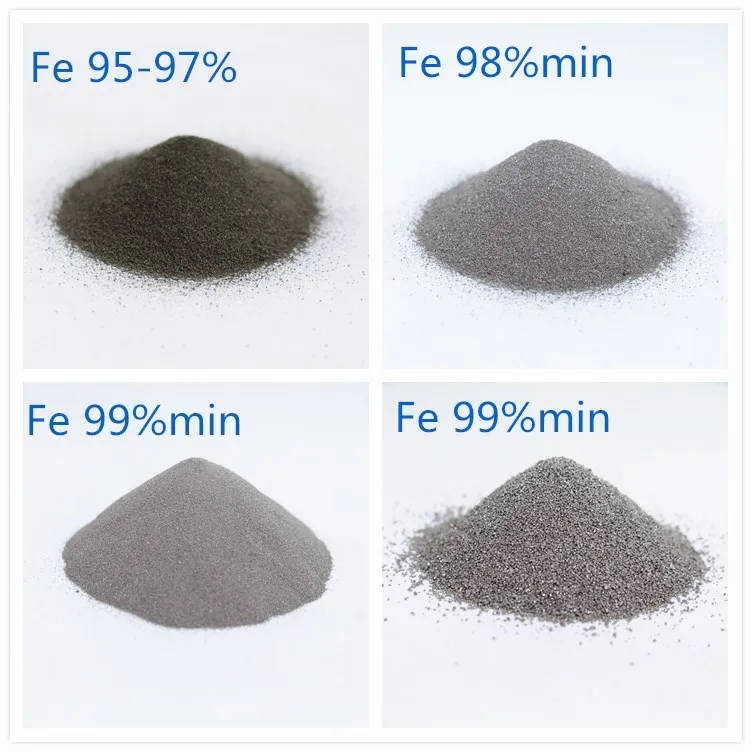

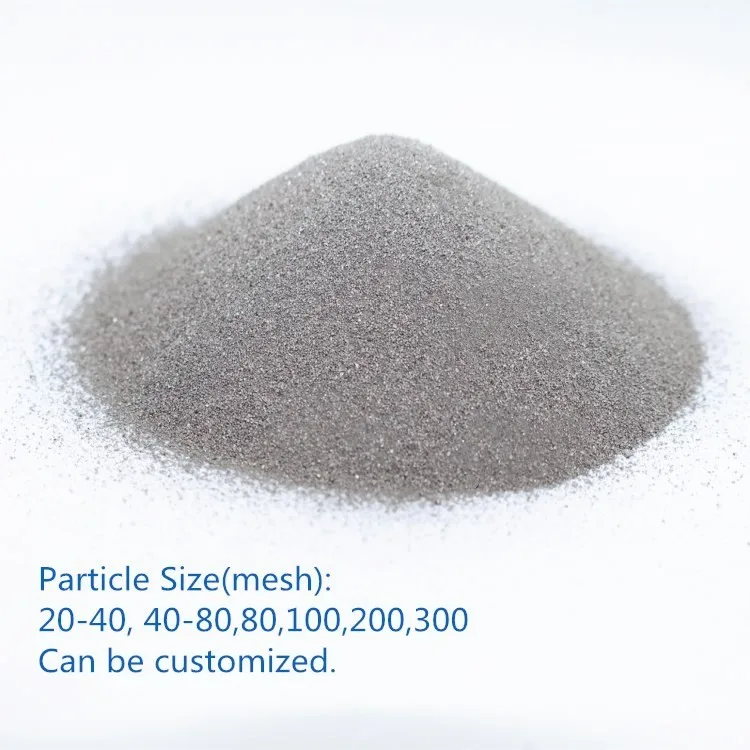

Iron Sand Low Price Iron Sand

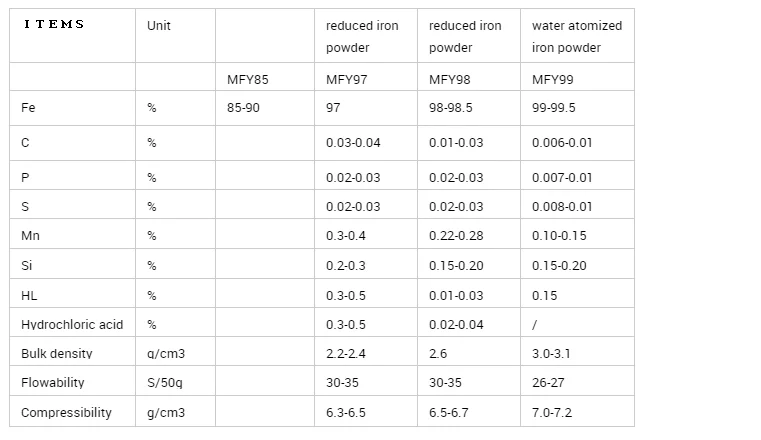

Iron powder used in the production of powder metallurgy iron-based products of iron powder, its quality indicators include: general chemical components, such as iron, carbon, oxygen, sulfur, phosphorus and acid insolubles content, oxygen content available hydrogen loss (loss weight) of the reduction in hydrogen approximately;Physical and technological properties, such as size composition, loose packing density, fluidity, compressibility and sintering dimension stability.

Such as high density, high strength as manufacturing machinery parts, oxygen content of iron powder and compressibility (iron powder was pressed in certain pressure can reach the compact density) indicators have strict requirements.Reductive method and atomization method have been able to produce low oxygen content and high compressibility of high quality iron powder.

ITEMS | Unit | Cutting Easy Iron Powder | Partially AlloyedSteel Iron Powder | Valve Seat Iron Powder | ||||||

MYL10 | MYA12 | MYA15 | MYA16 | MYA18 | MYA20 | |||||

Bulk density | g/m³ | 3.19 | 2.70-3.05 | 3.0±0.1 | 2.90-3.15 | 2.90-3.15 | 3.20-3.40 | |||

Flowability | S/50g | 36 | ≤33 | ≥25 | ≤33 | ≤33 | ≤40 | |||

Compressibility | g/m³ | |||||||||

600MPa | % | 7.08 | ≥7.05 | ≥7.05 | ≥7.05 | ≥6.80 | ||||

500Mpa | % | ≥6.70 | ||||||||

Fe | % | balance | balance | balance | balance | balance | balance | |||

C | % | 0.7 | ≤0.02 | 0.02-0.8 | ≤0.02 | ≤0.02 | 1.7-1.9 | |||

P | % | ≤0.013 | ≤0.02 | ≤0.015 | ≤0.02 | ≤0.02 | ≤0.02 | |||

S | % | 0.3 | 0.20-0.45 | 0.025-1.5 | ≤0.025 | ≤0.025 | ≤0.03 | |||

Mn | % | 0.12 | 0.1-0.45 | 0.15-1.5 | ≤0.15 | ≤0.15 | ≤0.5 | |||

Si | % | 0.027 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.3 | |||

Ni | % | 1.60-1.90 | 3.50-4.20 | ≤0.3 | ||||||

Mo | % | 0.40-0.55 | 0.40-0.55 | 3.00-3.80 | ||||||

Cu | % | 1.8 | 1.40-1.60 | 1.40-1.60 | ||||||

Cr | % | 3.50-4.00 | ||||||||

Co | % | 5-6 | ||||||||

O | % | 0.13 | ≤0.15 | |||||||

particle size distribution | ||||||||||

>180 | 0.1 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | ||||

180-150 | 2 | <10 | <10 | <20 | <20 | <10 | ||||

150-63 | balance | balance | balance | balance | balance | balance | ||||

<63 | 40.7 | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | ||||

Iron powder Application

1.Heat pack;

2.Welding rod making;

3.As Catalyzer for Noble metal reduction, alloy additive, Copper replacement, etc..

4.Stainless steel cutting

5.Making car Brake.

6.Diamond tool production

7.As Sponge iron deoxidizer.

8.Water treament

9.Magnetic mask.

Packing: 25kg/bag , 1000kg/bag or as customers' requirement.

Delivery: Within 15 days after received the advanced payment.

100% factory manufacture and factory direct sales

We have more than 10 years of experience in producing metal powder.

We have ISO9001 quality management system certification.

We have a professional team and technical personnel, can solve all the problems you meet .