Машина для удаления пузырьков мобильных телефонов по заводской

- Категория: Оборудования для электронных изделий >>>

- Поставщик: Zhangjiagang,Genyond,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-15-2025 | 650617.65 $* | 663629.47 $* |

| Jul-15-2025 | 527666.7 $* | 538219.71 $* |

| Jun-15-2025 | 640371.22 $* | 653178.50 $* |

| May-15-2025 | 635248.59 $* | 647953.14 $* |

| Apr-15-2025 | 507174.84 $* | 517317.97 $* |

| Mar-15-2025 | 625002.15 $* | 637502.56 $* |

| Feb-15-2025 | 619879.68 $* | 632277.6 $* |

| Jan-15-2025 | 614756.60 $* | 627051.8 $* |

Характеристики

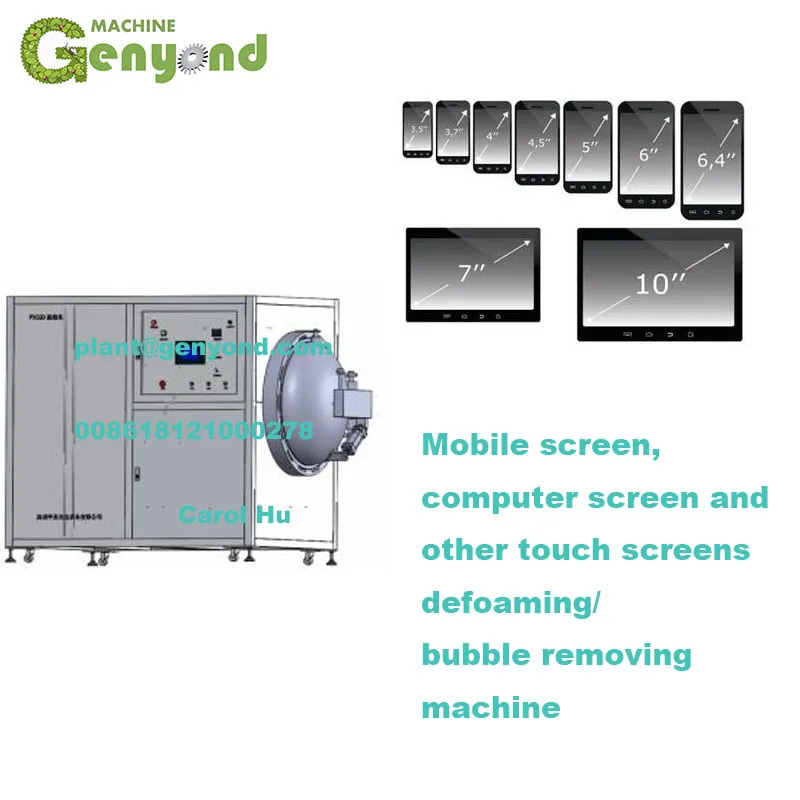

Factory price bubble remover machine for mobile

Product Detail

| Material | Stainless steel or carbon steel |

| Function | Remove bubble generated during bonding process of polarizer |

| Principle | High temperature and high pressure |

| Application | Oca touch LCD screen |

| Degree of automation | Semi-automatic/automatic |

| Internal diameter | 400-1800mm |

| Pressure | 0.7-1.0MPa |

| Temperature | 90 degrees Celsius |

| Product Keywords | bubble remover machine for mobile |

Air bubble remover for lcd repair with new design is designed for LCD and touch screen, By increasing the pressure and temperature in the tank, it can effectively remove the air bubble between the Polaroid and LCD glass, ITO pet film and glass, touch screen polarizing film and protective film. To ensure the quality of LCD,the high pressure air bubble removing machine is a full automatic type, PLC can set working pressure, working temperature and time according to different wafer product, to achieve a perfect bubble removing effect.

The machine is used for strengthening lamination and removing bubbles after flex to rigid lamination, rigid to rigid lamination and other product lamina.

Size (Inner diameter of cylinder*Length)mm | Material | Degree of automation |

| 400*500 | 1.Carbon steel 2.SUS304 Stainless steel | 1.Automatic 2.Semi-automatic |

| 500*600 | ||

| 600*800 | ||

| 800*1200 | ||

| 1000*1200 | ||

| 1200*1350 | ||

| 1300*1680 | ||

| 1500*1800 |

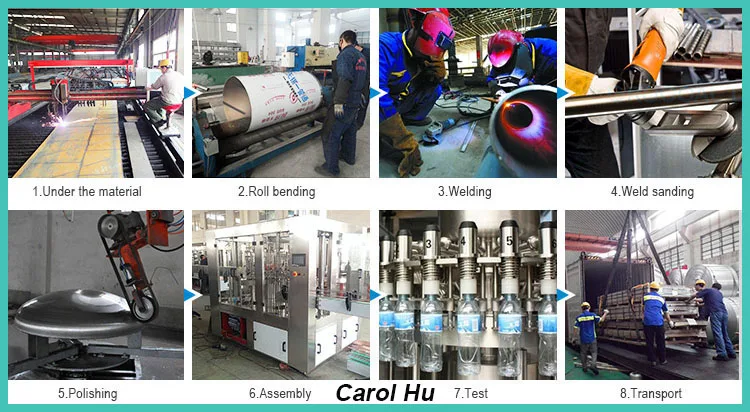

Structure:

Modern techniques

Superior performance

Easy operation

Reliable operation

High pressure defoaming machine adopts advanced manufacturing technology. It is mainly composed of cylinder block, kettle door, pipeline system, control system, decorating parts and so on.

Cylinder block

The cylinder body is designed and manufactured according to the national standard of "GB-150 steel pressure vessel" and the "Pressure Vessel Technology Supervision Regulations", and is made of stainless steel S30408 material.

The cylinder has a standard overpressure relief valve, and the overpressure relief valve ensures the safety of the cylinder block.

Cauldron door

The kettle door adopts the quick open design, by turning the bracelet to realize the opening and closing of the kettle door, sealing the kettle door with the air pressure type sealing strip, and making the operation and maintenance simple.

Pipeline system

It is mainly composed of pneumatic valves, pipes and other auxiliary pipes. Pneumatic valve control wiring is simple, reliable and smooth operation, to avoid electromagnetic valve due to remanent magnetism, magnetic flux generated and can not be opened or closed.

Control system

The color touch screen and the S7-200 series industrial programmable controller of German SIEMENS company are the main controller, which are shockproof, moistureproof and anti electromagnetic interference, and the performance is stable and the operation is reliable. The advanced control software is used for digitalization of the defoaming temperature, so that the defoaming time is scientific and reasonable, and the defoaming effect is ensured reliably. The input color touch screen can display the temperature, pressure and time intuitively in the course of operation. It can input the name, batch number, operator and so on according to the customer's request. The whole travel parameter data is stored in the touch screen with memory, and the data can be exported with the U disk, and the micro printer can also be printed out.

The defoaming is complete. The high pressure defoaming machine produced by our company is using hot air circulation and high pressure air, which can effectively prevent the production of inner chamber cold air mass and ensure the effect of defoaming. In addition, the air in the inner chamber is in an uninterrupted circulation state, the heat gas penetrability is strong after heating up, and there is no dead angle between the materials, and energy saving can be saved in a large amount.

The operation is simple and the degree of automation is high. All the control systems are controlled by a computer touch screen. As long as the switch is turned on, automatic control is achieved in all aspects of intake, exhaust, heating, and pressure keeping.

It is advanced in technology and flexible in setting. According to the defoaming requirements of different products and the technical parameters such as defoaming temperature and time, the free setting or fixing procedure can be adopted to achieve the defoaming effect and a multi - use machine. Please refer to the instructions for the use of the equipment below.

High quality, low price, low maintenance rate. The main accessories of the products are imported parts, for example, the control system is SIEMENS, and the pneumatic valve is the elite of Qingdao. Because the main accessories selected by our company are basically imported parts, the maintenance rate is very low. Although the configuration of the product is high, the price of the product is lower than that of the same industry.

The design is reasonable and the specifications are complete. The defoaming machine produced by our company has all sizes from 400mm to 1800mm. The size and volume requirements of the inner chamber of the defoaming machine are mainly based on the user's output requirements, and users can design free information about the defoaming machine free of charge.

Excellent pre sales and after-sales service system.

Похожие товары

Индуктивная обмоточная машина CD, Индуктивная обмоточная машина NR

High quality wireless Electric ST16MM Feeder for

NXT TB0038 24mm Electric Feeder for SMT fuji feeder

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com