Керамический подшипник устойчивые к высоким температурам и коррозионные керамические роликовые подшипники из оксида алюминия

- Категория: Керамические шарикоподшипники >>>

- Поставщик: Dongguan,Mingrui,Ceramic,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.6 $* | 0.21 $* |

| Aug-20-2025 | 0.47 $* | 0.12 $* |

| Jul-20-2025 | 0.37 $* | 0.37 $* |

| Jun-20-2025 | 0.57 $* | 0.54 $* |

| May-20-2025 | 0.95 $* | 0.47 $* |

| Apr-20-2025 | 0.95 $* | 0.60 $* |

| Mar-20-2025 | 0.23 $* | 0.35 $* |

| Feb-20-2025 | 0.74 $* | 0.97 $* |

| Jan-20-2025 | 0.28 $* | 0.50 $* |

Характеристики

About product price

1. We are a manufacturer of ceramic parts products for many years, the product price discount, ceramic engineer services.

2. Component factors of product price: product quantity, product materials, product processing steps, product precision, product structure complexity, shipping mode, receiving place, exchange rate and other factors.

3. The more detailed the information you provide, the sooner we can quote and the lower the price.

4. We offer the service of making samples, some of which are free of charge.

5. We provide free quotation consultation and relevant information of ceramic parts.

In this page, if you do not find the industry, equipment, practical application, familiar with the use of ceramic products you looking for , please contact us in time, we are ceramic engineer services, professional ceramic parts services, rich manufacturing knowledge.I hope I can help you in time.thank you

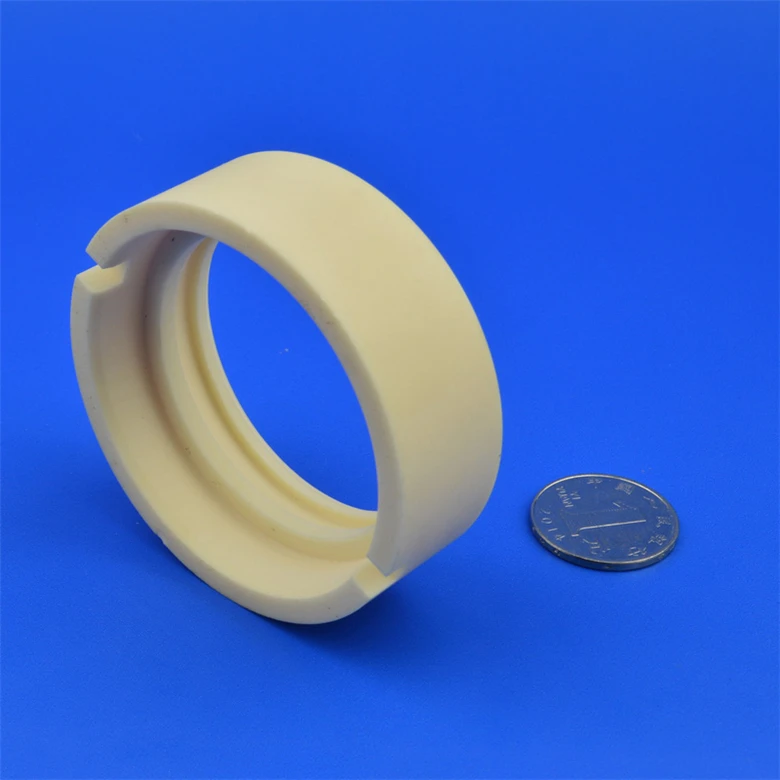

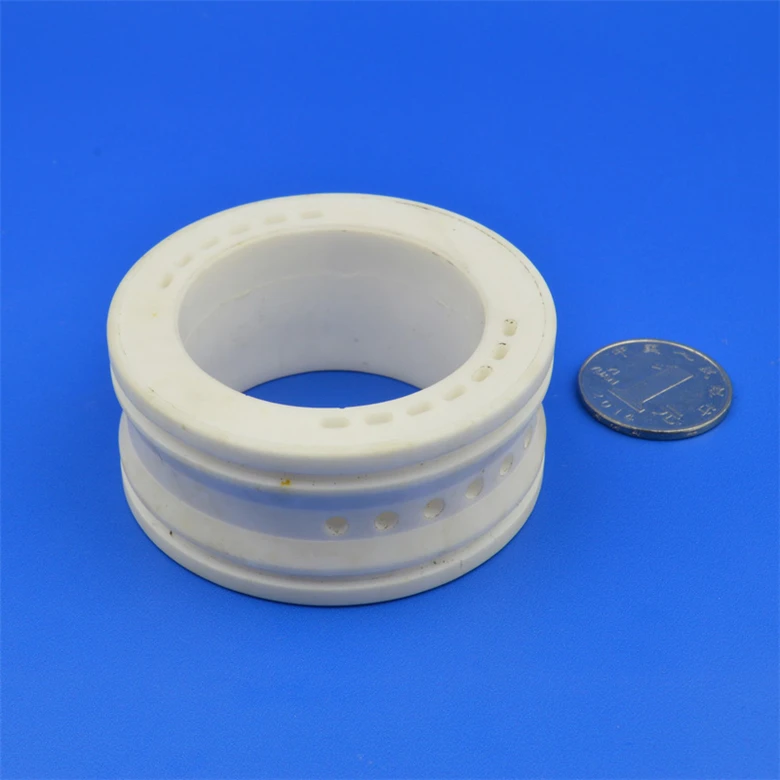

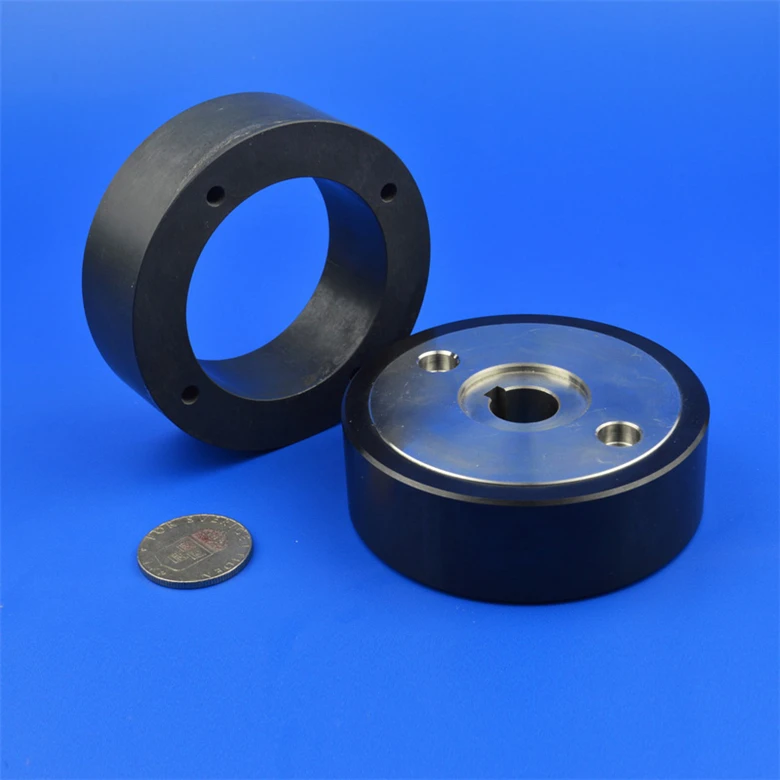

Ceramic Bearing Anti - High Temperatures And Corrosive Alumina Zirconia Ceramic Roller Bearings

Full Ceramic Bearings have races and balls that are made entirely of ceramic material and are superior to common steel bearings in many ways. Ceramic is the perfect material for any application seeking to achieve higher RPM’s, reduce overall weight or for extremely harsh environments where high temperatures and corrosive substances are present.

Full Ceramic Bearings are usually made of following materials:

· Silicon Nitride (SiN4)

· Alumina Oxide (Al2O3)

· Zirconia Oxide (ZrO2)

· Silicon Carbide (SiC)

Because ceramic is a glass like surface it has an extremely low coefficient of friction and is ideal for applications seeking to reduce friction.

Full Ceramic Bearing Benefits

· Will not corrode or rust

· 2/3 the weight of steel

· Resistant to resist acids, alkali, blood, salt and water

· Extremely low coefficient of friction and thermal expansion

· Lower friction results in less energy consumed

· Operating Temperature from as low as (-85°C) up to (+ 1750°C)

Full Ceramic Bearing Applications:

Full Ceramic bearings are used in specialty applications like chemical baths, vacuum environments, semiconductor manufacturing, food processing industries and more. Any extreme environment that requires non-corrosive, non-conductive or non-magnetic bearings is ideal for full ceramic bearings.

Ceramic material composition:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

...

The properties of ceramic:

·Excellent physical & chemical stability ·High temperature resistance

·Excellent wear & pressure & corrosion& insulation resistance and thermal conductivity...

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm3 | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Thermal shock resistance | T(℃) | 180-220 | 280-350 | 230-260 | / |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Tensile strength | MPa | 248 | 250 | / | / |

Manufacturing parameters:

| Additional Information:

| |||||||||||||||||||||||||||||

As a manufacturer of ceramic parts, we offer customization of ceramic for special sizes and shapes.High Precision, Fast Delivery Time, High Composition.

CULTURE

We are a leading manufacturer of industrial ceramic parts, who has years of R&D experience in China. And very advanced technologies in the production of zirconia and alumina ceramic tube, ceramic rod, ceramic plate, ceramic ring, ceramic sleeve, ceramic valve, ceramic piston plunger pump, and semiconductor ceramics, etc.

They are applicable to Electrical, Appliance, Mining, Oil & Gas, Energy & Power, Food & Medical, Agriculture, Aerospace, even other high-end fields.

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., the 2nd Industrial Zone of

Shangsha,Chang'an town, Dongguan city, Guangdong,China

Tel: +86 0769 85090316

Fax: +86 0769 85090326

Skype: +86 18122972636

Mobile: +86 18122972636

Official website: http://www.cerampart.com/

Tina Wu

Email: admin @cerampart.com

Skype: +86 181 2297 2636

Mobile: +86 181 2297 2636 Wechat: 008618122972636 WhatsApp: +86 18122972636

Add: Dongguan city, Guangdong, China