Дверная пластина тиснение горячий пресс машина/дверной холодный для

- Категория: >>>

- Поставщик: Shanghai,Chanho,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.16 $* | 0.96 $* |

| Aug-17-2025 | 0.71 $* | 0.68 $* |

| Jul-17-2025 | 0.6 $* | 0.40 $* |

| Jun-17-2025 | 0.7 $* | 0.50 $* |

| May-17-2025 | 0.65 $* | 0.55 $* |

| Apr-17-2025 | 0.40 $* | 0.72 $* |

| Mar-17-2025 | 0.53 $* | 0.64 $* |

| Feb-17-2025 | 0.96 $* | 0.9 $* |

| Jan-17-2025 | 0.41 $* | 0.11 $* |

Характеристики

Door plate embossing hot press machine/door skin cold press for mould door

Specification for door skin production machine

The 900-1400T multi-layer hot press for door skin has several work layers, and it requires door moulds. It functions like a molding press, but it actually makes use of hot platens to form the shape of door skins and add laminates on the door skins. This product is commonly used to bond veneer or melamine layer to the door skins surface in the manufacturing process of moulded door skins.

Advantages

The most important thing for a multi-layer press is the simultaneous-closure device. This device is designed to maintain uniform spacing between these platens during the closure of the press, making all the products under the same temperature and pressure. So, it will be much easier to control the product quality.On the other hand, our hot press is also equipped with a guiding mechanism to guarantee precise positioning of the platens during closure. The aforementioned simultaneous-closure device is responsible for the uniformity of platens in the vertical direction, while this guiding mechanism ensures good uniformity in the front-back and left-right directions. In this way, the upper and lower door moulds could match with each other perfectly, thereby outputting high quality door skins.

Technical Parameters | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Recommended Process Parameters |

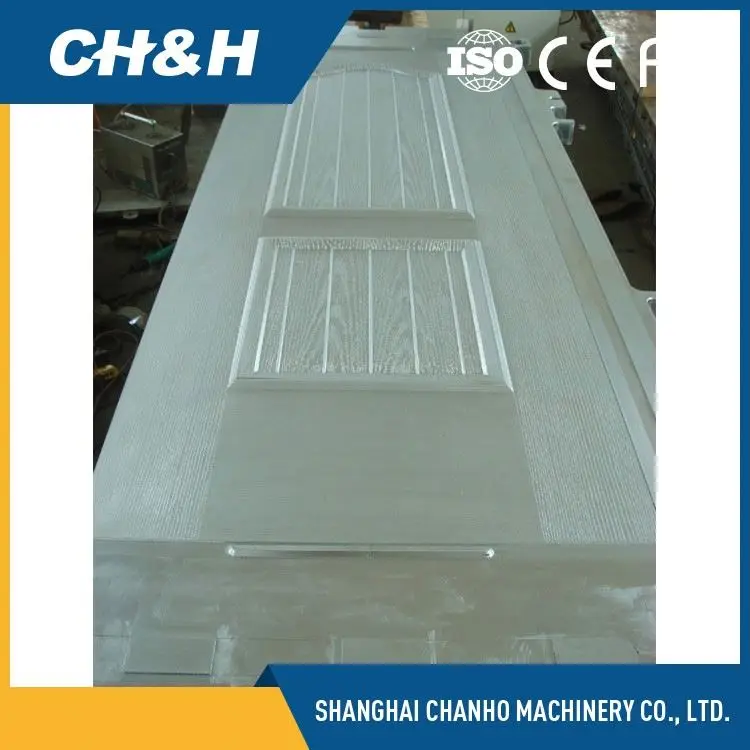

Pictures for door skin production machine