Ordinary AAC Blocks (whatsApp Riva

- Категория: >>>

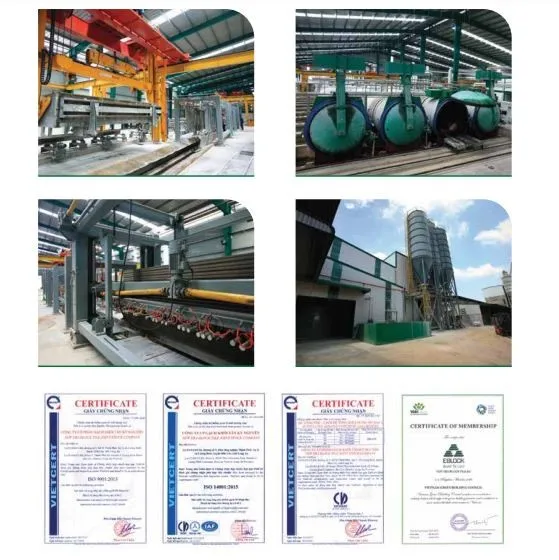

- Поставщик: NEW,ERA,BLOCK,TILE,JOINT,STOCK,COMPANY

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 5379.1 $* | 5648.91 $* |

| Aug-16-2025 | 5334.71 $* | 5601.1 $* |

| Jul-16-2025 | 4475.8 $* | 4699.51 $* |

| Jun-16-2025 | 5243.29 $* | 5505.74 $* |

| May-16-2025 | 4565.8 $* | 4793.93 $* |

| Apr-16-2025 | 5153.11 $* | 5411.54 $* |

| Mar-16-2025 | 5108.51 $* | 5363.51 $* |

| Feb-16-2025 | 5062.6 $* | 5315.16 $* |

| Jan-16-2025 | 5017.37 $* | 5268.4 $* |

Характеристики

What is AAC Block?

Autoclaved Aerated Concrete or AAC is a lightweight, precast concrete material that comes in two forms: blocks and panels. It was developed in Sweden during the 1920s. AAC offers structural strength, heat and sound insulation, and fire resistance in one material.

Being aerated, AAC contains 50-60% air and has a density of 750 kgs/cbm. Although it weighs only about 40% of conventional CHB, the compressive strength averages 4.25 MPa which is twice the PNS (Philippine National Standard) requirement for Type II non load-bearing CHB.

Unlike other concrete products, AAC may be sawn, drilled, chiseled, nailed or screwed using conventional carpentry or electric power tools. Thin bed mortar is used as adhesive to join the blocks or panels together.

Its main ingredients (cement, lime, silica sand, gypsum, and water) are mixed into a slurry. Aluminum powder is added as an expansion agent. The chemical reaction generates tiny air bubbles and causes the mixture to expand to nearly twice its original volume.

After its initial setting, it transforms into a semi-solid state which is then wire cut into precisely sized blocks or panels and then baked (autoclaved).

Autoclaving uses high-pressure steam at temperatures of up to 190°C to accelerate hydration of the concrete. It can produce in 8 to 14 hours concrete strengths equal to that of concrete moist-cured for 28 days at 70°F.