Высококачественная машина для переработки шин и резины оборудование производства резинового сырья измельчитель резиновых

- Категория: Измельчители >>>

- Поставщик: Henan,Like,Recycling,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 59500.56 $* | 62475.67 $* |

| Aug-16-2025 | 59000.72 $* | 61950.58 $* |

| Jul-16-2025 | 49500.64 $* | 51975.75 $* |

| Jun-16-2025 | 58000.16 $* | 60900.25 $* |

| May-16-2025 | 50500.88 $* | 53025.91 $* |

| Apr-16-2025 | 57000.67 $* | 59850.75 $* |

| Mar-16-2025 | 56500.9 $* | 59325.33 $* |

| Feb-16-2025 | 56000.62 $* | 58800.75 $* |

| Jan-16-2025 | 55500.67 $* | 58275.36 $* |

Характеристики

High quality tyre rubber powder process machinery tyre powder plant

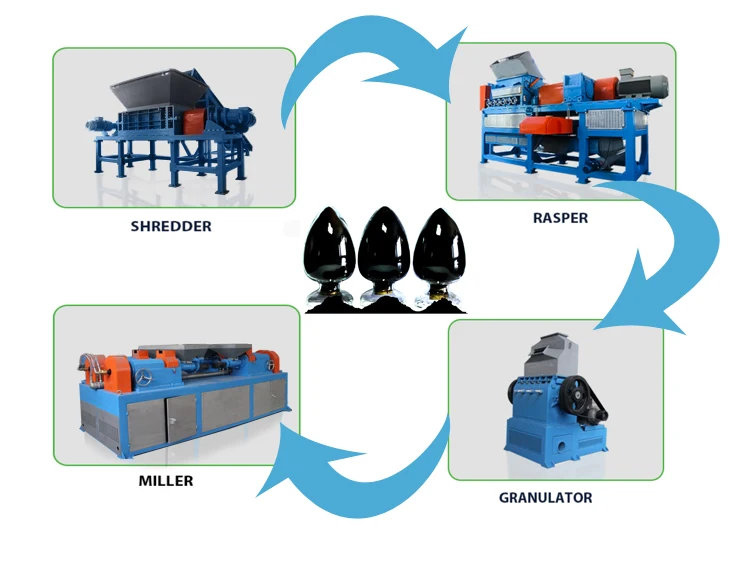

LIKE waste tire recycling production line made of different type heavy equipment,it can realize separate car tire,truck tire and engineering tire fully automatically.Based on client demand,make rubber material pelleting and grinding,this series tire recycling production line working under normal temperature,no need any chemical additive,won't cause secondary environment pollution.recycling within the range of tires 400-3000 mm diameter, strong applicability, the size of the output material can be controlled in the range of 5-100 mm, production can reach 200-10000 kg/h. Choosing the suitable model machine,we make the proposal closed to real production demand,let user control cost and get ultimate pay back by waste tire recycling machine.The whole tire recycling production line can effectively realize the automatic separation of rubber, steel wire, nylon fiber and other materials, the whole line adopts PLC control system, it is easy to operate and maintain, and has the characteristics of low energy consumption and long service life.

The LIKE two-shaft tire crusher is specially designed for old tires with low speed and high torque to minimize noise and power consumption.The blade of the shredder is made of high quality steel and subjected to Bodycote heat treatment to achieve the best crushing performance.The thickness range of the crushing blade is 25mm-152mm according to the tire type,output and final product. The grinder can process OTR tires,big truck tires,car tires and so on at the speed of 1-30tons whithin 1 hour.

Model | Input size | Output size | Cappacity | Motor | Blades quantity | Dimensions | Weight |

TS-800 | 800mm | 50*50mm | 1-2T/h | 2*22kw | 16pcs | 4*2.6*3.2m | 8T |

TS-1200 | 1200mm | 60*60mm | 3-5T/h | 2*37kw | 20pcs | 4.8*2.8*3.5m | 14T |

TS-1600 | 1600mm | 50-150mm | 6-8T/h | 2*45kw | 16-30pcs | 5*2*3.4m | 18T |

TS-1800 | 1800mm | 50-150mm | 7-10T/h | 2*55kw | 20-24pcs | 5.6*2*3.4m | 23T |

TS-2000 | 2000mm | 75-200mm | 10-15T/h | 2*75kw | 20-30pcs | 6*2.4*4m | 36T |

TS-2400 | 2400mm | 100-200mm | 20-30T/h | 2*110kw | 16-24pcs | 7.4*3.2*5.2m | 56T |

LIKE tire shredding system is designed to produce up to 6 tons per hour of wire free rubber mulch.This system produces up to a 99% wire free chip ranging in size between 12-25mm depending on the desired size.After processing,the steel is removed by our magnetic separation system.At this point,the wire free rubber chips are ready to be colored and used for landscaping mulch and the steel is ready to be baled and sold to smelters.

Rasper | Motor | Power | Capacity | Dimensions | Weight | Cutting chamber | Final product |

LK-R45 | Siemens | 45KW | 300-500kg/H | 1.4*1.2*2.3m | 1700kg | 450*600mm | 10-30mm |

LK-R55 | Siemens | 55KW | 500-700kg/H | 1.7*1.7*2.3m | 1850kg | 450*800mm | 10-30mm |

LK-R75 | Siemens | 75KW | 700-1T/H | 2*2*4.1m | 3500kg | 550*800mm | 10-30mm |

LK-R90 | Siemens | 90KW | 1-1.5T/H | 2.1*2.1*4.1m | 4200kg | 550*1000mm | 10-30mm |

LK-R132 | Siemens | 132KW | 1.5-3T/H | 2*2.5*4.1m | 6100kg | 742*1200mm | 10-30mm |

LK-R315 | Siemens | 315KW | 3-6T/H | 6.2*2.1*3.6m | 12400kg | 697*1562mm | 10-30mm |

Tire recycling system for 1-8mm rubber granules:

Input: waste tires ( car, passenger car and truck tires)

The tires should be free of flammable fluids as well as foreign bodies such as stones etc. Dimensions of the tyres are to be maximum diameter of 1200mm.

De-beading of the OTR tires is not required to processing in LIKE shredder.

Rubber powder is the final result of ambient tire recycling.At this stage,crumb rubber is ground down into a clean powder form with virtually all steel and fiber removed.Rubber powder has numerous secondary uses from injection molding products,coatings,roofing materials and various asphaltapplications.

Rubber powder is typically found in 40-74 microns(0.40-0.74mm) in size.This micron size metarial has the advantage of being incorporated into new or existing formulations for various polymers and finished products.

Rubber powder | M2000 | M1500 | M1000 | M500 | |||

Input product | Heavy duty truck tyres to bicycle tyres | ||||||

Input size | Diameter 1800mm | Diameter 1800mm | Diameter 1800mm | ||||

Output size | shred to 30-120 mesh rubber powder | ||||||

Capacity | 1500kg/h | 1000kg/h | 500kg/h | ||||

Total Kw | 680-760kw | 516-556kw | 347-372kw | 170-190kw | |||