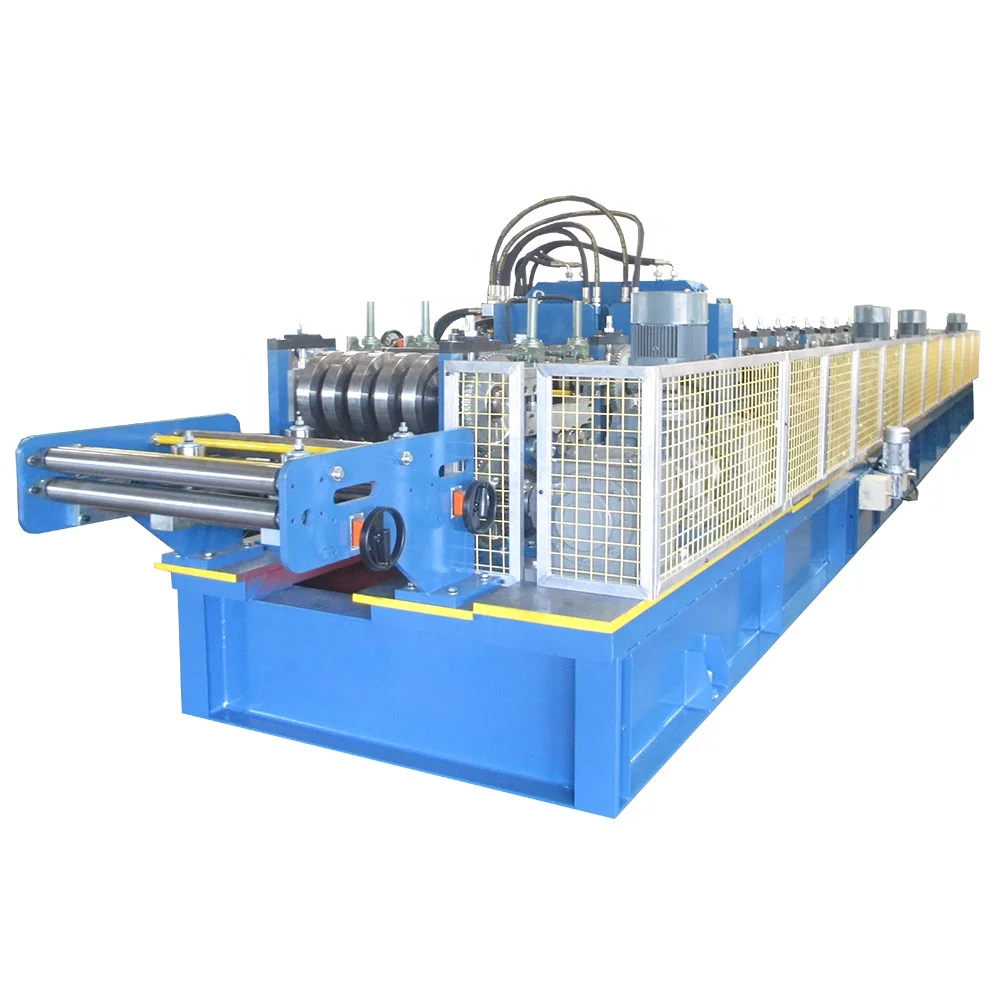

Машина для профилирования сменных рулонов CZ машина прокатки каналов C Z высококачественное оборудование

- Категория: Steel Frame & Purlin Machines >>>

- Поставщик: Hangzhou,Zhongyuan,Machinery,Factory

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 80920.49 $* | 84966.46 $* |

| Aug-18-2025 | 80240.34 $* | 84252.83 $* |

| Jul-18-2025 | 67320.99 $* | 70686.61 $* |

| Jun-18-2025 | 78880.62 $* | 82824.82 $* |

| May-18-2025 | 68680.46 $* | 72114.73 $* |

| Apr-18-2025 | 77520.55 $* | 81396.39 $* |

| Mar-18-2025 | 76840.11 $* | 80682.60 $* |

| Feb-18-2025 | 76160.21 $* | 79968.9 $* |

| Jan-18-2025 | 75480.21 $* | 79254.15 $* |

Характеристики

CZ Purlin Interchangeable Roll Forming Machine,C Z Channel Rolling Machine High Quality Machinery Automatic CZ Purlin

Why choose this machine?

1. Certificate: ISO 9001, CE,

2. Lifetime services

3. Roller cover with 0.05mm chrome; 82mm diameter solid steel shaft. Lifetime>10years.

4. Introduced Mitsubishi PLC with touch screen to machine controll system.

5. One worker operation (minimum)

6. Heat treatment:Cutting blade. Quenched treatment: Cr12 mould steel cutter

7. Product cut-to-length.

8.Technician overseas installing and training available

CZ Purlin Roll Forming Machine Feature:

The C shaped purlines formed by C shape roll forming machine have excellent anti-bending property and are easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

1. CZ Purlin Roll Forming Machine Technical Parameter:

Item | Specification | |

Material | Type | Galvanized coils |

Thickness | 1.5-3.5mm | |

Yield strength | 235Mpa | |

Roller material | Cr12 mould steel | |

Forming speed | 10-15m/min | |

Output speed | 6-8m/min | |

Speed adjusting mode | AC Frequency | |

Roller drive | Decelerating motor + Gear boxes drive | |

Cutting mode | Hydraulic cutting | |

Cutter material | Cr12 mould steel | |

Length measurement | Encoder | |

Control mode | Mitsubishi PLC | |

Operating mode | Button + Mitsubishi Touch screen | |

Main motor | 15KW | |

Hydraulic Station motor | 5.5KW | |

2. CZ Purlin Roll Forming Machine Components:

Decoiler | 1set |

Feeding & guiding device | 1set |

Leveling device | 1 set |

Punching device | Depend on final design |

Main roll forming machine | 1set |

Hydraulic cutting system | 1set |

Controlling system | 1set |

Run out table | 1set |

3. CZ Purlin Roll Forming Machine Process flow:

Decoiler ---- Feeding & Guiding----Leveling----Punching----Cutting to length----Roll forming----product to run out table

(Please refer the attached layout drawing of production line):

PACKAGE:

1. need about 1*40gp container for loading one set machine completely;

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

DELIVERY TIME:

within 90 days after getting advance payment.