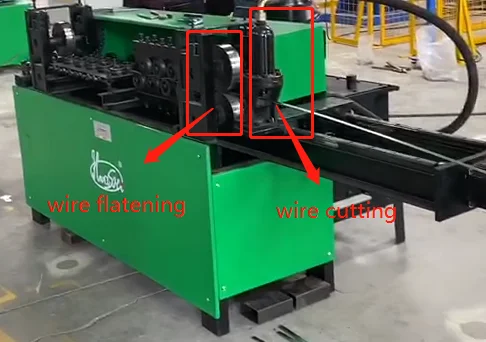

HWASHI 12x10 мм машина для сплющения проволоки и резки плоской проволочной

- Категория: Металлургическое оборудование >>>

- Поставщик: Guangdong,Hwashi,Technology,Inc.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 17850.87 $* | 18743.91 $* |

| Aug-17-2025 | 17700.33 $* | 18585.80 $* |

| Jul-17-2025 | 14850.17 $* | 15593.90 $* |

| Jun-17-2025 | 17400.56 $* | 18270.70 $* |

| May-17-2025 | 15150.80 $* | 15908.38 $* |

| Apr-17-2025 | 17100.18 $* | 17955.98 $* |

| Mar-17-2025 | 16950.2 $* | 17798.39 $* |

| Feb-17-2025 | 16800.74 $* | 17640.25 $* |

| Jan-17-2025 | 16650.91 $* | 17483.42 $* |

Характеристики

1. Wire Flattening Machine

1) Design Purpose and Processing Product:

The material is low carbon steel (hardness is no more than HRC43). The round wire is flattened through cold rolled into flat wire. This machine is designed to do maximum 8mm round low carbon steel wire. The rolling extension rate of each roller is 10% to 25%. The flat wire thickness range is from 2.5mm to 5mm, width is no more than 10mm. After flattening, the wire surface should be smooth. And after electroplated, cannot see the flattening mark. The thickness tolerance is within ±0.1mm. The width tolerance is within ±0.2mm.

2. Wire flattening machine structure:

①Pressing Structure:

i﹜ The wire flattening machine is composed of 1 group of roller. The roller will be made to flatten the suitable round wire to required flat wire. The rolling extension rate of each roller is 10% to 25%.

ii﹜ The roller diameter is 260mm. Thickness is 80mm. Ensure the minimum radial run-out so as to achieve the thickness tolerance within ±0.1mm.

iii﹜ The roller material is Cr12MoV. The surface nitriding after heat treatment and quenching. Ensure the hardness, strength and abrasive resistance is up to the standard. The roller surface hardness is HRC56-61.

iv﹜ The double row cylindrical rolling bearing of the rolling roller shaft is mounted on the mounting plate. The lower roller is fixed on the bearing. The upper roller is mounted on the sliding block and can be adjusted up and down through ball screw so as to adjust the gap between upper and lower roller. It will decide the thickness of the flat wire.

v﹜ The roller installing shaft is made of #45 steel. It has been processed by tempering and heat treatment

vi﹜ Precision vernier caliper is installed at the upper slider of the mounting plate. The gap between roll surfaces is determined by adjusting the reading of the screw according to the requirement of processing flat wire.

②The power and drive mechanism of the wire flattening machine:

i﹜ The rollers are working through motor driven reduction gears.

ii﹜ Motor speed control with frequency conversion governor. The controller center processes the information and controls the roll frequency conversion governor.

Make the front rolling speed and the straight cut feed speed balance.

③ Flat wire cutting device: The wire after flattening will be straightened and cut into required length and dropped into collecting feeder by oil cylinder which is driven by synchronous device.

⑤Cooling device: Each roller pressing station is equipped with strong water cooling device. The water cooling device is composed of self circulating pump.

3,Processing Capability and Working Efficiency

According to different round wire material and processing dimension, the round wire should be low carbon steel round wire within 8mm diameter. The processing speed is around 8m-12m/min. (the speed will be different according to different flattening width, material ductility.

Processing Material:

The straightening wheel is vertical to each other. Totally there are four sets of straightening wheel to ensure the straightening speed and straightness. The straightening wheels are equipped with pressure adjusting structure to ensure the uniform pressure.

2. Cutting device

1) Hydraulic cutting: oil cylinder diameter: 80mm, stroke: 50mm, adjustable stroke.

2) Hydraulic motor power: 2.2KW, 380V

3) Cutting Mould: 2 sets; mould material: SKD-11. Heat treatment hardness HRC60-62.

4) Non-stop cutting (the cutting device is installed at the horizontal slide rail and moved by pushing of forming flat wire.

3. Forming material collecting device: the flat wire after cutting will be delivered to the collecting feeder.

4. Technical data:

1) low carbon steel round wire maximum diameter: 8mm. One time extension rate: 10-25%;

2) no scratch during straightening process. 3) Output rate: 30m/min.

Controller:

1. In order to form the wire with different material, the rollers speed is adjustable. And the speed adjusting controller is installed to adjust the speed for different product.

2. Cutting the wire with required length is controlled by PLC with high precision and quick speed.

3. Equipped with counter to count the output automatically. Prevent waste for over output.

Story About HWASHI

Guangdong Hwashi Technology Inc. was established in 2001. The headquarter is located in Hwashi industrial park in Huizhou. Hwashi is a high-tech enterprise specialized in developing, manufacturing and selling of resistance welding machine, automatic welding machine and an industrial robot.

In the past 20 years, Hwashi has obtained more than 50 patents for invention patents, utility model patents, design patents, and software Copyrights. It is the drafting unit of several national standards and industry standards. Hwashi has been awarded "China famous brand", "Guangdong famous brand", "China quality credit enterprise", "world outstanding Chinese businessman association member unit", "Guangdong province science and technology innovation quality management advanced unit", "Guangdong province academician expert enterprise workstation" and many other honorary titles.

For 20 years, Hwashi keeps innovating and follow up with the latest technology in the world. Invest heavily in product development and innovation every year. In cooperation with key universities and national key laboratories and engineering technology centers in new materials and processes, the "medium frequency inverter" technology was first introduced into resistance welding equipment. Help to realize the "unmanned, intelligent" factory, the practice we have been striving for is to create efficient, energy saving, safe and environmentally friendly production environment for customers.

With the trend of intelligent manufacturing in the world, Hwashi has set up a large-scale robot development base of 50,000 square meters in Yichun City, Jiangxi province. Introducing the world's top advanced production and processing equipment in our factory. We have a technical team and high-quality workers including mechanical, electronic, welding, automatic control, electromechanical integration, and management. We are committed to providing customers with efficient automation welding solutions in order to become a leading enterprise in world-class industrial intelligent equipment.

Crank-Arm Table Spot Welder

91.8% Response Rate

Double-Gun Table Spot Welder

91.8% Response Rate

Multi-Head Automatic Spot Welder

91.8% Response Rate