Машина для выдувного

- Категория: >>>

- Поставщик: Qingdao,Yankang,Plastic,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 178500.1 $* | 187425.28 $* |

| Aug-16-2025 | 177000.0 $* | 185850.4 $* |

| Jul-16-2025 | 148500.60 $* | 155925.8 $* |

| Jun-16-2025 | 174000.54 $* | 182700.17 $* |

| May-16-2025 | 151500.50 $* | 159075.2 $* |

| Apr-16-2025 | 171000.94 $* | 179550.67 $* |

| Mar-16-2025 | 169500.65 $* | 177975.21 $* |

| Feb-16-2025 | 168000.67 $* | 176400.10 $* |

| Jan-16-2025 | 166500.77 $* | 174825.78 $* |

Характеристики

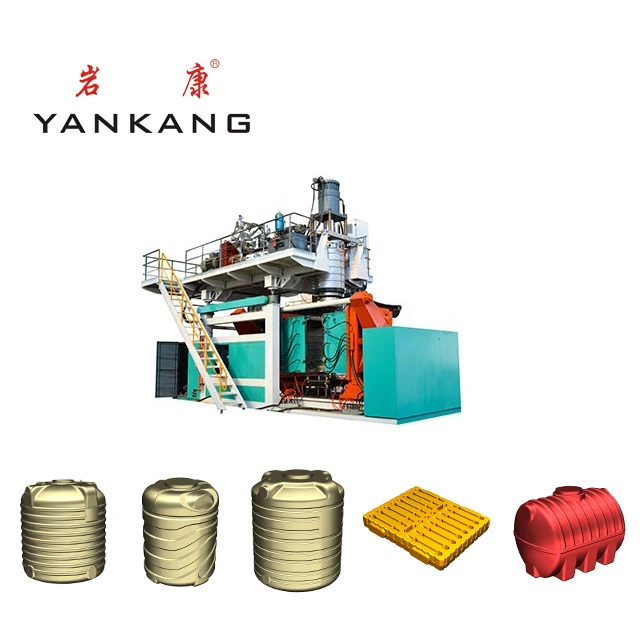

Plastic Jerry Cans Production Blow Molding Machine

Eco-friendly various models extrusion blow molding machine

500L blow molding machine used to produce range from 200L to 500L storage tank, with simple structure,convenient installation and operation,super high cost performance characteristics.

| PARISION CONTROL THINCKNESS CONTROL | MOOG | JAPAN |

| PLC | SEIMENS | GERMANY |

| TEMPERATURE CONTROL MODULE | SEIMENS | GERMANY |

| SERVO VALVE & SERVO TRANSDUCER | MIRAN | ITALY |

| INVERTER | SEIMENS | GERMANY |

| HYDRAULIC OIL SEAL | DZ | TAIWAN |

| INTERMEDIATE RELAY | OMRON | JAPAN |

| PNEUMATIC VALVE | AIRTECH | TAIWAN |

| HYDRAULIC PUMP & VALVE | YUKEN | JAPAN |

| PNEUMATIC SWITCH & CONTACTOR | SEIMENS | GERMANY |

| HYDRAULIC MOTOR & SCREW MOTOR | SEIMENS | GERMANY |

| REDUCER | GUOMAO | CHINA |

Details Introduction

1.Adopt Siemens PLC,Siemens Touch Screen and MOOG to make the blow molding machine to operate easy.

2.Adopt progressive hydraulic system by ourselves,easy to control.

3.Adopt servo motor to control the hydraulic system,saving a lot of energy.

4.The technology of Die Head is same with Germany.

5.Adopt new integrated Multi- layers die head design.from one layer to three layers.

After sales team

YanKang has rich experienced technical engineers team,which can provide timely, professional and high-efficient after sales service, including product introduction, installation, adjustment, maintenance ,technical training ,door-to-door service ,always online service by communication APP and etc.

Excellent qualified machine and satisfied after-sales service shows as below:

Before or in the early delivery period of the blow molding machine, professional engineer in YanKang will give a comprehensive and detailed training for customer’s technical and operating staff. Through their interacting with customers, answering some questions for customers, customers can be familiar with the blow molding machines, which can ensure a normal operation of the blow molding machine and a safe productive process.

If you have any quires about the machine ,We will help you in the shortest time, providing you with solutions through telephone or Internet. If necessary, We can also arrange technical stuff to give maintenance to the door.

Customers training

After the blow molding machine is sent to the customer’s facility, Yankang will send free commissioning engineers to provide technical training for workers in the customer’s plant and provide long-term technical support and upgrades and customers.

In the long term, we are constantly improving technology updates and innovating new project, and each blow molding machine by YanKang has a complete data bank, so we can do our best to provide you with remote technical updates, upgrades and other services, let your machine’s performance at all times in the best condition.

Our products

Water tank blow molding machine/IBC blow molding machine/double ring chemical blow mold molding machine /road barrier blow molding machine/pallet blow molding machine.Include the blow molding machine auxiliary and blow molds.