Флюидизированная сушилка для обработки

- Категория: Машины для обработки сахара и соли >>>

- Поставщик: EBR,METAL,MAKINE,IC,VE,DIS,TICARET,LIMITED,SIRKETI

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 119000.23 $* | 124950.76 $* |

| Aug-16-2025 | 118000.82 $* | 123900.84 $* |

| Jul-16-2025 | 99000.70 $* | 103950.54 $* |

| Jun-16-2025 | 116000.33 $* | 121800.87 $* |

| May-16-2025 | 101000.3 $* | 106050.17 $* |

| Apr-16-2025 | 114000.32 $* | 119700.66 $* |

| Mar-16-2025 | 113000.26 $* | 118650.87 $* |

| Feb-16-2025 | 112000.84 $* | 117600.71 $* |

| Jan-16-2025 | 111000.34 $* | 116550.20 $* |

Характеристики

Our salt production line includes many operations to salt production.All Our Products Can Customize Upon Customer Request. Prices can be change for other capacities.

· Fluidized Bed Dryer Capacity: 20 TPH

· Humidity of Inlet stream of Dryer: 2.5 – 3 %

· Humidity of Outlet Stream of Dryer: 0.05 – 0.12 %

· Total Amount of Weight of the System: 8 ton

· Energy Consumption of the System: 115 kWh

| \t | \t | |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

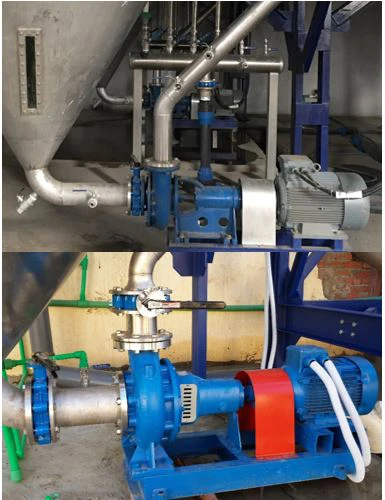

FLUIDIZED BED DRYER DETAILS

· Dryer chassis is made of ST 37 carbon steel, body and interior parts are made of AISI 316L stainless steel. The chassis has 3 sections. 1st section is chassis connected to the vibration engine and is going to be made 10 mm thickness. Support cross members are made of 12 mm thickness material. 2nd section is hot air chassis. It is going to be made of 5 mm thickness stainless steel. 3rd section is hood section and it is going to be made of 2.5 mm thickness stainless steel.

· All surfaces and fittings which are contact with the product are going to be made of stainless steel.

· Flange connections are going to confirm to standards.

· Dryer springs are going to confirm to standards and fittings are going to be 8.8 steel material.

· Inlet and outlet of dryer, outlet dust channels (pipes) are going to connect with compensator.

· Manholes are going to be made for the cleaning and entering. Permeability of the manholes is going to be provided. The manholes are going to be made easy opening and be resisted for the often uses.

· At the inlet and outlet hot air pipes the valves will install to close-open design and confirm to standards. At the exhaust outlet the valves are going to be made of stainless steel.

EBR SALT has been producing mechanical and PDV salt refining plants with its own production experience more than 20 years.

EBR SALT; produces all equipment which are use for salt refining plants at its own 2500 square meter closed total 5000 square meter factory.

EBR SALT produces; saturators, clarifiers, separators, crystallizers, blowers, thickeners, heat exchangers, harvesters, bunkers, conveyors, silos and storage systems, screw conveyors, cyclones, hydro cyclones, crushers, centrifuges, elevators, iodine and anti-caking systems, dryers, de-dusting systems, sieves and elimination systems, chemical dosing systems, packaging machines, tablet machines, licking stone (salt block) presses, etc.

EBR SALT has chosen to make our high-quality products easily accessible for everyone.

EBR SALT does not compromise on innovation, ethical behavior, reliability, on-time delivery, high quality and low-cost principles to achieve this goal.