Линия по производству бумажных пакетов с 4 цветными флексографскими

- Категория: Пакетоделательные машины >>>

- Поставщик: Ruian,Lilin,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.71 $* | 0.1 $* |

| Aug-16-2025 | 0.46 $* | 0.54 $* |

| Jul-16-2025 | 0.29 $* | 0.8 $* |

| Jun-16-2025 | 0.86 $* | 0.13 $* |

| May-16-2025 | 0.92 $* | 0.41 $* |

| Apr-16-2025 | 0.67 $* | 0.6 $* |

| Mar-16-2025 | 0.53 $* | 0.44 $* |

| Feb-16-2025 | 0.28 $* | 0.39 $* |

| Jan-16-2025 | 0.6 $* | 0.59 $* |

Характеристики

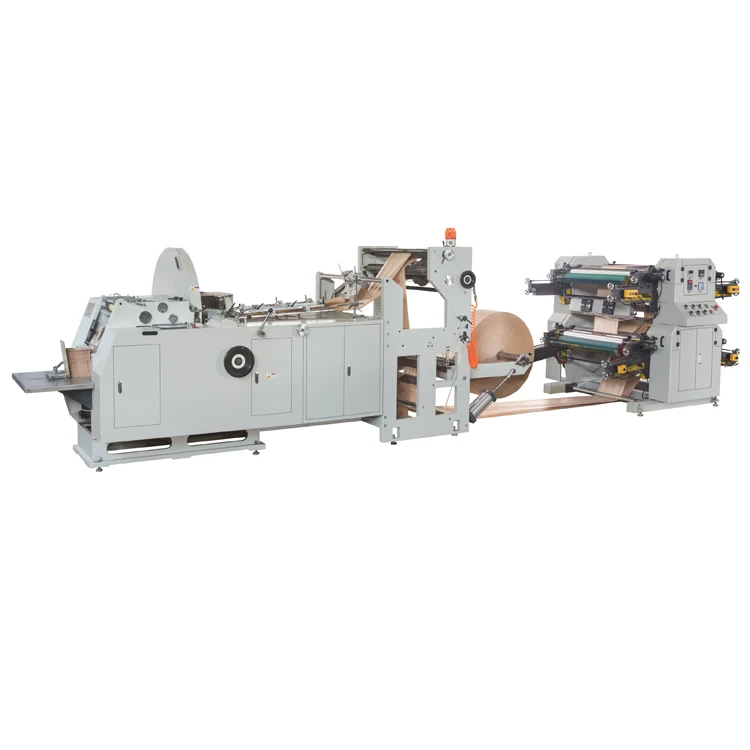

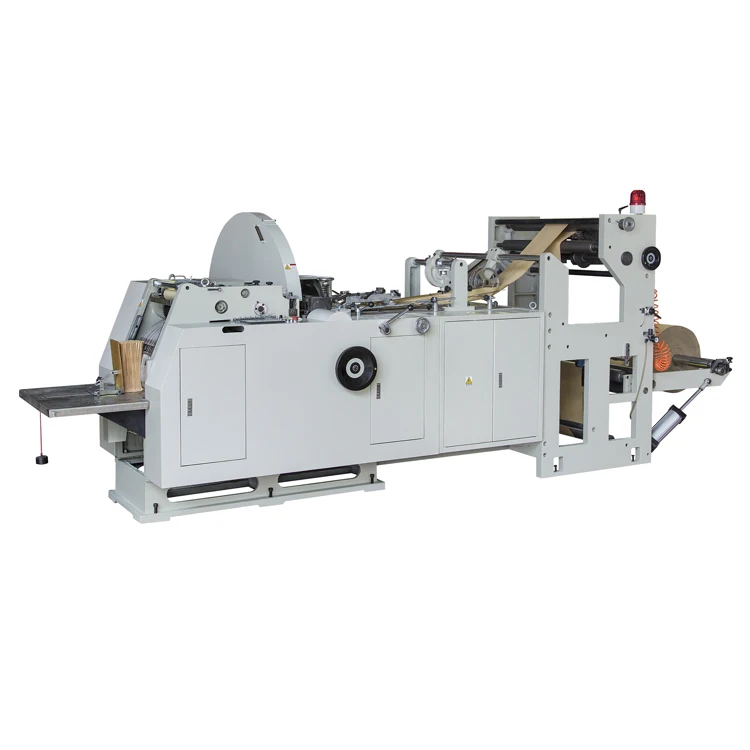

paper bag production line with 4 color flexo printing

LMD-400+YT-4800 Automatic High Speed Paper Bag Making Machine With Flexo Printing Machine

Introduction:

This bag machines making paper bags with flexo printing forms bags in one process from roll paper, printing, edge folding, tube forming, cutting, gluing, bottom folding,bottom gluing and finishing bag Easy operation, low power consumption, high efficiency. It is an ideal machine for producing food bags like bread bags, KFC bags and Mcdonald’s bags.

Features:

1. Controls bag length freely in a range through the human-machine interface

2. Adopt touch screen and PLC programmable control system, the work condition can be shown real time.

3. Equipped with an accurate photocell system for printed mark tracking

4. Color mark error stopping system

5. Double photoelectric sensor limit automatic correction control system

6. Material lifting adopt pneumatic lift structure.

7. Accurate color tracking system, color errors automatically shut down.

8. Automatic lubrication system

9. accurate colour register.

10. Lift and lower the printing plate cylinder Automatic, it will automatically stir the printing ink after lifting.

11. The printing ink is spread by the knurled cylinder with even ink colour.

Video: https://youtu.be/lgGEgeV2P40

Contact:

Website - www.lilinmachinery.com

Email- Lilin3 at lilinmachinery.com

Trade Manager - cn1525656379jutb

Office Phone:+86 577 65023567

Mr. Yao

Cellphone/Wechat: +86 13735586219

Specifications:

Type | LMD-400+YT-4800 | |

Cutting Length(C) | 150-460 mm |

|

Bag Length(H) | 140-450 mm | |

Bag Width(L) | 70-280 mm | |

Gusset depth(S) | 0-50 mm | |

Standard flap(P) | 12-20 mm | |

Max. Speed | 400 pcs/min | |

Max. reel weight | 400 Kg | |

Max.Roll Diametr | 1000 mm | |

Reel inner diameter | 76 mm | |

Paper specification | 30-80 gsm | |

Printing Color | 4 Color | |

Printing Width | 720 mm | |

Printing Length | 200-800 mm | |

Max.Printing Speed | 80 m/min | |

Overprint Precision | ±0.2 mm | |

Thickness of Plate | ||

Web edge control system | Double photoelectric automatic correction control system | |

Web tension control system | Automatic constant tension control system | |

Air pressure | ≥0.12cmm, 0.4~1Mpa | |

Driven motor | Double servo motor | |

Electric | 380V, 50Hz, 3 phase | |

Power | 9KW | |

Weight | 4700Kg | |

Overall dimension | 6700×1650×1850 mm | |

Configuration:

| 1. Adopt touch screen and PLC programmable control system, the work condition can be shown real time. Cooperate with the ultra precise double servo motor, the stability can be guaranteed. |  |

| 2. The machine has automatic counting system. The user can set a number to count. When bag quantity meets the number, the bag will be jumped out like the picture shows. | |

| 3. Adjustable bottom gluing system makes the adjustment of different gluing specification very easy. |  |

| 4. Lower glue tank structure can use the glue directly. The glue doesn’t need glue thickener to increase viscosity. The structure can improve efficiently the phenomenon that the high viscosity glue makes bag bottom fold. The gluing will be evener. Solve the problem that the upper glue tank structure leaks glue when the machine run with slow speed. | |

| 5. Cutter positioning structure makes the cutter dismounting very easy. Installation of cutter does not need complicated adjustment. |  |

| 6. Cutter safety shield protection switch can avoid the danger that user forgets to close the shield when machine runs with high speed. | |

| 7. The paper tube forming system can be adjusted as a whole. It can increase the work efficiency and stability; reduce the waster rate during the producing; and save time of adjusting. |  |

| 8. Precise color mark tracing system can make sure precision of bag printing pattern cutting position. The color mark tracing function can avoid the readjustment after paper reel changing, paper web breaking, or power outage. The machine can stop automatically when the color mark is error. It will save time and reduce the waster rate. |  |

| 9. Automatic edge control system adopts two photoelectric sensors to detect the edge of paper web. The motor doesn’t need to work often so its power consumption is reduced and its life is extended. (User can choose single photoelectric sensor to control edge.) |  |

| 10. Pneumatic paper reel lifting device make paper reel changing easy. Press one switch and the paper reel will be lifted automatically. Avoid the personal injury. The pneumatic lifting system can make sure the stability of paper web feeding and avoid moving the feeding stand. |  |

| 11. Automatic lubrication system can supply automatically the lubrication oil to every part which needs to be lubricated. The lubricating time and oil quantity can be set by user. Avoid damage of machine because user forgets to lubricate. The maintenance becomes easy! |  |

| 12.Lift and lower the printing plate cylinder Automatic, it will automatically stir the printing ink after lifting. |  |

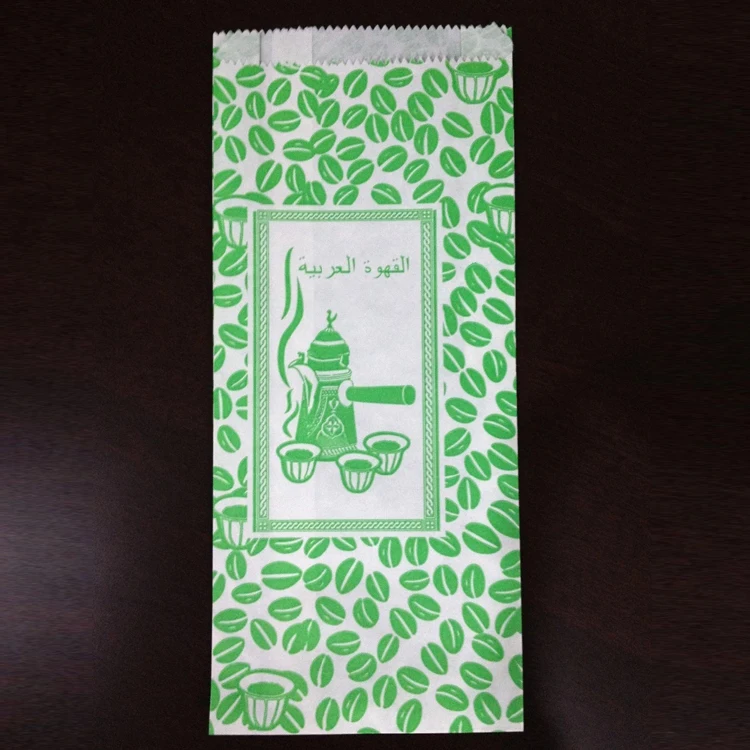

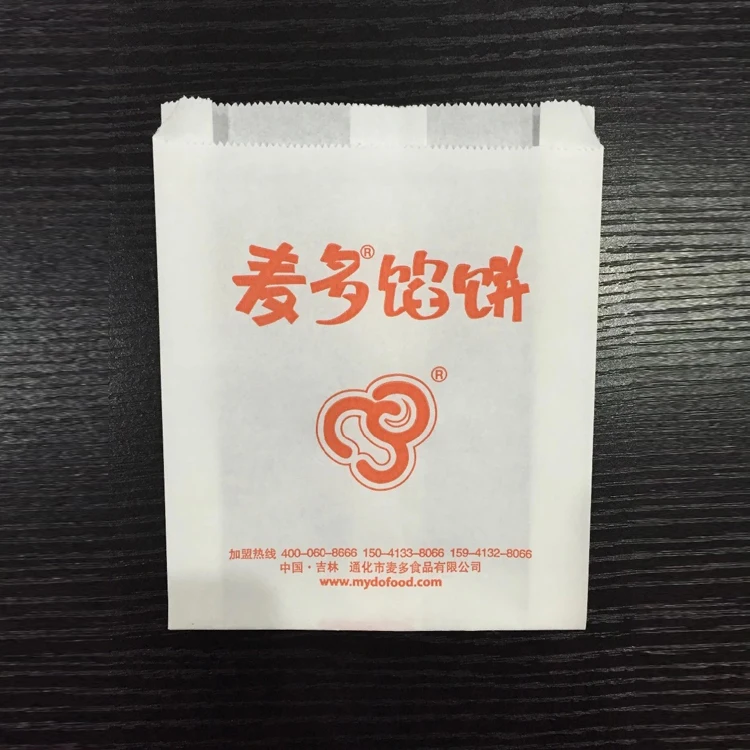

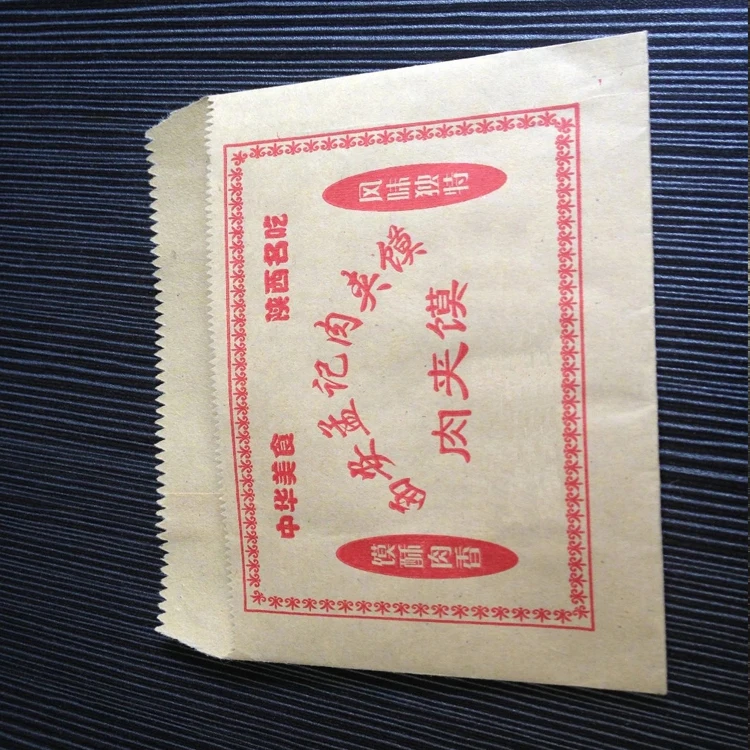

| 13. Products of the paper bag production line with 4 color flexo printing: |  |

Our Services:

| 1. Installation and operation training; on-the spot teaching; instruction manual and video |

| 2. Field installation,field maintenance and repair service |

| 2. One year warranty; life-long maintenance |

| 3. Engineers available for overseas service all year round |

| 4. Quick-response on-line support; some models of our machines are monitorable via internet |

Delivery and Warranty:

DELIVERY PERIOD | Approximately 45 days from the date of receipt of deposit, subject to reconfirmation or change when order is acknowledged. |

LOADING PORT | Ningbo, Shanghai |

PAYMENT TERMS | T/T, L/C, trade assurance, western union, cash, etc. |

INSTALLATION | All bag making machines have been finished all adjustment in our workshop, installation personnel is not needed. If buyer needs our engineer to install the machine in site, the charge (VISA, accommodation, food, round air-tickets and salary 50USD/day) shall be paid by the buyer in case. |

TEST MATERIALS | The buyer should prepare an adequate supply of test materials; our company does not have responsibility for undertaking any testing of materials and costs. |

ELECTRICAL EQUIPMENT | Unless other noted, the machine needs electric of 380V, 3 Phase, 50/60 Hz. Consult factory for special electrical requirements. |

WARRANTY | The factory guarantee that we supply new (unused) paper bag forming machines, and we offer warranty of 12 month. In this period, we will supply free parts which are broken because of quality. We don’t offer warranty for wrong operation (including changing software of PC & HMI). |

FAQ:

| 1. Q: Are you trading company or manufacturer ? | A: We are manufacturer with our own factory and workers. |

| 2. Q: How long has your factory been in this field ? | A: As one of the leading paper bag machinery manufacturers in China, we have more than 12 years of experience of designing and producing paper bag machines. |

| 3. Q: Where is your factory ? How can I visit it? | A: Our factory is located in Ruian City (Wenzhou), Zhejiang Province, China. The nearest airport is Wenzhou Airport, 40-minutes' flight from Shanghai Pudong Airport (or 4 hours by train). |

| 4. Q: Samples available ? How can I get them ? | A: Sample bags or handles are available, but freight need to be paid by our customers. |

Samples of the paper bag production line with 4 color flexo printing:

Factory of Lilin paper bag machine: