10 т/день машина для непрерывного литья

- Категория: Metal Casting Machinery >>>

- Поставщик: Wuxi,Jintong,Furnace,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.33 $* | 0.11 $* |

| Aug-19-2025 | 0.13 $* | 0.26 $* |

| Jul-19-2025 | 0.79 $* | 0.34 $* |

| Jun-19-2025 | 0.11 $* | 0.32 $* |

| May-19-2025 | 0.73 $* | 0.68 $* |

| Apr-19-2025 | 0.46 $* | 0.97 $* |

| Mar-19-2025 | 0.53 $* | 0.96 $* |

| Feb-19-2025 | 0.93 $* | 0.57 $* |

| Jan-19-2025 | 0.74 $* | 0.10 $* |

Характеристики

This type of furnace is based on the current die casting and casting market to meet the characteristics and requirements abroad. We improve manufacturing quality, strictly control the processing temperature, reduce defects caused by temperature fluctuations, and especially improve the structure of the furnace body, and Italy Baide brand gas engine will be set according to the process temperature requirements. According to the production needs, the furnace type uses imported graphite crucible to greatly improve the utilization rate of the furnace, or it will use casting iron crucible for holding and casting purpose. It is mainly used for melting and smelting aluminium ingots, aluminium alloy scrap and scrap after metal cutting.

Parameters:

1\tUsage: continuous melting

2\tFuel used: natural gas, calorific value 8600Kcal/m3

3\tMaximum gas consumption: 45Nm3/h

4\tMinimum gas consumption: 17.5Nm3/h

5\tMaximum air supply pressure: 50mbar

6\tMinimum air supply pressure: 20mbar

7\tMelting aluminium liquid discharge temperature: 650 ℃

8\tEnergy consumption index (natural gas) : 12 to 15 nm3 / tons of aluminium by continuous operation condition and base on actual calorific value and under rated working conditions

9\tFurnace body surface temperature: ~50 ℃

10\tRated Temperature: 650℃

11\tContent: 4000KG

12\tMelting rate: 3000kg/2hours/loading

13\tBurner power: 0.3KW

14\tRated voltage: 220V

15\tPower frequency: 50HZ

16\tCrucible size: φ1160×1245H

17 \tFurnace body diamesion: ~ ¢2000×H2050mm

18 \tWeight: ~6T

Part II: Working Condition

1. The environmental temperature 5 ℃ ~ 45 ℃.

2. Relative humidity of the workshop: no more than 85%

3. Elevation of the plant location: according to the actual factory

4. Power supply: ac 380 +- 10%, 50HZ +- 2%

5. Working system: 251 days/year, 7 hours/shift, 3 shifts per day.

6. Plant height: according to the actual situation of the factory

7. Workshop gate: according to the actual situation of the factory

8. Crane capacity: 5 tons.

9. Natural gas: gas pressure is greater than or equal to 30KPa

PART III: Item\tSpecification\tQty\tBrand

Miniature air circuit breaker\tDZ47-63/3P/16A\t1pc\tSchneider

fuse protector\tRT14-20/6A\t1pc\tSchneider

control switch\t\t1pc\tSchneider

a.c. contactor\tB9-3010/220V\t2pcs\tSchneider

general-purpose relay\tJTX-2C/220V\t3pcs\tSchneider

24 hours customer service

High quality raw material

High quality raw material

Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Furnace Making

Furnace making

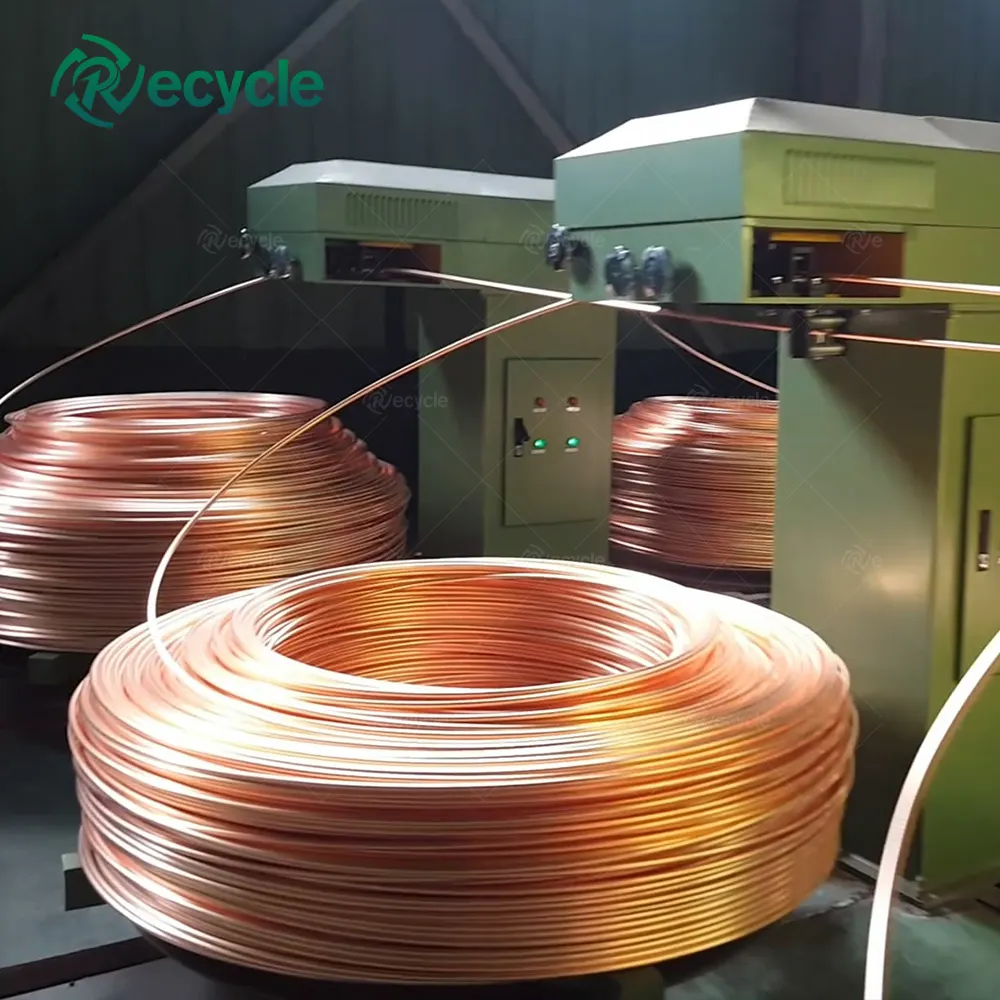

Wuxi Jintong Furnace Co., Ltd. called Wuxi Xinlian Furnace Factory before was established since year 2004, having 10+ years experience in metal melting and metal heat treatment area. Jintong Manufacturing Corp. is specialized in manufacturing induction melting furnace(copper scrap brass scrap, aluminium scrap, zinc scrap, bronze scrap, steel, iron, stainless steel, carbon steel scrap and precious metal like gold or silver). Our furnaces can be applied to many fields such as copper/brass rod/pipe continuous casting, zinc ingot, aluminum rod continuous casting or power resistance.

We sincerely invite you to visit our factory and offer your valuable guidance. Looking forward to cooperating with you.

.

Please provide us with following basic information:

What product you want to make?

What kind of raw material do you have? (Pictures are very appreciated)

What capacity do you need, daily, monthy or yearly?

What is the working hours there every day?

Whatsapp/Wechat/Skype: 0086 15906188353

Email: eva at jintongindustry.com

A. 1 set.

Q. Your company is a trading firm? or Factory?

A. We are a factory with 10+ years experience in industrial melting feild. We currently have three branches: main frequency furnace production, medium frequency furnace production, component machine production. You are warmly welcomed to visit our factories.

Q. How is your products quality?

A. As a manufacturer, we have our own R&D team. Basing on several years of technical innovation, we have accumulated successful experience in induction heating, temperature holding, fast melting. We've customized so many furnaces with all positive feedbacks.

Q. What kind of material our furnace can melting?

A. Jintong is able to supply a melting production line such as copper/zinc/aluminum melting line.Jintong medium frequency furnace can also melt iron, steel, gold, silver and so on.

Q. I am not so familiar with your machine now. I am not sure I can use it well if I buy it from you.