Бумажный фильтрующий механический внутренний очищающий фильтр для

- Категория: Фильтр для воды >>>

- Поставщик: Shanghai,JCI,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.75 $* | 0.68 $* |

| Aug-16-2025 | 0.43 $* | 0.17 $* |

| Jul-16-2025 | 0.92 $* | 0.7 $* |

| Jun-16-2025 | 0.7 $* | 0.19 $* |

| May-16-2025 | 0.58 $* | 0.63 $* |

| Apr-16-2025 | 0.33 $* | 0.63 $* |

| Mar-16-2025 | 0.87 $* | 0.83 $* |

| Feb-16-2025 | 0.57 $* | 0.23 $* |

| Jan-16-2025 | 0.58 $* | 0.77 $* |

Характеристики

All our certifications are REAL ONE.

NOT FAKE, NOT FAKE, NOT FAKE!!!

Please contact us to show you!!!

Paper-making Filtration Mechanical Internal Scraping Self Cleaning Water Filter

1. AFM Filter is a new type of self-cleaning strainer independently developed by Shanghai JCI company with our own intellectual property. It is designed for continuous online filtration to remove impurities on the outer surface of filter screen via highly-efficient mechanical scrapping.

2. AFM Filter is mainly designed for high-viscosity and soft impurities filtration, with the precision range being 50-1,500μm. Featuring precise filtration can effectively remove impurities from the surface of filtering screens, thus removing more impurities with high efficiency. It applies to the filtration of water and various viscous liquids. AFM Filter designed and manufactured as per Shanghai JCI's standards for high performance, high quality and high reliability, it features internationally first-class quality.

3. Traditional filters easily get blocked when used to filtrating viscous materials and soft impurities. For this reason, large-sized filters are usually selected or manual cleaning is frequently conducted, resulting in heavy investment, heavy work and serious waste of materials. Such problems can be easily solved by AFM Filter with advanced self-cleaning mode. It can regularly maintain cleanness of filtering screens and expel waste fluid containing high-concentration impurities, thus reducing waste of materials. It has evident advantages and higher efficiency in filtrating poor-quality water and viscous materials such as adhesive, resin, polymer, coatings and grease. AFM Filter with notable technical advantages and low operation costs, it has gradually displaced the traditional manual filters in various fields, such as vibrating screeners, bag filters, basket filters, etc.

Product Details Show

How Does It Work?

Filtering status(see figure 1)

Liquid flows inside from the inlet.The liquid flows outwards from the inner surface of the filter screen, and the impurities are intercepted on the inner surface. Then, the liquid flows out from the outlet; with the passage of time, the impurities gradually increase, and differential pressure rises. We can begin to clean the filter screen according to the preset differential pressure or the timing.

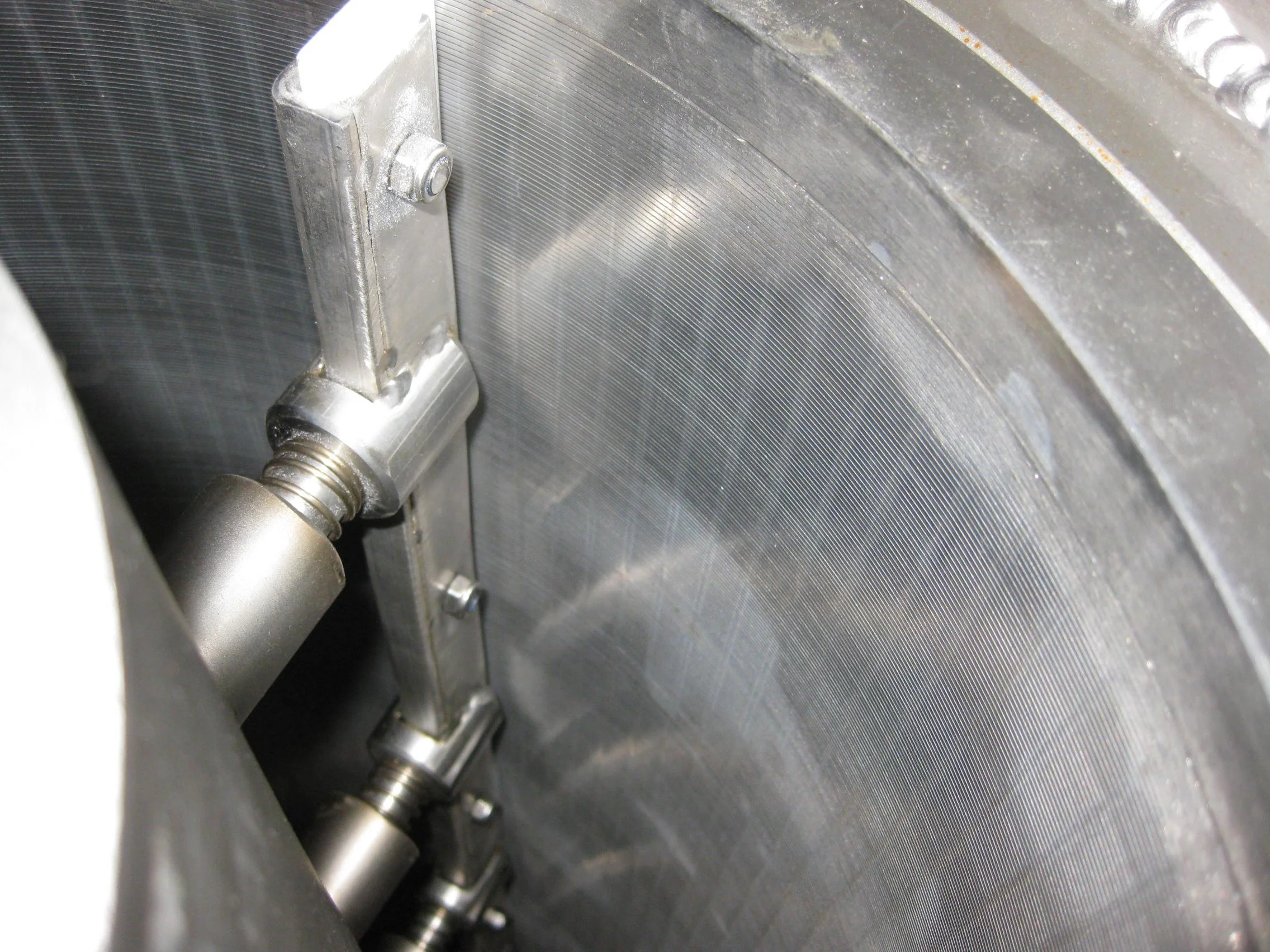

Cleaning status(see figure 2)

The motor drives the scraper to rotate horizontally to clean the filter screen. When the scraper rotates, impurities are scraped off and filtered along the filter net to the bottom of the filter, and the impurities with large specific gravity are deposited into the dirty collector. Each cleaning is made up of a number of strokes. After the filter screen is cleaned, the filtering ability is restored. No filtration interruption while self-cleaning.

Discharging status(see figure 3)

After a number of cleaning cycles, impurities accumulate to a certain amount. Regular opening of drain valve, and the waste liquid containing high concentration of impurities is discharged. which can also be recycled, if necessary.

Technical Parameters & Specifications

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

Technical features and advantages

1. Horizontal rotary scraping, scraping off the impurities directly, is good at filtering viscous liquids and removal of viscous, soft and suspended impurities;

2. Simple structure, easy dismounting; after removing the scraper, easy to take out the filter screen, and easy to clean the inside;

3. Automatic operation, continuous online filtration, to end up the heavy filter screen replacement and cleaning work;

4. Do not produce disposable filter material, saving consumables costs and environmental costs;

5. Small filtration pressure loss, stable flow rate, energy saving is beneficial to the continuous stability of the whole process;

6. Sealed filtration, preventing dangerous material leakage, is advantageous to the safe production and the staff health;

7. Discharge waste liquid with high impurities concentration can be recycled, to reduce the loss of high-value materials;

8. A variety of advanced control systems are optional, powerful, efficient and reliable;

9. Selection of world-renowned brands of components, high reliability, low costs.

Automatic Cleaning Control System

| \t | |

| \t | |

| \t | |

| \t | |

| \t | |

| \t | |

| \t | |

| \t | |

| \t |

Product Application

Part of Applicable Industries

Applicable fluid types: Resin, coatings, polymers, adhesive, citric acid, fermentation liquor, chitosan, cosmetics, sepharose, silicone solution, soap, sorbitol, steroids, cereal syrup, wet end aids, pigments, lubricant, rubber, ethanol, mixed oil, edible oil, hot fry oil, fruit juice, diesel, etc.

Filtration effect: Constant-value screening, removing large particles, purifying fluid, and protecting key equipment.

Filtration type: Mechanical online scraping filtration.

Professional marketing personnel

1. At least 2 months of technical product training before work.

2. Reply your inquiries in 5 minutes; submit the competitive price in 2 hours.

3. Business English major and Communicate smoothly.

Professional design team

1. Custom-built filters to meet your project requirements.

2. Design in 2 hours for free.

3. After sales service engineers available to service machinery overseas or making phone calls. Solving problems in 1 hour.

We are factory

1. Self-marketing.

2. We have strict control on all processes ranging from R&D design, production, inspection and after-sales service.

3. Warmly welcome to our factory for a visit.

We have a large group of excellent technical personnel concentrating on filtration R&D. The company has strict control on all processes ranging from design to production, inspection and after-sales service as conducted by its well-experienced engineers. The awareness of quality and service as well as the spirit of detail-focused manufacturing has been penetrated into every detail of the company. Through carrying out scientific and normative management and establishing follow-up service archive for every product, we can ensure that every product and every detail of it is excellent, safe and reliable.

We are a global professional company. Over the years, we have possessed many R&D, management and manufacturing centers, marketing and service networks throughout the world. Headquartered in Shanghai, the company has two production bases in Kunshan, Jiangsu and Taiwan, China, and has agents in Singapore, Malaysia and Myanmar, etc. In the future, JCI will become a leader in the field of automatic filtration system and industrial purification technology, to enable efficient and safe filtering products to serve the whole world.

Sawing Process

Lathe Machining

Welding Process

Sand Blasting

Assembling

Delivering