Серия QVC зернистый пневматический вакуумный подъемник переносной питатель конвейерная система для

- Категория: Conveyors >>>

- Поставщик: Dandong,Flight,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 1547.2 $* | 1624.29 $* |

| Aug-17-2025 | 1534.45 $* | 1611.24 $* |

| Jul-17-2025 | 1287.22 $* | 1351.72 $* |

| Jun-17-2025 | 1508.86 $* | 1583.55 $* |

| May-17-2025 | 1313.55 $* | 1379.67 $* |

| Apr-17-2025 | 1482.53 $* | 1556.47 $* |

| Mar-17-2025 | 1469.8 $* | 1542.63 $* |

| Feb-17-2025 | 1456.81 $* | 1529.96 $* |

| Jan-17-2025 | 1443.40 $* | 1515.74 $* |

Характеристики

——Hot Sale Products——

QVC Series Grain Pneumatic Vacuum Lifter Transfer Feeder Conveyor system for Powder

——Description——

Air drive vacuum feeder use the air compress air through the vacuum maker get the sure vacuum to transfer the material. The mechanical vacuum pump is no need. The machinery structure is simple, Cubage is small, avoid repair, low noise. Control is convenient, clear up the material static and covers the GMP standard. Vacuum maker get the pure vacuum. Make the transfer material avoid the separate layer, guarantee the material is homogeneous. So the machine is first choice to tablet press, capsule filling machine, dry granulator, packing machine, pulverizer and vibration sieve etc.

When the compress air supply to the vacuum maker. It produces the negative pressure come into being the vacuum airflow. The material is absorbed inbreathe the material jaws. Form air flow, through the inbreathe material jaws to the material storehouse of the material feeder. The filter separates the material and air. When

the material storehouse is full, the controller shut power. The vacuum stop working.

Same time the gate of material storehouse open. The material fall into the feeder of the relate machine. Then the compress air through the pulse clean the filter. Waiting for the time coming or the get the signal form the material level sensor, the feeder restart.

Product picture

The Vacuum Charging Machine uses the swirl pump to extract the air to put the feed nozzle and the whole part in certain vacuum situation. Particle materials is inhaled into the feed nozzle accompanied by the outer air and forms materials air current going into the hoist through the gripping pipe. After the air and the materials are separated in the hoist, the raw materials go into the material receiving trough. Feeding materials—emptying materials is completed by opening and closing unceasingly pneumatic change valve that is controlled by control centre.

The Vacuum Charging Machine has the compressed air reversed-blow device. When emptying the materials, compressed-air pulsar blows the filter reversely and blows away the powder attach to the surface of the filter in order to make the charge work normally.

——Technical Parameter——

Model | Production capacity | Air consumption | Air pressure | Overall size |

QVC-1 | 180 L/m | 0.4-0.6 MPa | 140 x 560 | |

QVC-2 | 700 kg | 360 L/m | 0.4-0.6 MPa | 213 x 720 |

QVC-3 | 1500 kg | 720 L/m | 0.4-0.6 MPa | 290 x 850 |

QVC-4 | 3000 kg | 1440 L/m | 0.4-0.6 MPa | 420 x 1150 |

QVC-5 | 6000 kg | 2880 L/m | 0.4-0.6 MPa | 420 x 1150 |

QVC-6 | 9000 kg | 4320 L/m | 0.4-0.6 MPa | 420 x 1350 |

Products advantages | 1. We always give top priority to quality 2. Strictly guarantee the precision of parts error 3. Reasonable processing technology coupled with advanced processing equipment |

Trade advantages | 1.Our company is a Gold Supplier on Alibaba. So we can provide Escrow Service on Alibaba. 2.Our company can do Trade Assurance Order for customers on Alibaba. |

Custom made advantages | 1.The company independent research and development, custom design exclusive for the series of products. 2. Mutual benefit with the best quality and service, and sincerely hope that friends from various circles at home and abroad sincere cooperation and mutual benefit and win-win situation. |

Company Introduction

——Our Company—

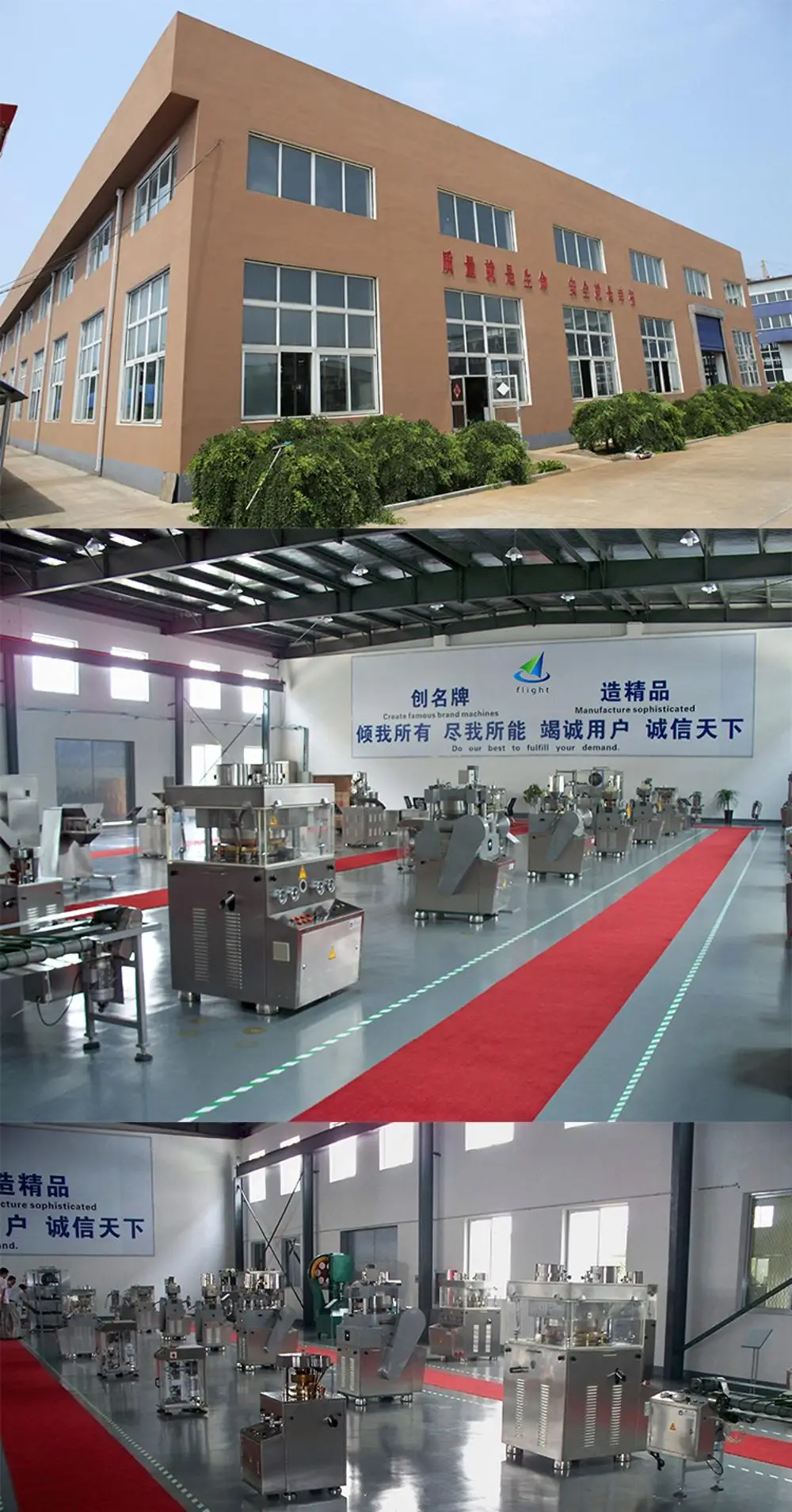

Flight Pharmaceutical Machinery CO., Ltd is the professional manufacturer and export of

various pharmaceutical machineries in China. Our company has profuse designs with series

quality grade, and expressly, our price is very competitive, because we are manufactory.

Our factory developed about forty types of machines in over ten varieties. By ISO9001:2000

quality system attestation, accord with GMP attestation request. All tasks from casting to

metal machining, and general assembly are accomplished ourselves.

We produce and export various pharmaceutical machineries, relevant medicament detecting

instruments and packing machinery, such as Rotary tablet press, Single punch tablet

press, Pulverizer, Mixer,Coating machine, Granulator, Labeling machine, Liquid filling

machine, Capsule filing machine, Blister packing machine, and so on.

We have professional export office, with an experienced and professional team, they will

service in whole business. By excellent quality, reasonable price and perfect after-service,our

products have been sold in many countries and regions all over the world, Such as United

States, Canada, Australia, United Kingdom, Bulgaria, Russia, Indonesia, Pakistan, Thailand

and Vietnam etc, these products are very popular with the customers there.

Try to do everything, let customer satisfaction, this is our company’s service tenet.

<<Welcome new and old customers come to discuss business>>

——Our Customer——

——Packing & Shipping——

Delivery time | Within 30 days after receiving the payment. |

Payment methods | T/T or Western Union payment, and full payment before shipping |

Guarantee | One year quality guarantees and free with spare parts for one year. |

After sales service | The English user manual Circuit diagram |

Back home

To know more information about our company