Стандартная азотная термофляга из жидкого азота Dewar

- Категория: Сосуды высокого давления >>>

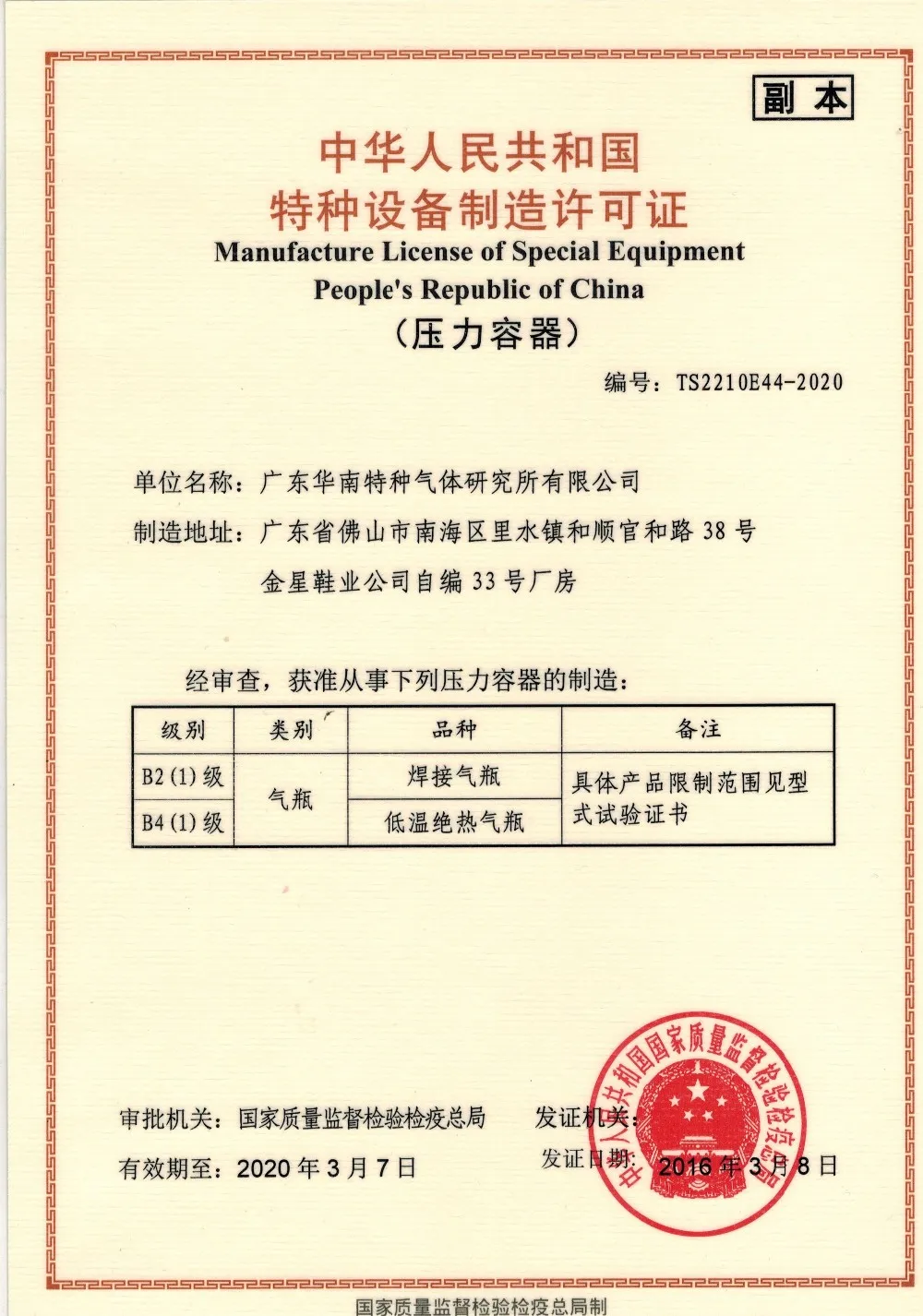

- Поставщик: South,China,Special,Gas,Institute,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.26 $* | 0.39 $* |

| Aug-17-2025 | 0.42 $* | 0.31 $* |

| Jul-17-2025 | 0.69 $* | 0.13 $* |

| Jun-17-2025 | 0.8 $* | 0.10 $* |

| May-17-2025 | 0.55 $* | 0.92 $* |

| Apr-17-2025 | 0.85 $* | 0.6 $* |

| Mar-17-2025 | 0.67 $* | 0.32 $* |

| Feb-17-2025 | 0.96 $* | 0.32 $* |

| Jan-17-2025 | 0.22 $* | 0.96 $* |

Характеристики

The DPL series containers are vacuum insulated, Stainless steel containers designed to store and transport cryogenic liquid oxygen, nitrogen or argon. Containers may be used for over the road transportation of cryogenic fluids, as well as on-site storage and supply in a wide range of applications.

As rugged, long holding time, self-contained gas supply systems, these cylinders are capable of providing continuous flow rates of up to 9.2 cu.m/h, with a delivery pressure of approximately 100psig (6.9bar/690Kpa).

DPL-175L/195L/210L-1.4Mpa Technical Specification | ||||||

Product Model | DPL-175L | DPL-195L | DPL-210L | |||

Diameter*Height(mm) | 508*1500 | 508*1620 | 508*1707 | |||

Working Pressure(MPa) | 1.40 | 1.40 | 1.40 | |||

Pressure Relief Valve(MPa) | 1.59 | 1.59 | 1.59 | |||

Inner Container Bursting Disc(MPa) | 2.60 | 2.60 | 2.60 | |||

Maximum Liquid Capacity(L) | 175 | 195 | 210 | |||

Usable Liquid Capacity(L) | 166 | 185 | 197 | |||

Normal Evaporation Rate ((LN2)) | ≤2.1% | ≤2.1% | ≤2.1% | |||

Tare Weight(Kg) | 110 | 117 | 123 | |||

Max. Filling Quality Oxygen(kg) | 172 | 191 | 205 | |||

Max. Filling Quality Nitrogen(kg) | 121 | 135 | 145 | |||

Max. Filling Quality Argon(Kg) | 208 | 233 | 250 | |||

Max. Filling Quality Natural Gas (Kg) | 70.1 | 76 | 86.3 | |||

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Main Features

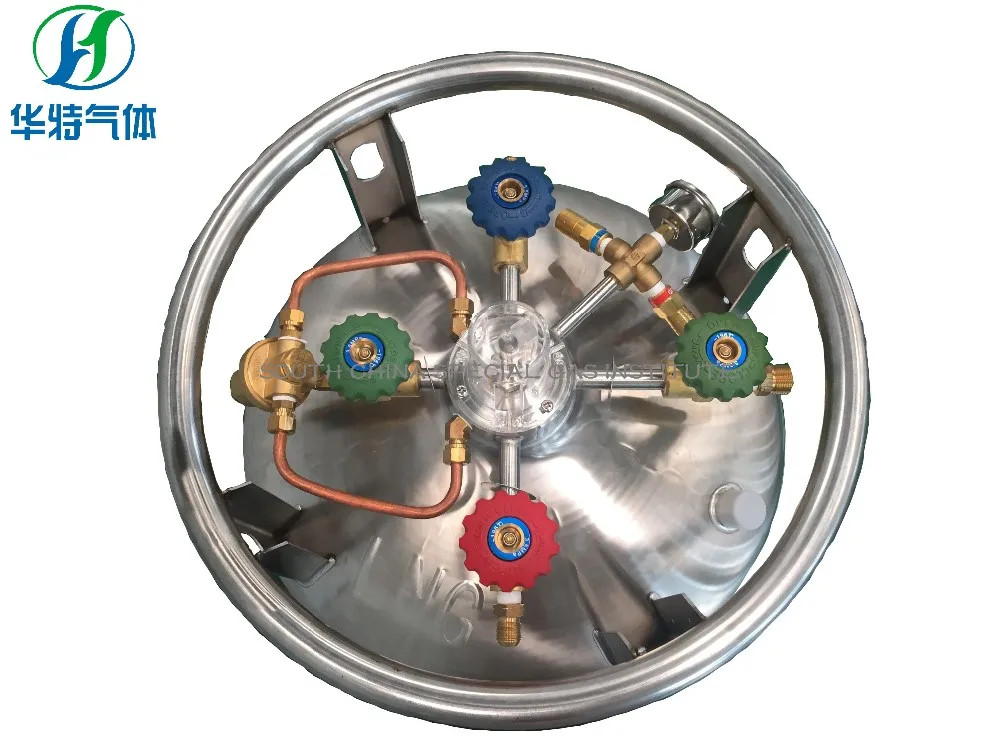

Name: Handling wheel & outer upper cover

Feature: the handling wheel is welded firmly and smoothly

the head cover is torispherical head,made by cold stamping, No splicing, the whole cover real thickness NOT less than 2.15mm and under refined polsh processing.

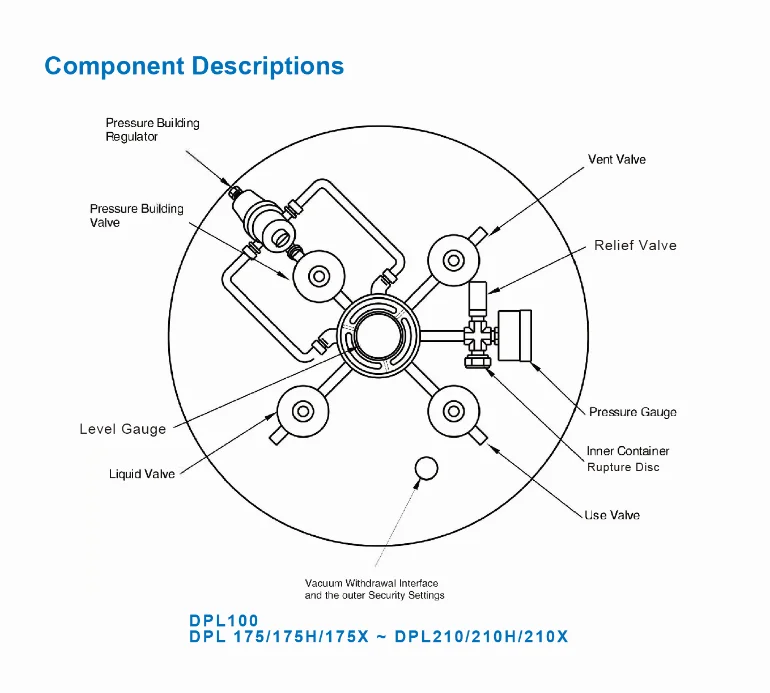

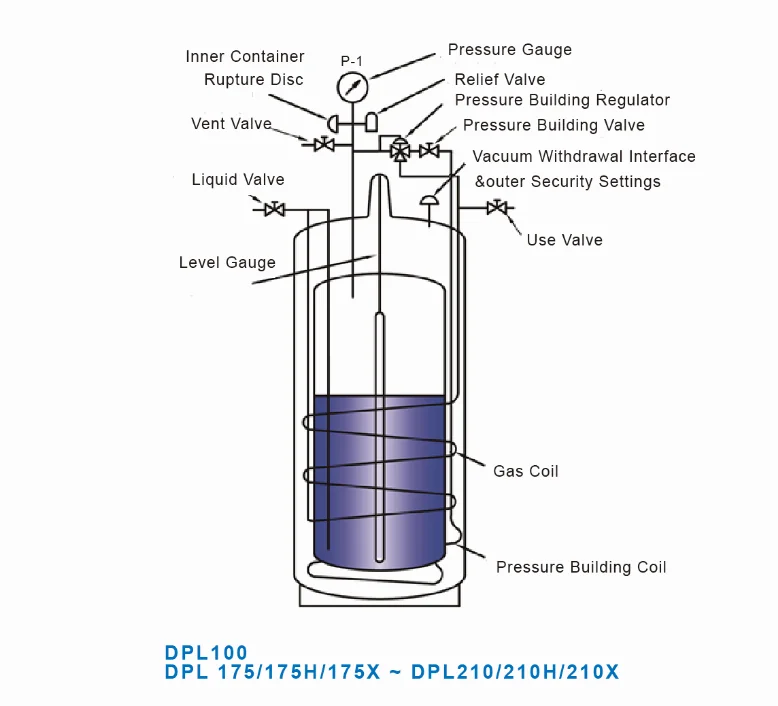

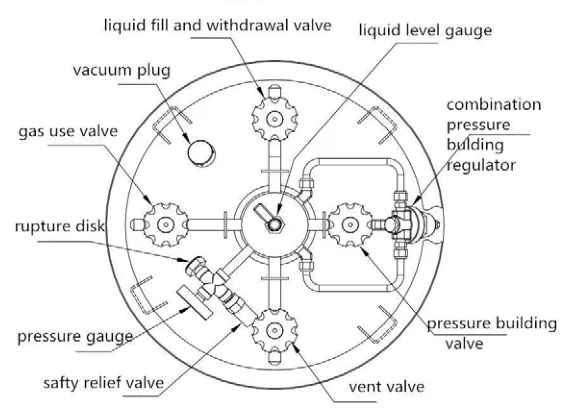

inner Structure

Name: Interlayer Thermal Insulstion.

Feature: There is thermal barrier of high technology in the interlayer, it includes efficient thermal barrier, vacuum and vacuum support system, which are useful for working life. Thermal barrier of high technology can stop the heat from entering the inner container by the way of thermal radiation and thermal conduction, vacuum can stop the heat from entering the inner container by the way of thermal convection

Main Features

Feature: Any Sudden drop, tip-over will bring abuse or dents to cylinder,which would affect the insulation system, while Carbon Steel or 304SS Rack with Wheel will make great convenience for users to transport or move the cylinder protect the cylinder from sudden damage.