Лучшая машина холодного прессования фанеры для деревянных

- Категория: Press >>>

- Поставщик: Linyi,Ruifeng,Machinery,Factory

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 765433.79 $* | 780742.76 $* |

| Jul-19-2025 | 620784.57 $* | 633200.73 $* |

| Jun-19-2025 | 753379.98 $* | 768447.17 $* |

| May-19-2025 | 747352.46 $* | 762299.16 $* |

| Apr-19-2025 | 596676.62 $* | 608610.68 $* |

| Mar-19-2025 | 735298.8 $* | 750004.74 $* |

| Feb-19-2025 | 729271.34 $* | 743856.67 $* |

| Jan-19-2025 | 723244.24 $* | 737709.41 $* |

Характеристики

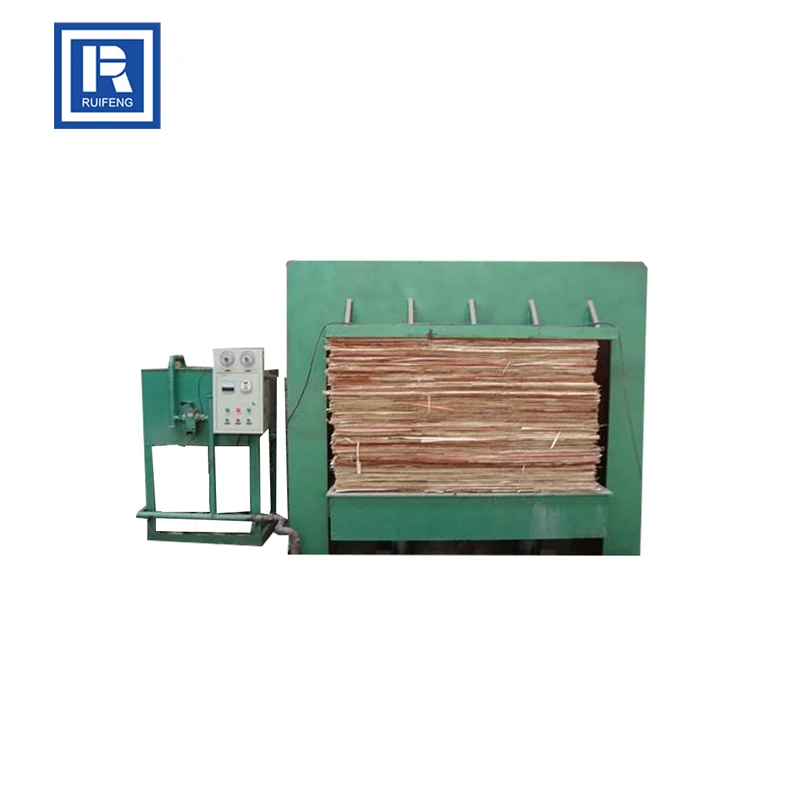

Better plywood cold press machine for wooden doors

The machine, pre-press also named cold press,is used for plywood production.

Here is 400T cold press is listed as follows:

| Name | plywood cold press machine |

| Apply for | plywood cold press |

| Nominal pressure | 400T |

| Feeding direction | Horizontal |

| Hydraulic cylinder diameter | φ320mm*2 |

| Hydraulic cylinder stroke | 1800mm |

| Hydraulic pump working pressure | 25Mpa |

| Working platen size | 2700*1370mm |

| Daylight distance | 1800mm |

| Motor | 22.5kw |

| Control system | PLC automatic pump station |

| Cossbeam | 800*30*10mm Q235 steel plate |

| Pillar | 350*10*10mm Q235 steel plate |

| Movable crossbeam | 400*20 Q235 steel plate |

| Control system | PLC automatic pump station |

Cold press machine is the auxiliary in plywood production line, which is used to shorten the cycle time of hot press and improve the quality of plywood before gluing board. Cold press machine belongs to the pressing machine. Cold press machine is mainly used to press the gluing veneer, so that make the initial shape, and then into the hot press machine to press. It is important to improve the quality of plywood, and it is an significant part. Cold press machine in general consists with the rack, fixed beam, moving beam, the plate device, cylinder and hydraulic system, electric control device components.

Advantage of our pre-press equipment:

1. Working quality to be good, pressing fast and efficient, Easy to operate, reasonable design, stable performance.

2. Fast and efficient pressing, emergency safety braking, trip limited device.

3. The electric system and hydraulic system of the machine have been examined precisely and the free-beam will not fall by its own gravity with results assuring excellent quality.

4. The cylinder is made of super-hard metal,and the seal use low-resistance stepped gaskets, no leakage.

5. Automatic compression and unloading pressure function.

6. Work-table height convenient for human body.

Linyi Ruifeng Machinery Co.,Ltd was founded in 1993, located in Linyi City, Shandong province, the largest wood based panel production base in the world. Through more than 20 years development, Linyi Ruifeng become a modern international enterprise integrating R&D manufacturing and installation together. Now our main products including: automatic particle board production line, automatic MDF production line, automatic OSB production line, semi-automatic plywood production line, semi-automatic finger joint production line, LVL production line and automatic short cycle laminating hot press line and machines related.

Through more than 20 years hard working, the products of LINYI RUIFENG have been widely accepted by domestic market and international market, in every province of China, you can find the factories adopting Linyi Ruifeng’s machinery. And in more than 40 countries, you can find the production lines and machines made by our company.

What is in need by customers is the direction we move toward, strict quality control system is our responsibility for all of our customers. Ruifeng people will insist on the principle of ‘Customer First, Quality first’ to provide more stable and higher efficient products and better service to our customers.

Presale service

Presale service

Ⅰ.Make reliable pratical mechine list and production proposal free of charge, according to customers' actual situation

Ⅱ.Design the machine free of charge, according to customer's production line and production cost,

Ⅲ. Make the workshop and production line layout free of charge, according to customers' factory land

Medium-sales service

Ⅰ.Video for the manufacturing process as customers requirement

Ⅱ.Machine modifying according customers' suggestion

Ⅲ.Order the shipment and prepare the documents for customers' clearance, according to customers' custom requirement

After-sale services

Ⅰ.One year warranty for main machine, cost price for vunerable parts

Ⅱ.Experienced engineer is avaiable for the machine installation and worker training

Ⅲ.Cooperate with Aliyun OS, remote control of trouble shoting and system upgrading

Package:The normal package for machine is containers,nude package,but the spare parts is wooden box.If export to European countries,we will use PE film for packing it or according to your requests.

Shipping :We will ship the products in 30 days after payment.

1. Q:A FACTORY OR A DEALERS?

A:We are a factory who have been producing wood based panel machinery for 25 years.

2. Q:QUALITY CONTROL?

A: Each machine will be tested three times before delivery.

3. Q:DELIVERY TIME?

A: 30-90 days upon receiving deposit.

4. Q:Factory Layout Design?

A:We have engineer team to make layout drawing for customers for free.

5. Q: After-sales Service?

A: We have technician team to help customers on installation.

6. Q:WARRANTY?

A: One-year warranty,and we supply parts and service all the time.

7. Q:PAYMENT TERMS?

A: T/T, L/C are accepted.

8. Q:MOQ?

A: The MOQ is 1 set.

9. Q: How to go to your factory?

A: There’s three flights per day from SHANGHAI, one flights per day from GUANGZHOU. It takes 45 mins from airport(LINYI AIRPORT) to our factory.

Похожие товары

Furniture Door Vacuum Membrane Press Woodworking Machine

Продукт на заказ, полировка пластин SUS

Машина для горячего прессования пресс машина плита

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com