Пресс для брикетирования древесного угля с высокой эффективностью и низким

- Категория: Biomass Briquette Machines >>>

- Поставщик: Gongyi,Xiaoyi,Hongji,Machinery,Factory

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.42 $* | 0.52 $* |

| Aug-15-2025 | 0.20 $* | 0.95 $* |

| Jul-15-2025 | 0.21 $* | 0.92 $* |

| Jun-15-2025 | 0.13 $* | 0.14 $* |

| May-15-2025 | 0.3 $* | 0.49 $* |

| Apr-15-2025 | 0.48 $* | 0.63 $* |

| Mar-15-2025 | 0.74 $* | 0.3 $* |

| Feb-15-2025 | 0.7 $* | 0.47 $* |

| Jan-15-2025 | 0.49 $* | 0.65 $* |

Характеристики

300kg per h wood sawdust/bamboo charcaol briquette machine

introduction of biomass briquette machine:

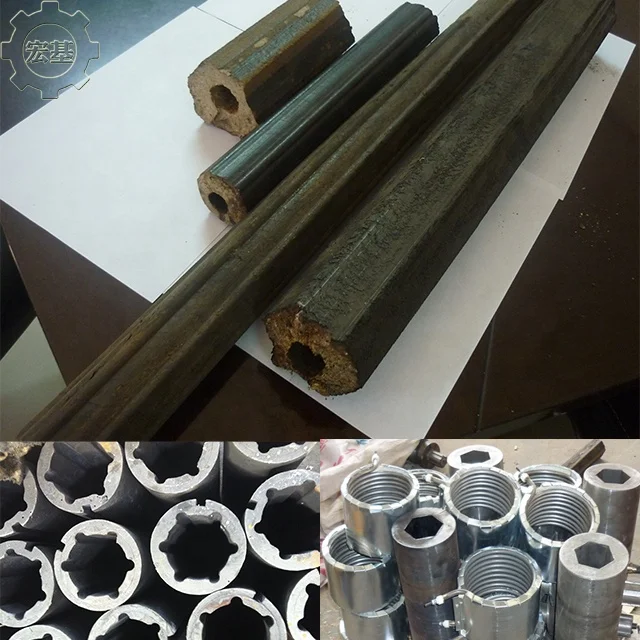

Biomass Sawdust Briquette Machine can make stick shape wood briquette of different diameter and different shape from agro-forest wasted.

This machine can take sawdust, wood, rice husk, coconut shell & other woody material into briquette, which can be used in boiler, heating& warming. After carbonization, the briquette will become charcoal, used in BBQ.

Working Principle of wood Briquette Machine:

1.Briquette machine uses a large screw to grind, compress and extrude the wood into briquettes.

2.The natural lignin content in biomass is liberated with wood fiber under high pressure and temperature.

3.In the briquette machine working process.lignin serves as the glue and combines the particles of wood together,thus binding, compressing the biomass to form into various moulds of high density briquette,such ashexagonal,quadrangular, square,etc.

4.As your requirement, we can also change the briquette shape. And the diameter of briquettes are from 30-90 mm. Moreover non-binder needs to be used during briquette machine working process.

Parameters of biomass briquette machine:

diesel engine wood briquette machine:

| Model | ZBJ-ID | ZBJ-IID | |

| Output( kg/h) | 120-150kg | 250-350kg | |

| Diesel Engine(HP) | 22HP | 30HP | |

| Net/Gross Weight(kg) | 540/590kg | 1080/1180kg | |

| Overall dimension(m) | 1.8X0.76X1.29 | 2.02X0.87X1.5 | |

| Diameter: of finished products (mm) | 30,40, 50mm | 60,70,80,90mm | |

electric engine

| Model | ZBJ-1 | ZBJ-2 | ZBJ-3 | |

| Output(kg/h) | 120-150 | 120-150 | 250-300 | |

| Motor power(kw) | 15 | 11 | 22 | |

| Net/gross Weight(kg) | 540/590 | 650/700 | 1080/1180 | |

| Diameter of | 30,40,50 | 30,40,50 | 60,70,80,90 | |

| briquette(mm) | ||||

| Packing dimension(mm) | 1800*760*1290 | 1800*760*1290 | 2020*870*1500 | |

Features: The extruded wood briquette machine can be used as fuel for briquette boilers or boilers for heating.

(1) NO binder needed during production to make clean & green fuel briquette.

(2) Quantity of heat of final product is 500-1000Kcal higher than raw material.

(3) Can replace firewood and liquefaction gas, with less investment.

(4) Small cubage and easy for transport.

1. Raw Material could be: Sawdust, tree branches, bamboo sawdust, coconut shells, straw, rice husks, corn cobs, peanut skins, vinasse and etc. our briquette machines are capable of making various sizes of charcoal, which can be used for animal food, biomass straw fuel and other related products.

2. Material requirement: Moisture: 8-12%; Size: ≤ 5*5 mm.This machine can be operated 16 hours per day

3. Final briquette is ideal green fuel for use in furnaces, boilers and open fires.

4. Different shape of finished briquettes : Hexagon shape, diamater 50-80MM with a hole inside, the hole's diameter is 15MM, length of final briquettes can be controlled and adjusted between 300MM to 700MM.

We have been adhering “honest first,quality for survival”,as the guideline since we founded company 30 years ago.

we always adhere to customer-centric,and concentrate on improving our product quality continually.

Our company built up with strict quality assurance system and constantly improve customer service system,which promote the quality of pre-sales and after-sales service.

we will try our best to make maximize profits for customers,by perfect equipment & spare supply and timely after-sales service.

We hereby promise:

We always provide reliable products,perfect sales service and strong technical support for you.

1.Pre-sale services:

Act as a good adviser and assistant of customers;help them to get rich and generous returns on their investments.

(1)Introduce company product in details and select appropriate equipment model for customers,according to the scale of their’s factory.

(2)Free site planning,Design and manufacture products depend on customers’ special requirement;

(3)Provide essential technical support, including project design,personnel training, relevant technical documents, etc

2.During the sales services:

Respect customers;devote ourselves to improving the total value of customers.

(1)The product is 100% full inspection before delivery and ensure the product is qualified.

(2)Help customer consultation determine to draft solving plans and other needed convenience help.

3.After-sales services:

Provide considerate service to minimize customers’ worries.

(1)Provide free installation, debugging and technical training, till ensure that customer can operate the equipment alone.

(2)One year warranty, free maintenance (except for man-made causes of failure)

(3)Provide spare parts and maintenance services lifelong (paid services) and continue to provide the necessary technical support