Фильтрующий пресс для очистки сточных вод машина обезвоживания

- Категория: Фильтр-прессовое оборудование >>>

- Поставщик: Shandong,Xuridong,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.8 $* | 0.65 $* |

| Aug-18-2025 | 0.34 $* | 0.45 $* |

| Jul-18-2025 | 0.58 $* | 0.88 $* |

| Jun-18-2025 | 0.78 $* | 0.45 $* |

| May-18-2025 | 0.90 $* | 0.24 $* |

| Apr-18-2025 | 0.68 $* | 0.88 $* |

| Mar-18-2025 | 0.16 $* | 0.54 $* |

| Feb-18-2025 | 0.23 $* | 0.72 $* |

| Jan-18-2025 | 0.95 $* | 0.59 $* |

Характеристики

wastewater treatment belt filter press for sludge dewatering machine

Function & application

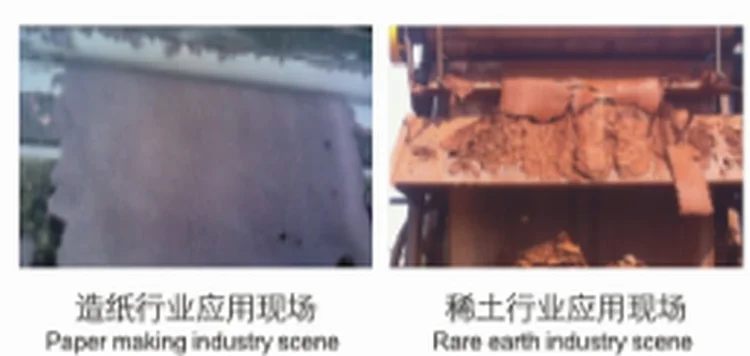

The belt filter (sometimes called a belt press filter, or belt filter press) is an industrial machine, used for solid/liquid separation processes, particularly the dewatering of sludge in the chemical industry, mining, food processing and water treatment. The process of filtration is primarily obtained by passing a pair of filtering belts through a system of rollers. The system takes a sludge as a feed, and separates it into a filtrate and a solid cake.

As a part in waste water treatment system, it is used for dewatering of suspended particles and residue after treated so as to avoid secondary pollution.

It is also applicable for treatment of thickener concentration and black liquor extraction,including municipal sewage, textile printing and dyeing, electroplating, papermaking, leather, brewing, food processing, coal washing, petrochemical, chemical, metallurgical, pharmaceutical, ceramic and other industries sludge dewatering treatment.

Feature & benefit

1. Large treating capacity

2. Low energy consumption and low cost

3. Unique tilt and long wedge area ensures stable performance

4. Long gravity dewatering area with strong treating capacity, heavy load capacity, low energy consumption and low cost.

5. Unique tilt and long wedge area ensures stable performance.

6. Multi-roller decreasing dia. is compact in configuration and improves solid-content of filter cake.

7. New auto-adjusting and tilting system greatly improves life time of filter belt.

8. Adopts two independent backwash systems.

Technical specification

Item | Model | |||||||

ZDYA-500 | ZDYA-700 | ZDYA-1000 | ZDYA-1500 | ZDYA-2000 | ZDYA-2500 | ZDYA-3000 | ZDYA-4000 | |

Main engine Power(kw) | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 4 | 5.5 | 7.5 |

Air compressor(kw) | 1.1 | 2.2 | 2.2 | 3 | 4 | 5.5 | 5.5 | 7.5 |

Belt width (mm) | 500 | 700 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 |

Capacity (m3/h) | 0.5~4 | 4~6 | 5~7 | 8~10 | 12~15 | 15~18 | 18~25 | 25~30 |

Overall dimension | Length(mm) | 4920 | 4920 | 4920 | 4920 | 4920 | 4920 | 4920 |

Width(mm) | 978 | 1178 | 1478 | 1978 | 2478 | 2978 | 3478 | |

Height(mm) | 2350 | 2350 | 2350 | 2350 | 2350 | 2350 | 2350 | |

Feeding concentration | 3-8% | |||||||

Discharge concentration | 25-40% | |||||||

01. We are a manufacturer and we have import and export rights.

02. We produce wonderful environmental protection machines and solutions, pulp and paper making machines and solutions as well as tissue paper converting machinery and solutions,

03. Our main manufacturing facility which spans nearly 30,000m2.

04. We have achieved a total of 32 patents over the past few years.

05. Each year the output value of our products can reach up to 150 million RMB, to domestic and overseas.

06. We are in very close proximity to a very famous port city – Qingdao in northern China, and this location provides us with a plethora of logistics advantages, including: easy and cost effective transport by both air and sea, also.

01. Detailed installation manual and maintenance guideline are provided with the equipment.

02. Technical training and site-commissioning are available for you.

03.Any equipment issue, we will stand by. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

01. How to buy your idea products?

A: You can provide us your water sources, water quality, flow rate and ground area (connect us for more details).

02. How to pay?

A: TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, 70% balance before loading by TT.

03. What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 4 to 6 weeks.

04. How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

05. How to keep your equipments from corrosion?

A: We use the world-famous paint, like SigmaCoatings, PainBow, etc. What's more, we paint strictly according to the standard process.

06. How do you manufacture your equipment ?

A: Our machining technology includes laser/plasma cutting, automatic welding, CNC cutting and bending.

07. How to install after the equipment arriving destination?

A: We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation,