Машины для формовки металлических гвоздиков и гусеничных валков Из

- Категория: Metal Building Materials >>>

- Поставщик: Cangzhou,Zhiye,Cold,Forming,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.27 $* | 0.49 $* |

| Aug-19-2025 | 0.29 $* | 0.22 $* |

| Jul-19-2025 | 0.25 $* | 0.68 $* |

| Jun-19-2025 | 0.27 $* | 0.9 $* |

| May-19-2025 | 0.82 $* | 0.79 $* |

| Apr-19-2025 | 0.35 $* | 0.46 $* |

| Mar-19-2025 | 0.14 $* | 0.54 $* |

| Feb-19-2025 | 0.40 $* | 0.61 $* |

| Jan-19-2025 | 0.40 $* | 0.67 $* |

Характеристики

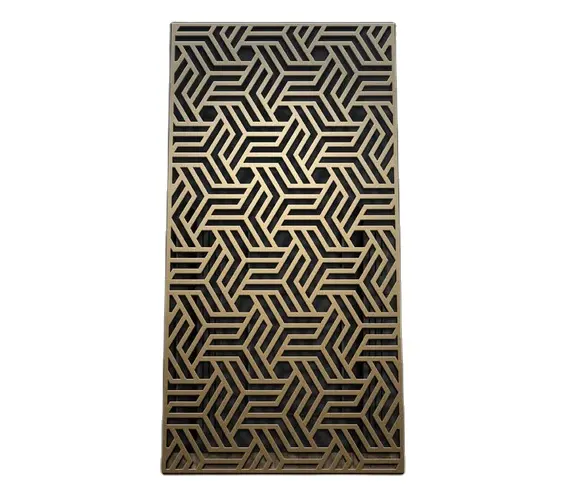

Products made by this machine is easy to install, used together with different colors can make it appear dye-in-the-wood individual character. Width of 75, 100, 150, 200, and 300 T-shaped keel can be assembled arbitrarily, and they are connected tightly. They can be fixed on the device which is specially used for keels, they can tear down individually.

Products made by this machine are suitable to use as building decorations, especially suitable to use in bedroom, kitchen, washroom, corridor and so on.Material for this machine is galvanized steel plate, snowflake plate and colored steel plate.

Technical parameter of product line:

1. Applied plank stuff: color armor plate

2. Applied slab thickness: 0.3-1.0mm

3. Charge in width: 1000mm

4. Line speed: 0-14m/min

5. Rolling rows: 16rows

6. Rolling diameter: 70mm

7. Dimensions: 8.5m*1.5m*1.6m

8. Weight: 5t

9. Power: 4kw+4kw

Equipment parts:

1. Steel strip supporting frame

2. Feeding platform

3. Automatic shearing system

4. Hydraulic system

5. Steel strip unfolding system

6. Computer control system

7. High-precision automatic counter

8. Receiving table

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

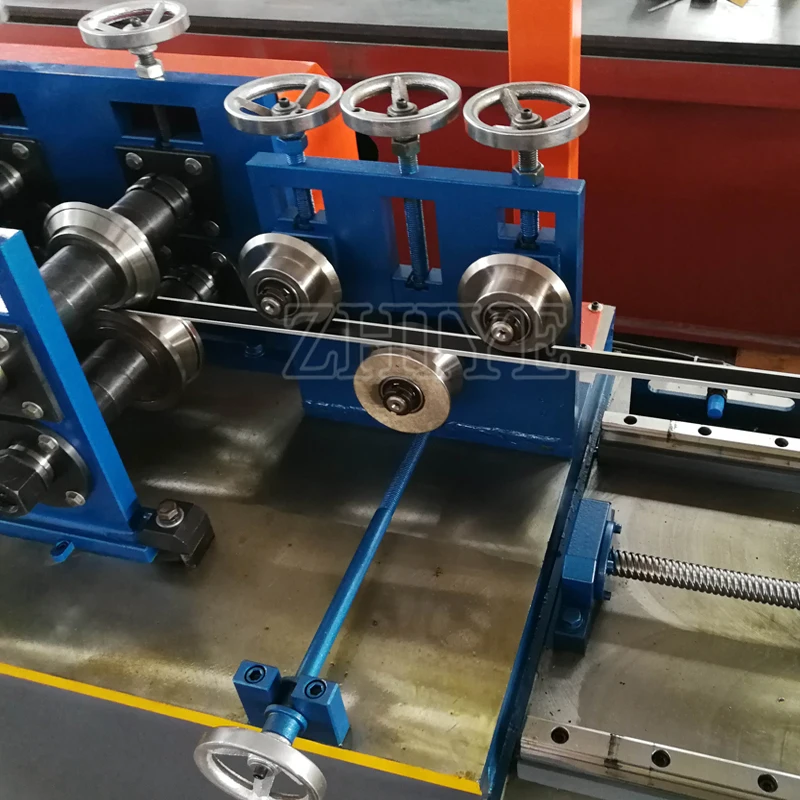

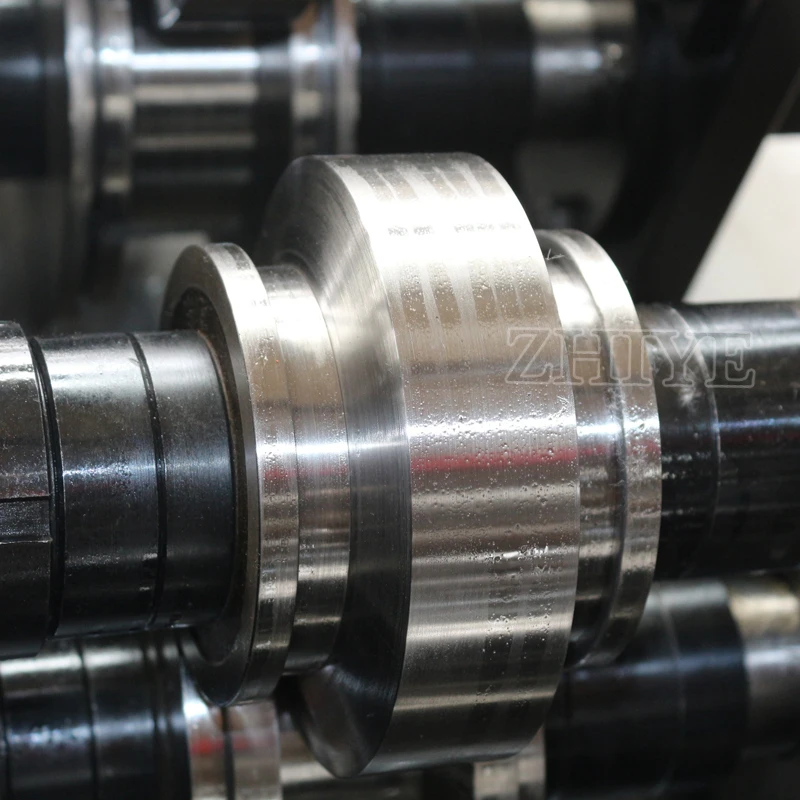

Main Roll Forming Machine

It is designed according to the customers' profile drawing. It adopts motor reducer drive, chain transmission, roller surfaces polishing, hard plating, heat treatment and galvanization treatment. The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Cutting Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12

Computer Control Cabinet

It adopts Delta/Siemens PLC to control. The target piece's length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

Cangzhou Zhiye Cold Forming Machinery Co.,Ltd has been entitled with the "key private enterprise" by the local government and over the years, we have been dedicated to the research&development as well as the fabrication of the forming machines of metallic plate cold bending roller.

Our company is situated alongside the 104 national Road in Cangzhou, Botou City, which has been praised as the "famous casting cities" in china. It covers an area of more than 30000 square meters and in which, nearly one hundred staff are professional talents in relevant domains. Our main products are: roofing wall panel roll forming machines, tile roll forming machines,C/U/Z purlin roll forming machines,floor decking roll forming machines, steel frame truss roll forming machines,pipe roll forming machines. We can customize the design and fabrication on the particular type of machine and responsible for the fully implementation of the post service, including the technical instruction, production, installment, debugging, maintenance and so on.

We have put forward a newly developed hi-tech product-KDQ type of measured cutting control system, which has integrated the measurement, monitoring fore-warning systems together and featuring on the high starting point, precise measurement, user-friendly and comprehensive monitoring.

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

Roll Forming Machine

100% Response Rate

Roll Forming Machine

100% Response Rate

Roll Forming Machine

100% Response Rate