Малая линия по производству картофеля фри машина для производства картофельных чипсов переработке

- Категория: Фаст машины >>>

- Поставщик: Zhengzhou,Taizy,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-17-2025 | 1682551.35 $* | 1716202.10 $* |

| Jul-17-2025 | 1364588.21 $* | 1391880.49 $* |

| Jun-17-2025 | 1656054.99 $* | 1689175.74 $* |

| May-17-2025 | 1642805.4 $* | 1675661.95 $* |

| Apr-17-2025 | 1311595.26 $* | 1337827.66 $* |

| Mar-17-2025 | 1616308.69 $* | 1648634.18 $* |

| Feb-17-2025 | 1603060.26 $* | 1635121.49 $* |

| Jan-17-2025 | 1589812.23 $* | 1621608.81 $* |

Характеристики

Product Description of small scale french fries production line Potato Chips Maker

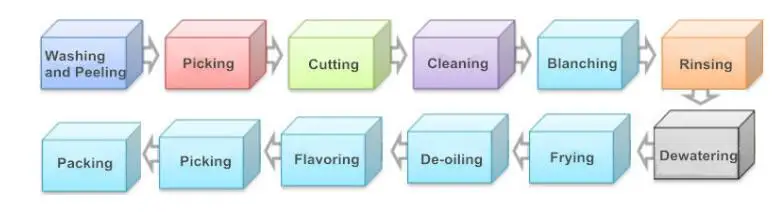

Complete sets of equipment for processing potato chips and chips include: cleaning and peeling machine, potato chip cutting machine, blanching machine, dehydrator, frying machine, oil stripper, seasoning machine, packaging machine.

Suitable for medium and small food processing enterprises, widely used in hotels, hotels, Fried chicken restaurants, fast-food restaurants, hostels, troops, universities, enterprise canteens, Fried food enterprises and chain stores, etc.The deoiling and deoiling machine is installed with anti-vibration system. The equipment will not vibrate during deoiling and deoiling.

Introduction of complete equipment

1. Cleaning and peeling machine: the cleaning and peeling machine with gold steel sand lining or brush type can finish the cleaning and peeling work at the same time.High efficiency and low loss.

2. Chip cutting machine: it can be sliced and sliced.The thickness of slice and the size of sliver can be adjusted at will.

3. Blanching machine: rinse and protect the cut potato chips (strips).

4. Dehydrator: use centrifugal force to dehydrate.Dehydration before frying can greatly shorten the frying time and improve the taste of crisps.Improve production efficiency and reduce production cost.

5. Frying machine: this type of frying equipment.As the proportion of water and oil is different, the water is on the bottom, and the oil is heated on the top to make potato chips. The residue is directly deposited in the water, and the oil does not emit black smoke, which greatly extends the oil service cycle and greatly reduces the cost.The oil temperature controls precisely, thus ensuring the quality and taste of potato chips.When the work is done, water is released and the residue flows out with the water.

6. Deoiling machine: centrifugal deoiling machine takes off the freshly Fried potato chips (strips), overcoming the defects of high oil content and greasy mouth of potato chips (strips).Improved the texture of potato chips.

7. Seasoning machine: the roller seasoning machine is made of stainless steel.The potato chips (strips) are rolled evenly in the rotation of the roller, and seasoning is added with sprinkling or spray.Uniform seasoning is not easy to crumble.

8. Packaging machine: nitrogen is added into the packaging bag during packaging, which can effectively prevent the chips (strips) from being broken and prolong the shelf life.Inflating, packing and marking are completed once.

Parameter of small scale french fries production line Potato Chips Maker

Semi-automatic:

| model | power | weight | capacity |

| TZ-30 | 58kw | 1400kg | 30kg/h |

| TZ-50 | 62kw | 1600kg | 50kg/h |

| TZ-70 | 68kw | 1700kg | 70kg/h |

| TZ-100 | 72kw | 2000kg | 100kg/h |

Automatic:

| model | power | weight | capacity |

| TZ-200 | 128kw | 5500kg | 200kg/h |

| TZ-300 | 132kw | 6000kg | 300kg/h |

| TZ-500 | 160kw | 7000kg | 500kg/h |

| TZ-1000 | 210kw | 10000kg | 1000kg/h |

| TZ-2000 | 300kw | 15000kg | 2000kg/h |

Picture show of small scale french fries production line Potato Chips Maker

Semi-automatic:

Automatic:

Zhengzhou Taizy machinery Co. Ltd. is a professional company in design and research, manufacturing, sales and service for a variety of food machines, including large and medium sized kitchen special equipment, fruit and vegetable processing equipment, meat processing equipment, snack food equipment, fresh-keeping refrigeration equipment, soy products equipment, food packaging equipment and other related machines. Our company's machines are sold to Southeast Asia, UK, Germany, France, Italy, Netherlands, Russia, South Africa, Brazil, Canada, USA, Australia, New Zealand, Mozambique, Zambia, Ghana, Pakistan, Spain, Kazakhstan, India, Japan, Korea, United Arab Emirates, and more than 100 countries and regions

We provide technology consultation.

We provide details design of your factory.

We supply spare parts for long time.

We provide 24-hour service.

Q: What capacity does the french fries production line have?

A: Our factory offers fully automatic and semi-automatic production lines for large, medium and small factories.

Q: How much is the water temperature when blanching potato chips?

A: Blanching temperature is 80 ° C, blanching time is about 1-2 minutes.

Q: How many degrees does the oil temperature set when frying French fries?

A: Frying time is about 5-6min, frying temperature is 160-180°C.

Q: How do I know about the details and quality of your machine?

A: First, we have product brochures covering all details including parameter, material, output, etc. of most of our production lines; secondly, we can provide you with videos filmed on-site with details about the working process and how mechanical parts work during operation; at last, you are warmly welcomed for on-site inspection at our factories.

Q: What certification do you have?

A: We have CE, BV, SGS, ISO, CCC, etc. Please do trust us, we are determined to provide you the best quality equipment.