SBM низкая цена серия LM вертикальная роликовая мельница в цементной

- Категория: Mine Mill >>>

- Поставщик: Shibang,Industry,&,Technology,Group,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 10577.36 $* | 11106.22 $* |

| Aug-15-2025 | 10488.10 $* | 11012.67 $* |

| Jul-15-2025 | 8799.79 $* | 9239.45 $* |

| Jun-15-2025 | 10310.89 $* | 10826.13 $* |

| May-15-2025 | 8977.4 $* | 9426.11 $* |

| Apr-15-2025 | 10132.98 $* | 10639.64 $* |

| Mar-15-2025 | 10043.40 $* | 10545.35 $* |

| Feb-15-2025 | 9955.22 $* | 10453.21 $* |

| Jan-15-2025 | 9866.64 $* | 10359.90 $* |

Характеристики

> Introduction

Development History

Established in 1987, SBM has had 30 years of experience in mining machine industry. So far, SBM has complete R&D, production, sales and service system, becoming a distinguished manufacturer in Chinese mining machine industry and competing with global famous enterprises.

SBM low price LM series vertical roller mill in cement industry price

Applicable material | Barite, basalt, bentonite, calcite, calcium carbonate, coal, dolomite, feldspar, granite, gravel, gypsum, micro silica, pebble, quartz, slag and so on |

Capacity(t/h) | 4-300TPH |

Feeding Size (mm) | < 70 mm |

Model Number | LM80K, LM110K, LM130K ,LM150K and so on |

LM vertical roller mill in cement industry price

Based on the absorption of advanced technologies of famous international corporations and 30 years’ experience in grinding mill production, SBM has launched the LM vertical roller mill in cement industry price which integrates five functions of crushing, grinding, powder selection, drying and material conveying. It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protection.

Input Size: 0-70mm

Capacity: 4-300TPH

Material: Limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

Quick Quotation!Recommend suitable models and provide free design solutions.

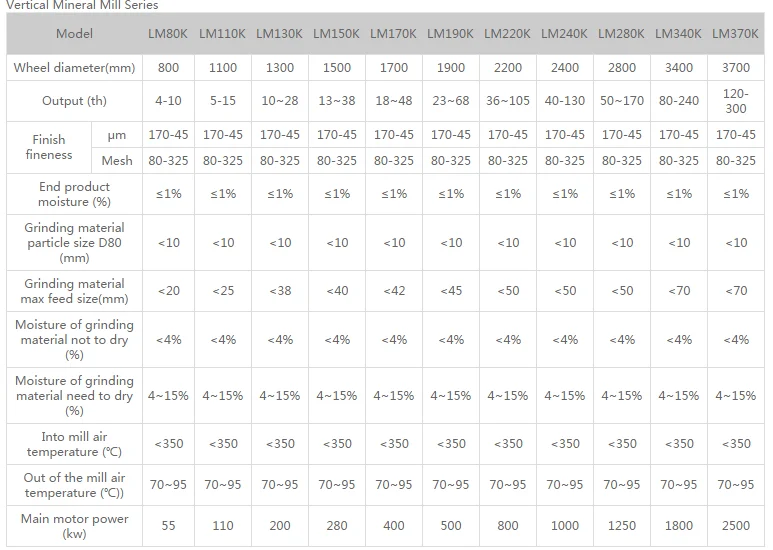

> Technical data:

SBM low price LM series vertical roller mill in cement industry price

> Advantage:

SBM low price LM series vertical roller mill in cement industry price

- Less Comprehensive Investment

LM vertical roller mill in cement industry price integrates crushing, drying, grinding, separating and transport. The structure is simple while the layout is compact. Its occupational area is about 50% of that of the ball-milling system. The LM grinding mill can also be arranged outdoors, which greatly reduces the investment cost.

Comprehensive Optimization, Lower Operating Costs

From aspects of grinding efficiency, powder drying, abrasion of vulnerable parts and maintenance & replacement of spare parts, SBM’s LM Vertical Grinding Mill achieves lower energy consumption, stronger drying capacity, as well as lower abrasion and easier checks of core parts, saving the operating costs greatly.

Short Grinding Time & Low Iron Content

The materials linger in the grinding mill for a short time, which can reduce repeated grinding and is easy to detect and control the grain size and chemical component of the product. In addition, the grinding roller and millstone do not contact directly. The iron content in the product is very low, and the iron generated due to mechanical wear is easy to be removed, thus effectively guaranteeing the whiteness and purity of the material.

Greener & More Automated

The operation of LM grinding mill is stable and has small vibration, so that the noise is small. The system is sealed in an integral manner and works under negative pressure, so that there is no dust spilling and the environment can keep clean with the emission standard far better than the international standard. LM grinding mill is also equipped with expert-level automatic control system, which can realize free switch between remote control and local control. The operations are simple and labor-saving.

Digitalized Processing, Higher Precision

There are tens of lines of numerical controlling machine tools. Operations such as steel plates’ cutting, bending, planing, milling and paint spraying are all controlled numerically. The machining precision is high, especially for the core parts.

Sufficient Supply Of Spare Parts, Worry-Free Operation

SBM, whose businesses cover production and sales, takes responsibility for every machine produced by ourselves. We can offer customers technical services about products and original spare parts to ensure the worry-free operation.

> working principle:

SBM low price LM series vertical roller mill in cement industry price

The grinding plate rotates under the action of main motor of LM vertical roller mill in cement industry price and the reducer. Meanwhile, hot wind enters the vertical mill. After raw materials fall onto the center of grinding plate, they move to the edge of grinding plate under the action of centrifugal force. While passing through the grinding area between roller and grinding plate, bulky materials are broken directly by the pressure of roller while fine materials form a layer where materials crush each other. Broken materials after grinding continue moving to the edge of grinding plate until they are brought away by the airflow at the air ring. For coarse materials which cannot be brought away would fall onto the grinding plate for another grinding. When passing the upper separator, materials in the air flow will be divided into two parts by the blades of rotor, that is, coarse particles and fine powders. Coarse particles would be sent back to have another grinding while the qualified fine powders enter the powder collector with airflow as finished products. For sundries like iron block in materials, when they move to the fringe of grinding plate, because of their heavier weight, they would drop to the lower cavity of grinding mill and next be sent into the discharging port by scarper installed at the bottom of grinding plate and finally be discharged out of the grinding mill.

Jiangsu 100,000TPY Limestone Grinding Line

The customer company is mainly engaged in limestone powder preparation. The finished powders would be supplied to citric acid industry. This time, the customer bought 2 complete sets of MTW175 European Grinding Mills from SBM to grind limestone.

Daily Operation: 24h Material: Limestone Input Size: 0-35mm Output Size: 250-325mesh

Customer Feedback

SBM was very concerned about our usage status. It's rare and commendable that SBM could make continuous improvements according to our actual operation situations. So, undoubtedly, the output of this MTW175 European Grinding Mill made us satisfied. Compared with former machines we used, SBM's machines were easier to operate and maintain. Now, our company intends to expand our production scale. If there is any need for machines, we would choose SBM once more without hesitation.

Manager Lin, head of the company

Welcome to visit our factory

See what other customers say

- “We haven’t replaced any spare part after continuous running for 16 months. Everything is still in perfect condition so far !”-- Mrs. Camille Camille,concrete crushing plant

- "Our local stones market is good, so I value the stability of the equipment operation. The quality of the equipment is good, and maintenance operation is convenient, basically do not need the company here to send technicians, we follow the manual can complete. The output is also fully achieved, the profit is good, a few of my colleagues visited here after I also ordered the world state equipment. " -- Mr. Chen, the sand production line

- " I am pleased with the company's design process and the wiring, many of the nearby counterparts to watch the production line. Equipment quality is also satisfactory, the company's service is good, we can not meet the problem, will soon be able to send engineers over guidance. Within the original plan to recover the cost within two years, it seems that about a year now is enough. " -- Mr.Fernanda Luisa, the mobile stone production line

- " SBM help me build the crushing production line, equipment selection is more advanced, scientific and reasonable, high intelligent control, more peace of mind. So far, the daily profit of nearly 100000 yuan, I am very satisfied. " -- Mr. Susan James , the limestone grinding plant

| After-sales service | we will contact the professional group that responsible for ship bookings, commodity inspection, commercial invoices, packing list, insurance policy and so on |

| Warranty period | 12 months |

| Trade Assurance | We have joined Alibaba trust system, please rest assured |

| Foreign agent | SBM has established offices in more than 20 countrie |

| language | Any national language |

| Type of shipping | Ocean Shipping |

| Packing | Container packaging |

| The machine is broken | our rigorous installed engineers also will do some certain installation debugging training, etc. |

| Recovery rate | 24 hours a day and 7 days a week services |

| Visit factory | welcome to visit at any time |

| Parts | We can supply spare parts at any time |

Shipping

1."small parts are wooden box package"

2."the major machine nude packing, container, or upon customers' requirement"

3."export standard"

4. Delivery Time: 30 days for batch goods.

Payment Terms

1. Payment: T/T, L/C

2. MOQ: 1set

3. Warranty : 1 years

Shibang Industry & Technology Group Co., Ltd.

Development History

Established in 1987, SBM has had 30 years of experience in mining machine industry. So far, SBM has complete R&D, production, sales and service system, becoming a distinguished manufacturer in Chinese mining machine industry and competing with global famous enterprises.

Inquiry about Service Outlets

SBM's marketing network presently has reached more than 160 countries and regions in Asia, Africa, Europe, Americas, and Oceania. SBM has established offices in more than 20 countries. Through the marketing network and overseas offices, SBM is in close contact with global users thus providing them with more timely and considerate services.

Overseas Offices

The establishment of overseas offices reflects implementation of SBM's strategy of "rapid services through localization". If having any questions, local customers may contact the nearest SBM office even it is located in a neighboring country or region. SBM will solve their difficulties as quickly as possible.

Spare Parts Supply

To deliver spare parts to customer's production sites as fast as possible, SBM has built spare parts warehouses. On receiving customer's call, we take spare parts from the warehouse in the shortest time possible to reduce customer's awaiting time and risk of equipment outage.

Now, leave a message and we'll contact you right away !!!

↓↓↓

Please enter your demand such as Raw material type, Capacity, Feeding material size, Final product size, etc. To become our quality clients will have access to a discount of contract!

Please contact us by any ways! We quickly give the right models and prices.

CONTACT US

Shibang Industry & Technology Group Co., Ltd.

Add. No.416 Jianye Road, South Jinqiao Area, Pudong New Area, Shanghai, China.