4x8 футов 3D машина для резьбы по дереву с ЧПУ 1325 деревообрабатывающие

- Категория: Станок по дереву >>>

- Поставщик: Jinan,Hitec,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 4165.17 $* | 4373.57 $* |

| Aug-16-2025 | 4130.61 $* | 4337.81 $* |

| Jul-16-2025 | 3465.58 $* | 3638.92 $* |

| Jun-16-2025 | 4060.23 $* | 4263.36 $* |

| May-16-2025 | 3535.70 $* | 3712.79 $* |

| Apr-16-2025 | 3990.25 $* | 4190.18 $* |

| Mar-16-2025 | 3955.15 $* | 4153.62 $* |

| Feb-16-2025 | 3920.23 $* | 4116.0 $* |

| Jan-16-2025 | 3885.92 $* | 4079.1 $* |

Характеристики

1325 Woodworking Cnc Router Application

1.Furniture industry :To engrave versitile patterns on Solid wooden door, Composite door, Cabinet door, Sofa legs, bedside board, classical furniture and kinds of board furniture.

2. Decoration Industry :Decorating kinds of patterns for wall fresco, folding screen, cubic wave board, acoustic board.

3. Musical instrument :Shaping the guitar, piano, and other instruments, and the embossing on the surface of the instruments.

4. Mould industry :Precision founding the wooden mould, founding foam, food mould, etc.

5. Arts and Crafts industry :To process kind of embossing, shadow engraving, pendant,car Accessories and so on.

6. Advertising industry : Acrylic cutting, engraving, sign making.

Description | Parameter |

X,Y,Z Working Area | 1300x2500x200mm (option 1500x3000mm 2000x3000mm 2000x4000mm) |

Table Size | 1530×3040mm |

X,Y,Z Traveling Positioning Accuracy | ±0.03/300mm |

X,Y,Z Repositioning Accuracy | ±0.03mm |

Table Surface | Vacuum table (option T slot table) |

Frame | Welded Structure |

X, Y Structure | Helical Rack and Pinion Drive, |

Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

Max. Power Consumption | (Without Spindle) 3.5Kw |

Max. Rapid Travel Rate | 33000mm/min |

Max. Working Speed | 25000mm/min |

Spindle Power | 3.5KW |

Spindle Speed | 0-18000RPM(air cooling) |

Drive Motors | Stepper Motor System |

Working Voltage | AC380V/220V |

Command Language | G Code |

1325 Woodworking Cnc Router Main Features

We offer cnc wood router,cnc laser,cnc plasma,cnc parts.

3. Put wooden boards on the table to prevent the table from being attrited. The accessories are fixed on the wooden boards of the machine with packing straps to prevent the accessories from moving.

4. The anti-rust film bag is put on the machine to prevent rust, water and scratched. The plastic film is wrapped around the

anti-rust film bag for reinforcement.

5. Then pack it in a fumigation free plywood box.

6. Finally fix the wooden box with steel belt.

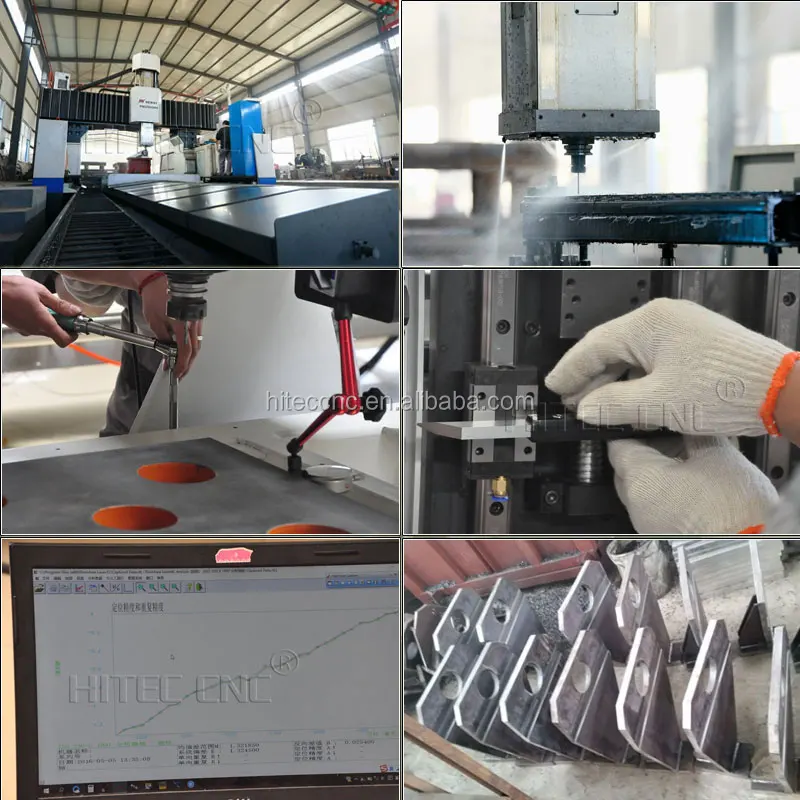

All the machine parts Assembe by our machine milling and lathe machine,can be guarantee the machine precision and fast delivery time

We welcome all our buyers come to visit our factory for directly free training, our professional engineer will support you to study the machine operation.

We will supply machine operation manual, training videos and machine parameters, our engineer will supply online machine installation and training.

The customers’ technicians can keep in touch with our engineer at any time, through wechat/whatsapp/mobile phone or email, our engineer will help to solve your problems as soon as possible.

If customer need, we will send our engineer to the customers’ place to provide install and train the customer to use the

machine,our engineer will stay at customers’ place for 5-7days,customers should pay the round-trip airkets/hotels/food for our engineer.

our products can meet the needs of users to the greatest extent, and at the same time make the customer's investment play the

largest comprehensive economic benefit.

user's reasonable temporary needs;

3. Collaborate friendly with users to deliver qualified products.

Except the damage is artificial, we are responsible for offering the fittings free of charge during the guarantee period, but you

need to send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. Out of

the guaranteed period, should the parts required to be repaired or replaced, if any, the parts will be charged.