Длинный срок службы 18 дюймов K8 труба из чугуна с шаровидным

- Категория: Железные трубы >>>

- Поставщик: Topsun,Pipelines,(Huangshi),Company,Limited

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 93.99 $* | 98.35 $* |

| Aug-16-2025 | 92.93 $* | 97.58 $* |

| Jul-16-2025 | 77.85 $* | 81.4 $* |

| Jun-16-2025 | 90.34 $* | 95.85 $* |

| May-16-2025 | 79.29 $* | 83.83 $* |

| Apr-16-2025 | 89.7 $* | 93.52 $* |

| Mar-16-2025 | 88.81 $* | 92.62 $* |

| Feb-16-2025 | 87.77 $* | 91.21 $* |

| Jan-16-2025 | 87.94 $* | 91.95 $* |

Характеристики

External Coatings

Topsun offers a range of proven external coatings to suit all types of ground conditions, the standard costing is zinalimu, topsun's zinc and aluminum alloy system.

Pipe range

Standard offer, water -class 1

| DN | Prod Code | Prod Code | Pipe ClaTP | Length (mm) | Spigot OD mm (ØDE) | Socket OD mm (ØB) | Weight (Kg/m) | |||||||||

| DN80 | TPA80Q60 | C40 | 6000 | 98 | 167.0 | 12.0 | ||||||||||

| DN100 | TPB10Q60 | C40 | 6000 | 118 | 188.0 | 15.0 | ||||||||||

| DN150 | TPB15Q60 | C40 | 6000 | 170 | 242.0 | 22.0 | ||||||||||

| DN200 | TPB20Q60 | C40 | 6000 | 222 | 295.0 | 30.0 | ||||||||||

| DN250 | TPB25Q60 | C40 | 6000 | 274 | 352.0 | 42.0 | ||||||||||

| DN300 | TPB30F60 | C40 | 6000 | 326 | 409.2 | 55.5 | ||||||||||

| DN350 | TPB35G60 | C30 | 6000 | 378 | 464.2 | 69.0 | ||||||||||

| DN400 | TPB40G60 | C30 | 6000 | 429 | 516.2 | 79.5 | ||||||||||

| DN450 | TPB45G60 | C30 | 6000 | 480 | 574.2 | 94.0 | ||||||||||

| DN500 | TPB50G60 | C30 | 6000 | 532 | 629.2 | 111.0 | ||||||||||

| DN600 | TPB60G60 | C30 | 6000 | 635 | 738.5 | 150.5 | ||||||||||

| DN700 | TPB70H60* | TPB70G70 | C25/C30 | 6000/6960 | 738 | 863.0 | 188.0/217.9 | |||||||||

| DN800 | TPB80H70* | TPB80G70 | C25/C30 | 6950 | 842 | 974.0 | 213.0/267.0 | |||||||||

| DN900 | TPB90H70 | TPB90G70* | C25/C30 | 6950 | 945 | 1082.0 | 260.0/279.0 | |||||||||

| DN1000 | TPC10H70 | TPC10G70* | C25/C30 | 6960 | 1048 | 1191.0 | 311.5/334.0 | |||||||||

| DN1200 | TPC12H80 | C25 | 8190 | 1255 | 1412.5 | 461.5 | ||||||||||

| DN1400 | TPC14H80 | C25 | 8170 | 1462 | 1592.1 | 634.5 | ||||||||||

| DN1600 | TPC16H80 | C25 | 8160 | 1668 | 1815.9 | 807.5 | ||||||||||

| DN1800 | TPC18H80 | C25 | 8150 | 1875 | 2032.2 | 995.0 | ||||||||||

| DN2000 | TPC20H80 | C25 | 8130 | 2082 | 2259.0 | 1210.0 | ||||||||||

Standard offer, water - CLass 2

| DN | Prod Code | Pipe ClaTP | Length (mm) | Spigot OD mm (øDE) | Socket OD mm (øDE) | Weight (Kg/m) | ||||||||||

| DN80 | 189486 | C40 | 5500 | 98 | 167.0 | 15.0 | ||||||||||

| DN100 | 189509 | C40 | 5500 | 118 | 188.0 | 17.5 | ||||||||||

| DN150 | 189515 | C40 | 5500 | 170 | 242.0 | 26.0 | ||||||||||

| DN200 | 197942 | C40 | 5500 | 222 | 295.0 | 35.0 | ||||||||||

| DN250 | 189518 | C40 | 5500 | 274 | 352.0 | 45.5 | ||||||||||

| DN300 | 189519 | C40 | 5500 | 326 | 409.2 | 57.0 | ||||||||||

| DN350 | TPB35G55EC | C30 | 5500 | 378 | 464.2 | 69.0 | ||||||||||

| DN400 | TPB40G55EC | C30 | 5500 | 429 | 516.2 | 79.5 | ||||||||||

| DN450 | TPB45G55EC | C30 | 5500 | 480 | 574.2 | 94.0 | ||||||||||

| DN500 | TPB50G55EC | C30 | 5500 | 532 | 629.2 | 111.0 | ||||||||||

| DN600 | TPB60G55EC | C30 | 5500 | 635 | 738.5 | 150.5 | ||||||||||

| DN700 | TPB70N55EC | C30 | 5500 | 738 | 863.0 | 188.0 | ||||||||||

Standard offer Sewer

| DN | Integral Plus Prod code | Integral Prod code | Length (mm) | Spigot OD mm (øDE | Socket OD mm (øDE) | Weight (Kg/m) | |

| DN80 | 205667 | TPA80S60 | 6000 | 98 | 167.0 | 13.0 | |

| DN100 | 205669 | TPB10S60 | 6000 | 118 | 188.0 | 16.0 | |

| DN150 | 205670 | TPB15S60 | 6000 | 170 | 242.0 | 23.5 | |

| DN200 | 205711 | TPB20S60 | 6000 | 222 | 295.0 | 31.0 | |

| DN250 | 205718 | TPB25S60 | 6000 | 274 | 352.0 | 40.5 | |

| DN300 | 205712 | TPB30S60 | 6000 | 326 | 409.2 | 51.0 | |

| DN350 | 205719 | TPB35S60 | 6000 | 378 | 464.2 | 66.5 | |

| DN400 | 205720 | TPB40S60 | 6000 | 429 | 516.2 | 78.0 | |

| DN450 | 205731 | TPB45S60 | 6000 | 480 | 574.2 | 92.5 | |

| DN500 | 205732 | TPB50S60 | 6000 | 532 | 629.2 | 106.5 | |

| DN600 | 205733 | TPB60S60 | 6000 | 635 | 738.5 | 138.0 | |

| DN700 | 205735 | TPB70E69 | 6000/6950 | 738 | 863.0 | 201.0 | |

| DN800 | 206666 | TPB80E69 | 6950 | 842 | 974.0 | 243.5 | |

| DN900 | TPB90E69 | 6950 | 945 | 1082.0 | 291.5 | ||

| DN1000 | TPC10E69 | 6960 | 1048 | 1191.0 | 343.0 | ||

| DN1200 | TPC12N79 | 8190 | 1255 | 1412.5 | 507.5 | ||

| DN1400 | TPC14N80 | 8170 | 1462 | 1592.1 | 679.0 | ||

| DN1600 | TPC16N80 | 8160 | 1668 | 1815.9 | 851.5 | ||

| DN1800 | TPC18N80 | 8150 | 1875 | 2032.2 | 1036.5 | ||

| DN2000 | TPC20N80 | 8130 | 2082 | 2259.0 | 1242.0 | ||

High strength and stiffness

Ductile iron is suitable for installation in open fields or high traffic load areas and can

be laid at a variety of depths. The high material strength minimises the need for

imported bedding and surround, hence minimising the impact on the environment.

* Can be laid in narrow and/or shallow trenches

*Can be laid at a wide range of depths with no detrimental effect on the

performance of the pipe

* Minimises risk due to unforeseen site hazards, such as second-comer damage

Pressure Capability:

Ductile Iron offers the solution whatever the pressure TopSun pipe systems are designed to give long term

performance whatever the pressure requirements.

*Ductile Iron systems cover a wide spectrum of pressure requirements

*Ability to cope with increases in main pressure requirement

*Simple to specify

Topsun supplies pipe for potable water and sewerage applications in diameter

range DN80-2000, all topsun pipes are manufactured in accordance with the

latest version of BS EN545 for potable water and BS EN598 for wewerage

our goal

To generate a high standard of commitment to our customers

To treat our clients, suppliers and employees with honesty and respect

To growth in both business and personal life

To provide a fabulous working environment with advanced technology that enhance all

employees essential of life

To offer an unsurpassed level of service at the most competitive rates

To produce and deliver the finest quality water and wastewater pipe material in the world, Ductile Iron Pipe.

Our Logistics department will offer:

Superior customer service

Better relationships

Enhanced efficiency

What is the difference between Thickness Class and Pressure Class Ductile Iron Pipe?

The basic difference is a change in terminology in how Ductile Iron is classified under the specifications. The design and manufacturing requirements have not changed since 1976. The difference between the two is the thickness classes have no particular meaning, while the pressure classes define the actual working pressure of the pipe. This allows the end user to specify a pipe that meets the design requirements of a given pipeline. Ductile Iron is still the most conservatively designed pipe in the water works industry.

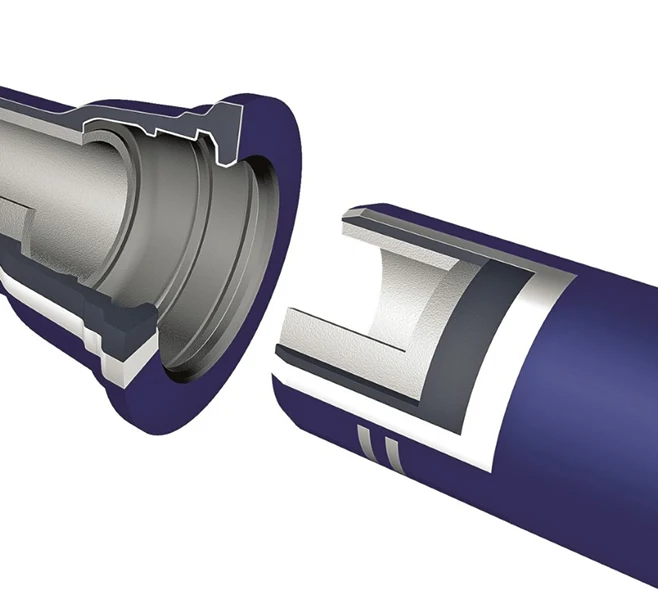

Is a bolt required for the installation of TOPSUN Boltless Restrained Joint Pipe?

No. For full length and factory welded shorts a bolt is not needed. You simply install the locking ring, rotate until the lugs align, and the joint is assembled. However, field cut pipe using a locking ring with gripping teeth a bolt is required.

When are anti-rotation wedges required for TOPSUN pipe?

Wedges are required at the 3 and 9 o'clock positions when pipe is used as a carrier pipe within a casing. As pipe is pushed through casing it has a tendency to roll, these wedges are used to insure the pipe stays locked together when the pipe is being pushed through the casing. It is recommended to test pipe in casings separately from the rest of the waterline.

Is it alright if the TOPSUN ring spins freely inside the bell?

Yes, as long as the pipe is installed properly and there is a weldment on the pipe. The pipe is designed so the ring rotates easily, but care should be taken to insure the lugs are properly aligned prior to backfill. When the pipe is put under pressure it will move until lugs engage and a positive restraint is achieved.

What is gauged pipe?

All pipes are checked to insure that the spigot end, bell, and socket comply with requirements of AWWA C151/A21.51. Gauged pipe is pipe which has physically been checked to insure the entire length, to within 2 feet of the bell, falls below the maximum O.D. This allows for easier installation of fittings on this pipe. We mark this pipe with a greenmark on the bell of the pipe. It is recommended that all pipes be checked in the field with an O.D. tape prior to cutting any pipe.

Are all Ductile Iron Pipe push-on joint gaskets interchangeable?

No. There are two types of joint design for ductile iron, Tyton ® and Fastite®. You should verify the manufacturer of the pipe and use gaskets provided by the manufacturer.

How much deflection is allowed for ductile iron per joint?

The allowable defection varies from 2 to 5 degrees depending on the size and type of joint used. See our deflection charts for more information.

Are small cracks in the cement lining normal?

Yes. These cracks (sometimes resembling a spider web) are caused by the fact that iron and cement have different thermal expansion coefficients. As the temperature changes prior to installation these cracks can occur. These cracks are normal and are of little concern due to a process called autogenous healing. Simply stated, autogenous healing is the ability of cement to heal itself. In the presence of moisture, cement extrudes calcium hydroxide which, upon exposure to the atmosphere, is converted to calcium carbonate which seals the crack. These calcium carbonate crystals are formed when the carbon dioxide in the air and water carbonates the free calcium oxide in the cement and the calcium hydroxide liberated by the hydration of the tricalcium silicate of the cement.

How do you repair cement lining in Ductile Iron Pipe?

Cement mortar lining can be repaired following the instructions in ANSI/AWWA C104/A21.4 "Cement-Mortar Lining for Ductile-Iron Pipe and Fittings for Water". To make the repair first the damaged lining needs to be removed to the metal leaving the edges perpendicular to the pipe wall. Second, prepare a stiff mortar that is one part cement to two parts sand. Third, trowel the mortar over the repair area so it is smooth with the existing lining. Fourth, keep the repaired area moist by applying seal coat over the repaired area.

When is it required to use Polyethylene encasement?

In most soils Ductile Iron needs no additional corrosion protection. However, polyethylene encasement should be used when the soils on the project are determined to be corrosive to Ductile Iron Pipe using the ten point soil evaluation procedure. This procedure is included in the Appendix to ANSI/AWWA C105/A21.5. For assistance with this procedure please contact your local sales representative or DIPRA.

How much pipe is a truckload quantity?

The number of pipe per truckload varies depending on the size and class of pipe. See the below sheets for this information.

When bronze wedges are used, how many are used per joint?

When bronze wedges are specified you use 2 per joint on 3" through 12" pipe and 4 per joint on larger diameters. Each wedge is driven into the opening between the plain end and the bell until snug. When four wedges are used, they are inserted side by side, in pairs.

Topsun service undertakes to provide you with long-term sustainable technical solutions, permanent innovation and expertise from our specialists.

A sustainable partnership based on trust, Topsun is present beside you.

[null]