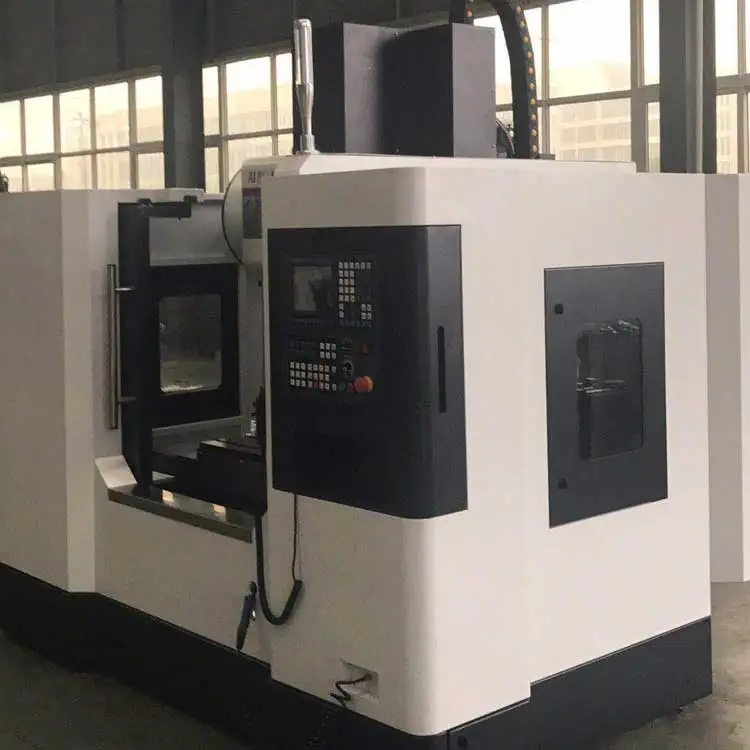

Vmc650 Китай низкая стоимость выгодная цена Универсальная металлическая 3 оси вертикальный фрезерный станок с ЧПУ (числовым программным управлением) для

- Категория: >>>

- Поставщик: Taian,Haishu,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 22015.32 $* | 23116.72 $* |

| Aug-19-2025 | 21830.85 $* | 22922.70 $* |

| Jul-19-2025 | 18315.0 $* | 19231.11 $* |

| Jun-19-2025 | 21460.89 $* | 22533.15 $* |

| May-19-2025 | 18685.76 $* | 19619.30 $* |

| Apr-19-2025 | 21090.78 $* | 22145.73 $* |

| Mar-19-2025 | 20905.28 $* | 21950.33 $* |

| Feb-19-2025 | 20720.81 $* | 21756.23 $* |

| Jan-19-2025 | 20535.3 $* | 21562.55 $* |

Характеристики

vmc650 China low cost best price universal metal 3 axis vertical cnc milling machine for sale

First, the main purpose:

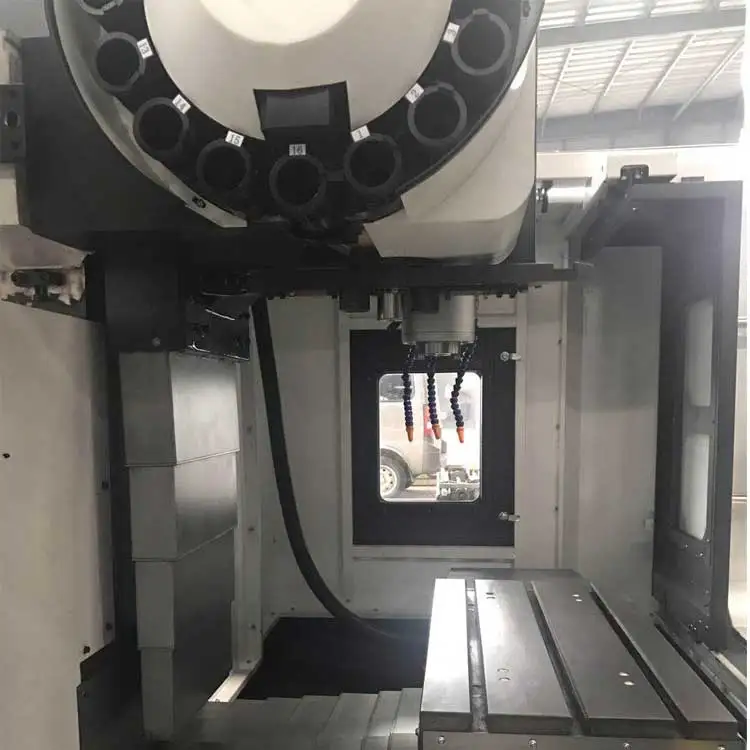

The machining center is a vertical bed structure, the feed axis is X, Y, Z three coordinate control, the maximum fast moving speed is up to 20m/min; the main shaft is servo motor power drive, the power is 3.7Kw, the maximum speed is 8000rpm The double-nut pre-pressed C3 ball screw is used, and the pre-stretching mechanism is adopted at both ends, which greatly eliminates the influence of thermal deformation on the precision of the machine tool. The positioning accuracy of the machine tool is 0.008 mm; the bucket type and the disc type are optional. Kind of tool magazine, accurate and reliable tool change; machine tool numerical control operating system has customer choice, machine tool can realize complex clamping of various discs, plates, shells, cams, molds, etc., complete drilling, milling, boring, expansion , hinge, tapping and other processes, suitable for the production of multi-variety, small and medium-sized products, can display its superiority for the processing of complex and high-precision parts; the machine tool can be complex if it is equipped with the fourth and fifth axes. Efficient, high-precision automated machining of rotary parts. The machine tool is suitable for high-efficiency and high-precision automatic processing of small and medium-sized parts in aerospace, military and national defense, automobile and motorcycle, engineering machinery, refrigeration and petrochemical, rolling stock and other industries.

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

Main Features

1. High rigidity: the bed-type machining center structure is adopted. The machine tool is composed of base, sliding seat, work table, column and headstock; the main basic parts are analyzed by finite element structure, the structure is reasonable and the rigidity is large; all machine tool castings are Thermal aging treatment, precision has long-term stability.

2. The machine tool adopts high-speed, high-precision and rigid Taiwan spindle unit. The spindle material is made of high-performance alloy steel. The P4 high-speed precision bearing for the spindle is used, and the high-speed grease is used. The spindle speed reaches 8000 rpm and the spindle radial runout is less than 0.008/300. .

Spindle unit appearance diagram Spindle floating tooling system

3.The X, Y and Z direction feed adopts the C3 grade double nut preloaded precision ball screw. The servo motor is directly connected with the lead screw through the high torque and low inertia inlet elastic coupling, and the lead screw support adopts the pretensioning structure. It can eliminate the backlash of the transmission and pre-compensate the influence of thermal deformation on the precision of the machine during long-term operation, ensuring the positioning accuracy and repeat positioning accuracy;

Taian Haishu Machinery co.,Ltd. specializes in the design, production and sales of CNC machine tools. The leading products are "sea number" brand CNC lathes, turning centers, machining centers, etc. The company was established in March 2001 and covers an area of 12,000 square meters. It was re-registered after the transformation of the company in November 2010. Has passed CE certification and SGS certification, TUV certification, BV certification, ISO9001 certification.we has won many honors such as national level and upgrade. It is a charity and love enterprise in Shandong Province.

Pre-Sales Service

* Inquiry and consulting support.

* 24 Hours on services Phone, email and in person support

* View our Factory.

* Electrical & mechanical technical support

* Parts ordering

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Regular Machine Inspection

* Stay in touch with the customers even after the deal. never ignore their calls.

* Engineers available to service machinery overseas.

Packing

Standard export wooden box packaging

Free fumigation materia

Delivery

Conventional CNC machine tools for 7 to 15 days

Custom CNC lathe products for 15 to 30 days

car wheel processing unit

100% Response Rate

CKL35 wheel repair CNC lathe

99.8% Response Rate

CK6160Q diamond cutting wheel lathe machine

99.9% Response Rate

1.Q:Can we pay by L/C?

A:Yes, we can do T/T, L/C etc.

2.Q: What is your payment terms?

A:Our payment term is 30% T/T in advance, 70% T/T before shipment.It is negotiable.

3.Q: What is your delivery time?

A:Usually, one machine takes 10-30 days. IF we have in stock, we can arrange

shipment as soon as we receive the payment.

4.Q: Can we go to your factory and learn how to use the machine?

A:We sincerely welcome you come to our beautiful city. The training is free. It would

be great honor to us.

5.Q:Can you arrange training in our place after we bought your machine?

A:We can arrange oversea training. Buyers will be responsible to the costs.

6.Q:How many Voltage ? How many Phases 1 or 3? How many hertz (Hz)? of your

machine?

A:Our standard is 3 phase, 380V, 50/60Hz. All can be customer made.

7.Q: Do you have CE certification?

A: yes, we have CE certification, machine quality is guaranteed.

8.Q: Is your company a factory or trading company?

A: We are factory and have more than 18 years production experience.

9.Q: How can I get the quotation?

A:You can send the inquiry on alibaba.com, or send email to us. It is better if you can

tell what is your detailed requests. We will reply to you within 1 hour.

10.Q:What is the Control of your lathe? Can I change it to other brand?

A:The standard control of our lathe is GSK. You also can change other controls,

such as FANUC,Siemens and so on.