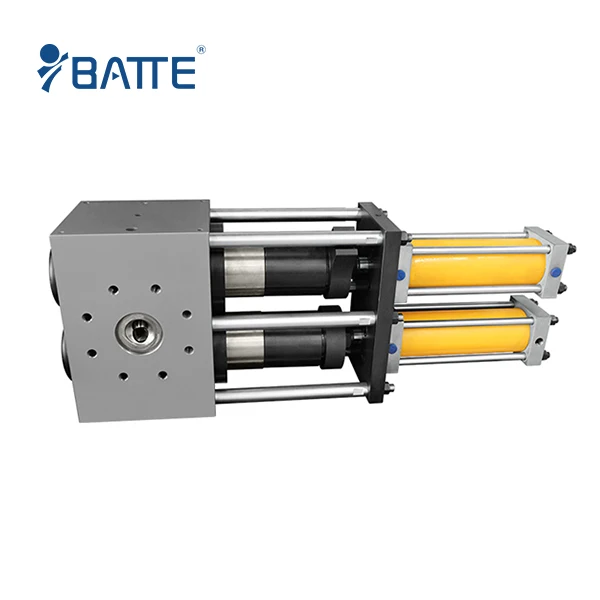

Сменный экран фильтра с двойной колонкой для экструдера nbr ldpe PET

- Категория: Запасные части для станков для резины и пластика >>>

- Поставщик: Zhengzhou,Bate,Melt,Pumps,Co.,Ltd.,[Henan,China]Zhengzhou

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 291350.74 $* | 305918.0 $* |

| Aug-17-2025 | 288902.17 $* | 303347.70 $* |

| Jul-17-2025 | 242384.33 $* | 254503.93 $* |

| Jun-17-2025 | 284005.46 $* | 298205.59 $* |

| May-17-2025 | 247280.68 $* | 259644.42 $* |

| Apr-17-2025 | 279108.2 $* | 293063.9 $* |

| Mar-17-2025 | 276660.46 $* | 290493.64 $* |

| Feb-17-2025 | 274212.24 $* | 287923.6 $* |

| Jan-17-2025 | 271764.21 $* | 285352.44 $* |

Характеристики

Propene Polymer screen changer for pp extruder

Introduction of ZB-DP-4R-280 screen changer for pp extruder

- As four-channel four screen cavities screen changer, four screen cavities can work simultaneously which can provide uninterrupted operation.

- Exhaust structure can fully exhaust the gas in material and the other screen cavities, which can prevent gas coming into being during production, improve the product quality.

- Four-channel double screen cavities increase the filter area, which can improve the output and quality.

- Larger filter area is suitable for various different material and extrusion.

- Well sealed, rigid sealing, long service life.

- This series screen changer is suitable for high productivity, high efficiency, high quantity and continuous production of large extrusion plant.

- Reasonable structure, easy to operate, high quality.

- Customization, according to the customer special request to design and process

- Safety hood is equipped.

- It’s suitable for chemical fiber, blown film, flat film, cast film, pipe, plate, wire, fiber, granulating, recycling, pelletizing, etc.

Parameters of ZB-DP-4R-280 screen changer for pp extruder

|

Type |

Capacity (kg/h) |

Dimension (mm) |

Screen size |

Heater |

|||||

|

L1 |

L2 |

L3 |

Diameter (mm) |

Area (cm2) |

Quantity |

Voltage (v) |

Power (w) |

||

|

ZB-DP-4R-120 |

260-760 |

180 |

1160 |

220 |

100 |

78*4 |

6 |

230/400 |

1000/1300 |

|

ZB-DP-4R-145 |

580-1400 |

225 |

1420 |

270 |

125 |

123*4 |

6 |

230/400 |

2000/2400 |

|

ZB-DP-4R-170 |

750-2000 |

260 |

1595 |

310 |

150 |

177*4 |

6 |

230/400 |

3000/3500 |

|

ZB-DP-4R-195 |

1350-3000 |

315 |

1890 |

380 |

175 |

240*4 |

6 |

230/400 |

3500/4000 |

|

ZB-DP-4R-220 |

1650-3800 |

350 |

2100 |

410 |

200 |

314*4 |

10 |

230/400 |

3500/4000 |

|

ZB-DP-4R-250 |

2100-5200 |

405 |

2395 |

460 |

230 |

415*4 |

12 |

230/400 |

3500/4000 |

|

ZB-DP-4R-280 |

4500-8500 |

450 |

2760 |

500 |

250 |

490*4 |

12 |

230/400 |

4200/5000 |

Notes: The capacity will be affected by the fluidity, filter fineness and purity of materials.

BATTE screen changer can not only filter the impurities, but also can significantly improve the plasticizing and homogenization effect of the raw material. In this way, it can make the product structure more homogeneous and product surface more smooth, thus improve the quality of extruded products. In a word, BATTE screen changer can reduce the unit cost and increase hourly output.

Batte persists in the business philosophy that technology goes with quality: technology is the root, innovation is the soul, customers come first.

1. Installation Services: During the period of installation and debugging, we shall offer training about effective operation and maintenance.

2. Technical Services: We can assist our clients to solve all kind of technical problems with our capable technical team, and we own adequate experience for production line transformation project.

- When trainning your operators, our engineers will give them advice on how to operate the machines correctly;

- We will send you the operation manual which can help you operate the machins properly, it can also help you to solve the common problems;

- Call us at any time if you have problems about our equipment;

- If needed, we will send engineers to your site to solve your problems.

3. Warranty Services: We offer free after sale service except the engineers' traveling expense for any quality problem occurs during our 12 months warranty period.

4. Providing some documents needed for your customs clearance, like commercial invoice, packing list, certificate of origin etc;

1. Which screen changer model we should use?

Before recommending our proper screen changer model for you, we want to confirm with you the points as follows:

1.1. Do you use the extruder during production? Is it single screw extruder or twin screw one?

1.2. The materials you use, are they raw materials or recycled ones?

1.3. The hourly output;

1.4. The final products;

1.5. Do you use screen changer before? If it is, please tell us the filtration fitness and screen diameter;

1.6. How often you need to change screen;

1.7. The max. Operating pressure;

2. What is your MOQ?

At present, our MOQ is 1 set;

3. How long is the delivery time?

In general, the delivery time is 4-5 weeks.

4. What is your guarantee term?

The warranty period for our products is one year.During the warranty period, the seller is responsible for replacing free damageable parts , while the buyer pays for freight.

5. How about the oversea installation and debugging?

Our engineer can be assigned for installation and debugging. Or we can use long-distance technical assistance based on Industry 4.0

Send your Inquiry Details in the Below, Click "Send" Now!

↓↓↓

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com