Пластиковые бутылки для пластиковых отходов ПЭТ бутылка

- Категория: Plastic Recycling Machinery >>>

- Поставщик: Zhangjiagang,Sino-Tech,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 102340.39 $* | 107457.72 $* |

| Aug-16-2025 | 101480.13 $* | 106554.56 $* |

| Jul-16-2025 | 85140.74 $* | 89397.88 $* |

| Jun-16-2025 | 99760.11 $* | 104748.96 $* |

| May-16-2025 | 86860.91 $* | 91203.84 $* |

| Apr-16-2025 | 98040.20 $* | 102942.66 $* |

| Mar-16-2025 | 97180.56 $* | 102039.64 $* |

| Feb-16-2025 | 96320.69 $* | 101136.1 $* |

| Jan-16-2025 | 95460.21 $* | 100233.95 $* |

Характеристики

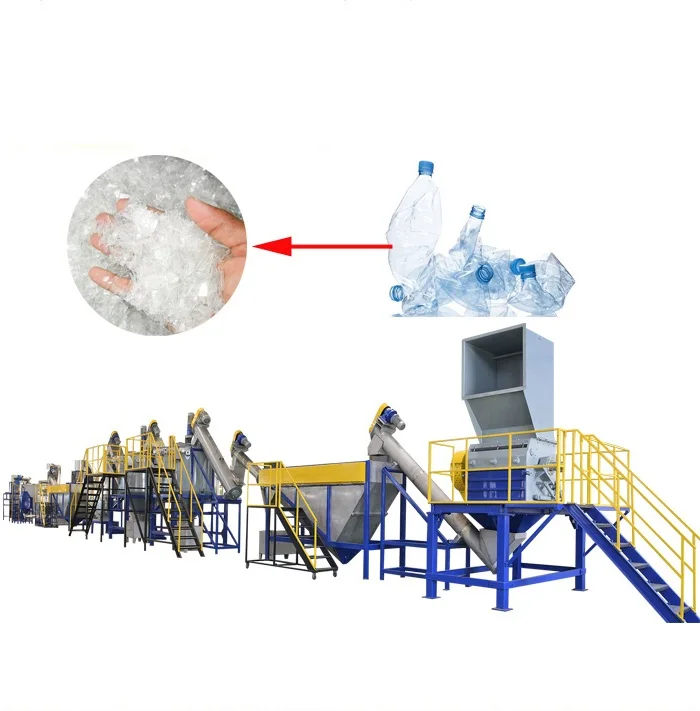

Plastic bottles plastic waste PET bottle recycling line

Function of PET bottle recycling line:

To separate PET bottles to flakes from PE/ PP label, cap, oil, garbage, protect the environment, Avoid white pollution.

This recycling line is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing system, etc.

This PET bottle flakes crushing, recycling and washing production line can easily wash and recycle waste PET bottle flakes. Waste and dirty PET bottle flakes can be treated step by step by this recycling machine. It is special for washing PET bottles flakes. We can help to attach equipment at the end of the washing line so that the completely dry flakes can be collected and packed directly after been washed.

The whole production line can designed based on how dirty the PET flakes are, and make sure of the quality of the final products.

Coordinating the production line with follow programmed work (granulating system), and it will make waste and dirty PET bottles to be the PET granule material and in order to producing new PET bottles.

Characteristic of PET bottle recycling line:

1. High automation level, try best to reduce your cost on labor (especially for three shifts) and ensure high processing capacity: 500-3500kg/hr

2. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 stainless steel; Ensure no second pollution to flakes.

4. Ideal impurity removal effect. Here is from our customer's feedback.

Input capacity | 500kg/h | 1000 kg/h | 2000 kg/h |

Workshop(M*M*M) | 42 (L)×10(W)×6(H) | 55(L)×15(W)×6(H) | 70(L)×18(W)×6(H) |

Ancillary staff | 6Persons | 8 Persons | 12 Persons |

156KW | 307KW | 420KW | |

2Ton/h | 3.5Ton/h | 5 Ton/h | |

Final product | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: max.20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: Max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

Flow chart of PET bottle recycling line:

1) Belt Conveyor: The materials go into the crusher by the crawler belt, which is move by inside scroll wheel.

2) Label Separator: Remove the label from the bottles.

3) Manual Sorting Belt: If the label still in the bottle, worker can remove the label by hand. In addition, can separate the different color by hand.

4) Belt Conveyor: The materials go into the crusher by the crawler belt, which is move by inside scroll wheel.

5) Crusher: Crush the material.

6) Screw Loader: Put the flakes into the Hot washer to clean.

7) Hot Washer: If the bottle is very dirty, like oil, sand, it must be use hot washer.

8) Screw Loader: Put the flakes into the High-speed Friction Washer to clean.

9) High-speed Friction Washer: After crushing material from enters the mouth, through the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect.

10) Floating Washer 1: It used in cleaning pet flakes, make the flakes cleaner and whiter. Also is the necessary equipment of the bottle and bottle cap.

11) Floating Washer 2: It used in cleaning pet flakes, make the flakes cleaner and whiter. Also is the necessary equipment of the bottle and bottle cap.

12) Dewatering: Rejection the water from the flakes, moisture content is less than 2%.

13) Drying Pipeline

14) Silo: Storage materials.

15) Electrical Control Cabinet: PLC control.

Photos of PET bottle recycling line:

Crusher machine:

Cold floating washing tank:

PET flakes hot washer, hot washing machine:

PET flakes high speed friction washing machine:

| Supplier |

Microcomputer Control System | MITSUBISHI PLC, Japan |

Touch Screen | HITECH, Taiwan |

Contactor | SCHNEIDER, France |

Air Switch | SCHNEIDER, France |

Motor | SIMENS BEIDE, Germany |

Power Resource | MEAN WELL, Taiwan |

Inverter | MITSUBISHI, Japan |

Relay | OMRON, Japan |