Лидер продаж литой станок для алюминиевых заготовок Литой Станок

- Категория: Metal Casting Machinery >>>

- Поставщик: Shanghai,Hongxun,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.16 $* | 0.54 $* |

| Aug-19-2025 | 0.38 $* | 0.27 $* |

| Jul-19-2025 | 0.94 $* | 0.15 $* |

| Jun-19-2025 | 0.57 $* | 0.42 $* |

| May-19-2025 | 0.51 $* | 0.29 $* |

| Apr-19-2025 | 0.59 $* | 0.53 $* |

| Mar-19-2025 | 0.8 $* | 0.44 $* |

| Feb-19-2025 | 0.55 $* | 0.83 $* |

| Jan-19-2025 | 0.85 $* | 0.35 $* |

Характеристики

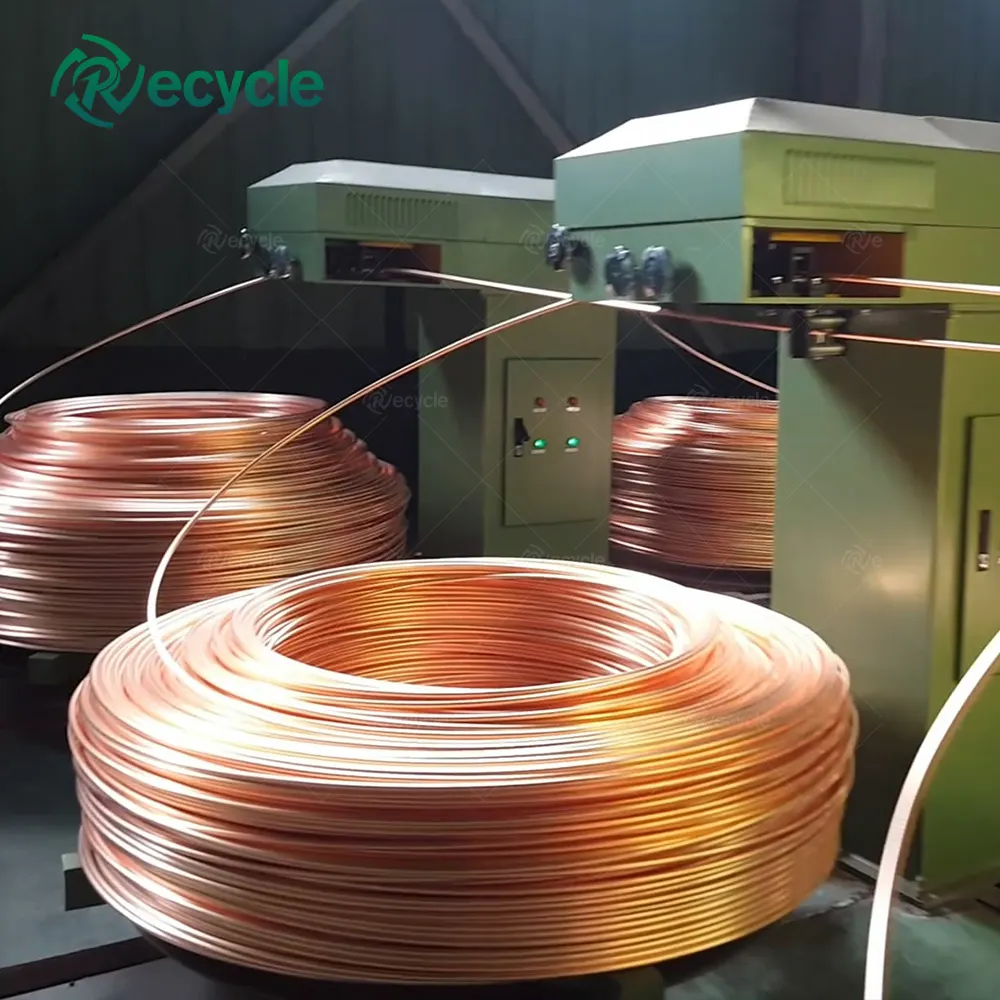

aluminum melting furnace for casting line

A,5T Square direct pull fixed type of aluminum melting furnace

Main usage: Non-ferrous metal(Aluminum)to be smelted

1,Liquid aluminum capacity is for 5T, vault draw type of furnace door, the electric lifting of furnace door, aluminum liquid discharge.

2,Furnace shell is for 8mm steel plate. The steel type of furnace wall for 12 # channels. profile steel of electrical lifting rack: 12# steel channel.

3,The thickness of refractory for furnace wall about 500mm,Molten pool adopted level 1 LZ - 70 with high aluminum bricks, insulation materials and high-density cast able material. Above part of molten pool use level 1 refractory bricks, Insulating layer use diatomite heat preservation brick and siliceous aluminous fiber;Furnace door is with superior , low cement crater of high strength cast able;Adopting level 1 fire-proof bricks masonry arched in the top of furnace, use high strength cast able around the oven outlet.

Technical data:

1,Furnace type stationary type

2,The external dimension of furnace body confirmed as the actual site

3,The capacity ≥5T

4,The weight of furnace door ≈600kg

5,The quantity of furnace door 1 piece

6,The operation of furnace door Motor-driven

7,The power of furnace door: 4KW

8,The maximum operation temperature(Aluminum water) ≤860℃

9,Normal operation temperature(Aluminum water) 720℃~750℃

10,The rake of furnace bottom and door ≈10-20°

11, The discharge form of Aluminum water manual

12,Discharging quantity 1 piece

13,The diameter of discharging hole ≈50mm

B.5T manual casting winch system

Technical data:

1.Digital display: casting speed, length, water temperature.so on

2.Winch adaptive capacity ≥10T

3.Tipping system exert ≤5T

4.Tipping platform titled holding Angle ≤90°

5.Well rack adaptive capacity ≥50T

6.Winch stroke 30-250m/min

7.Precision casting speed ±0.1

8.Casting length control precision(setpoint) ≤±5%

9.The deviation of lift platform within the scope of the length and vertical line ±5mm

10.Lift platform reset accuracy ≤±5.0mm

11.Lift platform rapid rise and fall, there are loads ≥500mm/min

12.Steel structure lifting platform on surface machining, a dummy positioning device design,

13.Electrical control device size setting as actual site

14.Casting ingot bend <10mm/the length of whole ingot

15.Hydraulic medium normal working temperature 10-50℃

16.Working oil medium of hydraulic station 68# anti-wear hydraulic oil

17.Total power of equipment 9KW

Single set of 5 t cable casting machine, the main scope of supply but are not limited to ensure the integrity, including:

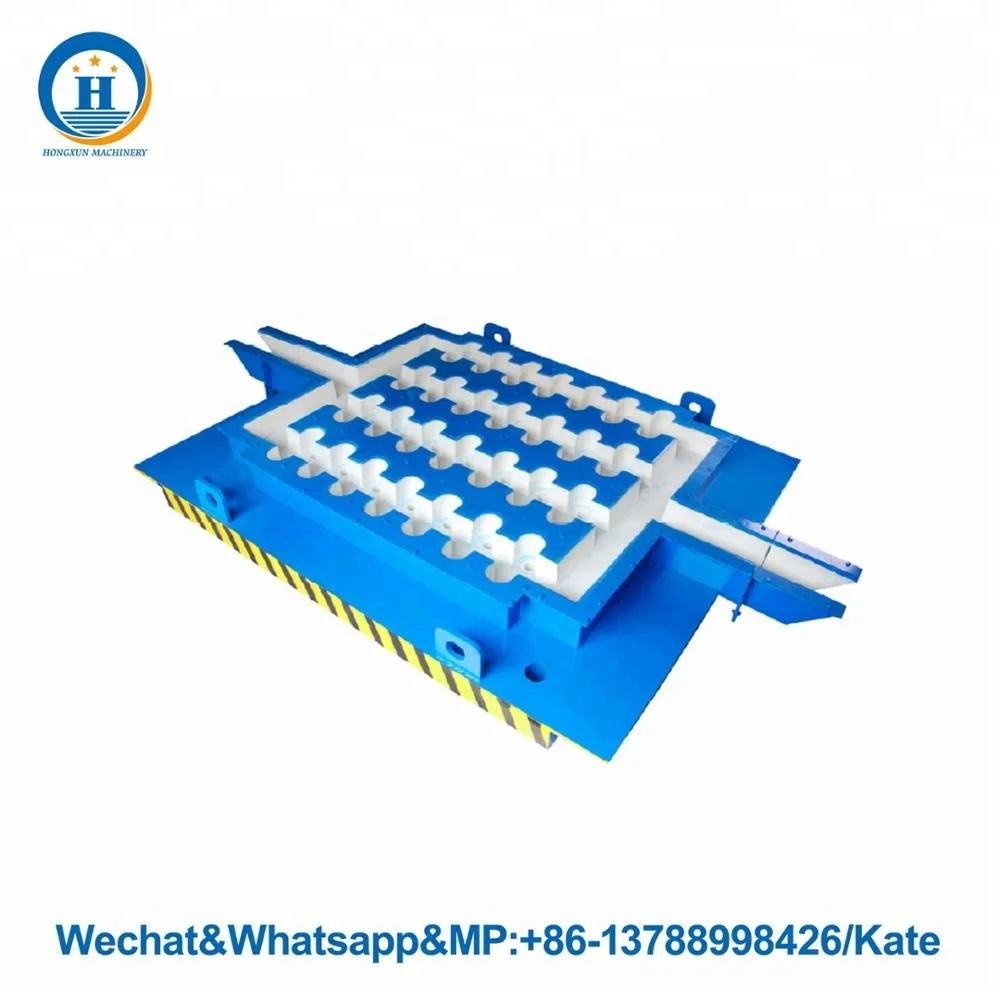

C.Casting mold

The size of casting alloy | Casting water pressure | Casting cooling water temperature | The maximum flow of cooling water(not less than) |

φ127 can be customized | 2-5kgf/cm2 (adjustable) | 10-35℃ | 400m³/h |

1. Equipment description

1. Equipment description1.1 Equipment functions

Used for cutting alloy round casting, which can realize the cutting of scale. high efficiency, with fast speed in cutting

1.2 Equipment composition

Cutting machine is mainly comprised of feeding channel, sawing host, scale device etc , etc.

2. Processing description

Aluminum rods with cranes sawing machine hang to the storage material table with sawing machine, store material platform will convey the alloy casted to feed the material rail. In the meantime, roller machine conveyed the material to the host machine. According to set the top-end length feed to be in position,Scale device put alloy round cast scale according to the length of setting, host machine start to cut, after sawing, finished alloy round casting ingot discharged to be rolled.

3. Technical data

Sawing diameter: ≤200mm

Cooling mode: Mandatory water-cooling

Main machine power: 15KW