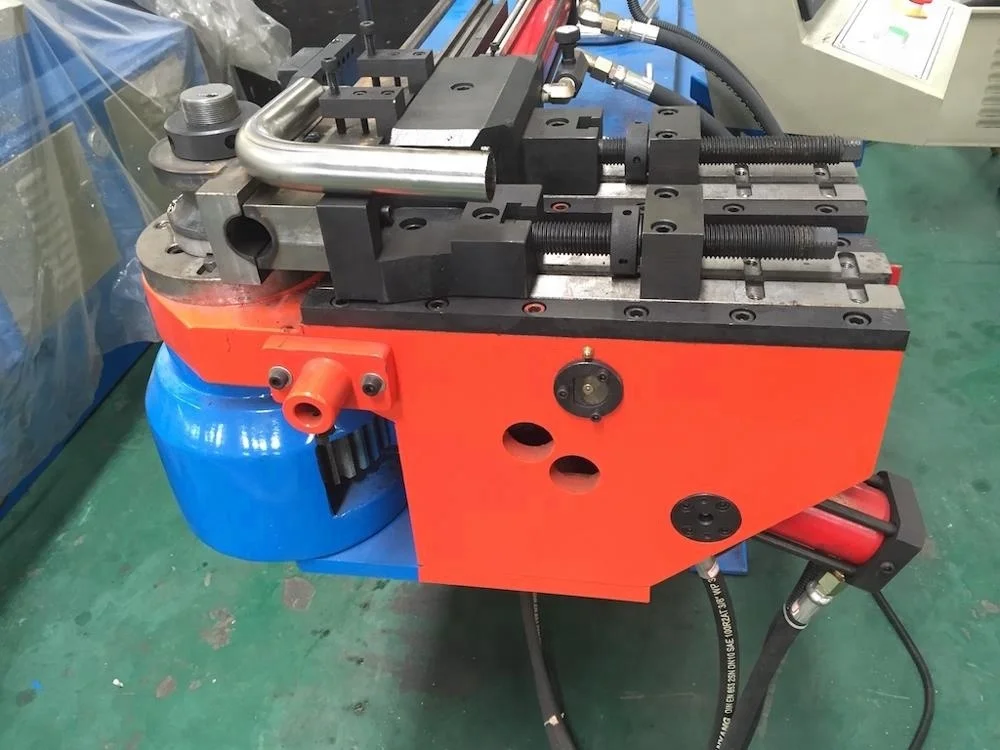

Полуавтоматический Гидравлический трубогибочный станок

- Категория: Pipe and Tube Bending Machines >>>

- Поставщик: Zhangjiagang,Sanco,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.81 $* | 0.76 $* |

| Aug-16-2025 | 0.62 $* | 0.11 $* |

| Jul-16-2025 | 0.81 $* | 0.2 $* |

| Jun-16-2025 | 0.37 $* | 0.14 $* |

| May-16-2025 | 0.36 $* | 0.35 $* |

| Apr-16-2025 | 0.41 $* | 0.35 $* |

| Mar-16-2025 | 0.78 $* | 0.76 $* |

| Feb-16-2025 | 0.24 $* | 0.88 $* |

| Jan-16-2025 | 0.38 $* | 0.17 $* |

Характеристики

| Item | Name | Data |

| 1 | Max bending capacity | Φ50 mm×2 mm |

| 2 | Max bending radius | R220mm |

| Can according to customer’s requirement | ||

| 3 | Min bending radius | R20mm |

| 4 | Standard Mandrel Length | 1700mm |

| Can according to customer’s requirement | ||

| 5 | Max bending degree | 190 Degree |

| 6 | Control Panel | PLC |

| 8 | Bending unit | 16 Pieces |

| 9 | Bending Accuracy | ±0.1 mm |

| 10 | Oil motor power | 5.5 Kw |

| 11 | Max pressure | 12 MPa |

| 12 | Hydraulic control system | Magnetic exchange valve |

| Japan Yuken | ||

| 13 | Oil tank | 180 L |

| 14 | Machine weight | 1300 Kg |

| 15 | Machine size | 3100×700×1100 mm |

1. Manufacturer warrants the products to be free from defects in material and workmanship for 12 months from the date of shipment to the original purchaser only. We will send parts (FREE) use DHL for your replacing. If the machine has worse running problems, we will send engineer to your factory for maintenance.

2. NOTE: All tooling is considered wear items which not covered under machine warranty.

3. Sample Tubes: Customer should supply sample material required for final adjustment of machine and tooling, quantities to be determined. Freight charges are the responsibility of customer.

4. Training & Setup: Additional

Machine should be placed in position and main power connected prior to setup and training at customer site. Customer should pay for travel plus related expenses (may include hotel, airfare, and rental car etc.) We also welcome customer send people here for training how to operate machines.

Lead time: One week, and customer should pay all relative expenses by themselves.

1. Steel furniture, air conditioning, refrigeration, sanitary industry (for thin-walled tube, producing no wrinkle)

2. Automobile parts (brake tubing, bumpers, mufflers, exhaust pipes, car seat)

3. Motorcycle manufacturing, bicycle manufacturing (handlebars, frame), fitness equipment

4. Shipbuilding, boiler industry (for thick-walled tubes, to ensure bending ovality and thinning rate)

1. Q: Are you a manufacturer or trading company?

A: We are a manufacturer of more than 20 years. We are professional producing metal pipe/tube processing machinery only

2. Q: How to choose the pipe/tube bending machines?

A: Please provide us following details or is better drawings:

- Max. outside diameter:

- Wall thickness range:

- Bending radius (CLR):

- The pipe material:

- The drawings if possible:

3. Q: What is the difference for NC, NCMP and CNC machines?

A: NC is standard hydraulic pipe bending machines, feeding and rotation are manual, and bending is hydraulic automatic.

NCMP is semi-automatic pipe bending machines, mechanical gear feeding, servo motor automatic angle rotation and hydraulic automatic bending.

CNC is fully automatic pipe bending machines, servo motor for feeding and rotations, and hydraulic or servo motor for bending, multiple tooling stack are available for two and more different bending radius (CLR).

4. Q: What is the machine’s control?

A: Standard control is Mitsubishi PLC + touch screen. If machine is CNC with more functions, Industrial computer is a good option with function of 3D simulation.

5. Q: What is the biggest bending capacity you could offer?

A: The biggest cold bending capacity is 325mm outside diameter. For Hot bending, is now 1000mm

6. Q: How is the training and after sales service?

1. Customer come to our factory to inspect the machine and learn how to use machine.

2. We take video of how to install machine and tooling step by step, and make video of how to operate the machine. In this way, customer ca have good knowledge of the machine operation, and no need to fly.

3. We sent ourengineer to go abroad to customer's plant to do the installtion and tranning.