Пользовательский литой стальной алюминиевый сплав колесный

- Категория: Колеса для легкового автомобиля >>>

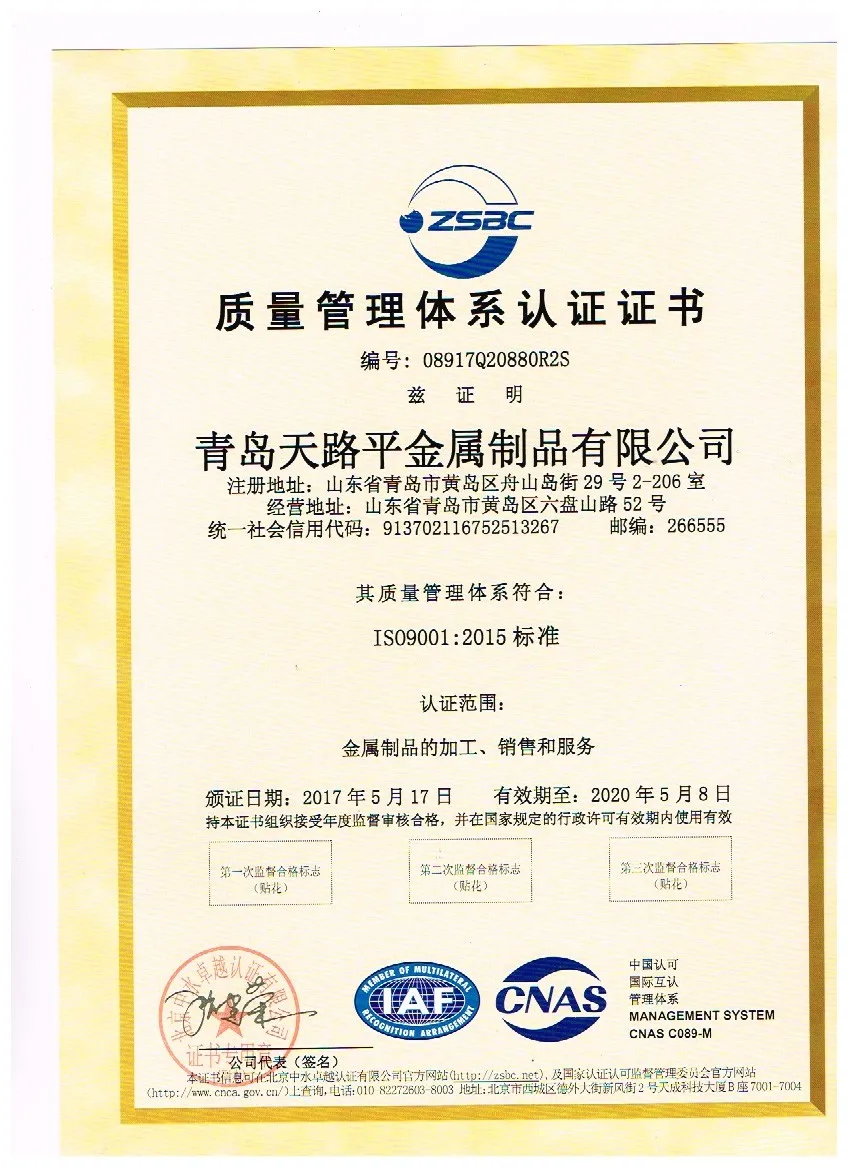

- Поставщик: Qingdao,Tianluping,Metal,Products,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-17-2025 | 4.10 $* | 4.12 $* |

| Jul-17-2025 | 3.19 $* | 3.40 $* |

| Jun-17-2025 | 4.46 $* | 4.21 $* |

| May-17-2025 | 4.46 $* | 4.50 $* |

| Apr-17-2025 | 3.71 $* | 3.66 $* |

| Mar-17-2025 | 4.70 $* | 4.80 $* |

| Feb-17-2025 | 4.71 $* | 4.67 $* |

| Jan-17-2025 | 4.71 $* | 4.43 $* |

Характеристики

OEM steel car wheels rim

In gravity die casting molten aluminium is poured into a metallic tool. The casting temperature is about 750°C. The tolerances and surface finish are good. The use of sand cores in gravity die casting enables casting of very complex components.

Gravity die casting method is competitive casting method when production quantity is relatively small or when heat treatment is needed to improve the mechanical properties. This casting method gives better tolerances and surface finish than sand casting. The tooling costs are somewhat higher than by sand casting.

| \t | |||

| \t | \t | \t | \t |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | \t |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | \t |

| \t | \t | \t | |

| \t | \t | \t | |

OEM steel car wheels rim

Aluminum die casting parts

Can form complex shapes and fine details

Many material options

High strength parts

Very good surface finish and accuracy

Little need for secondary machining

OEM steel car wheels rim

Time-consuming process

High labor cost

High tooling cost

Long lead time possible

OEM steel car wheels rim

Can form complex shapes and fine details

Many material options

High strength parts

Very good surface finish and accuracy

Little need for secondary machining

OEM steel car wheels rim

Aluminum ADC12 die casting parts

Auto parts

Can form complex shapes and fine details

Many material options

High strength parts

Very good surface finish and accuracy

Little need for secondary machining

Main Features

Good dimensional accuracy

Smoother cast surface finish than sand casting

Improved mechanical properties compared to sand casting

Thinner walls can be cast compared to sand casting

Reverse draft internal pockets and forms can be cast in using preformed sand core inserts

Steel pins and inserts can be cast in to the part

Faster production times compared to other processes.

Once the tolling is proven, the product quality is very repeatable.

Outsourced Tooling setup costs can be lower than UK sand casting.

Pre-Sales Service

After-Sales Service

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate