Клей-герметик Жидкая силиконовая резина для бетона

- Категория: Rubber Raw Materials >>>

- Поставщик: Dongguan,Guochuang,Organic,Silicone,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.24 $* | 0.50 $* |

| Aug-19-2025 | 0.88 $* | 0.37 $* |

| Jul-19-2025 | 0.97 $* | 0.62 $* |

| Jun-19-2025 | 0.71 $* | 0.90 $* |

| May-19-2025 | 0.14 $* | 0.36 $* |

| Apr-19-2025 | 0.94 $* | 0.80 $* |

| Mar-19-2025 | 0.47 $* | 0.41 $* |

| Feb-19-2025 | 0.36 $* | 0.28 $* |

| Jan-19-2025 | 0.27 $* | 0.72 $* |

Характеристики

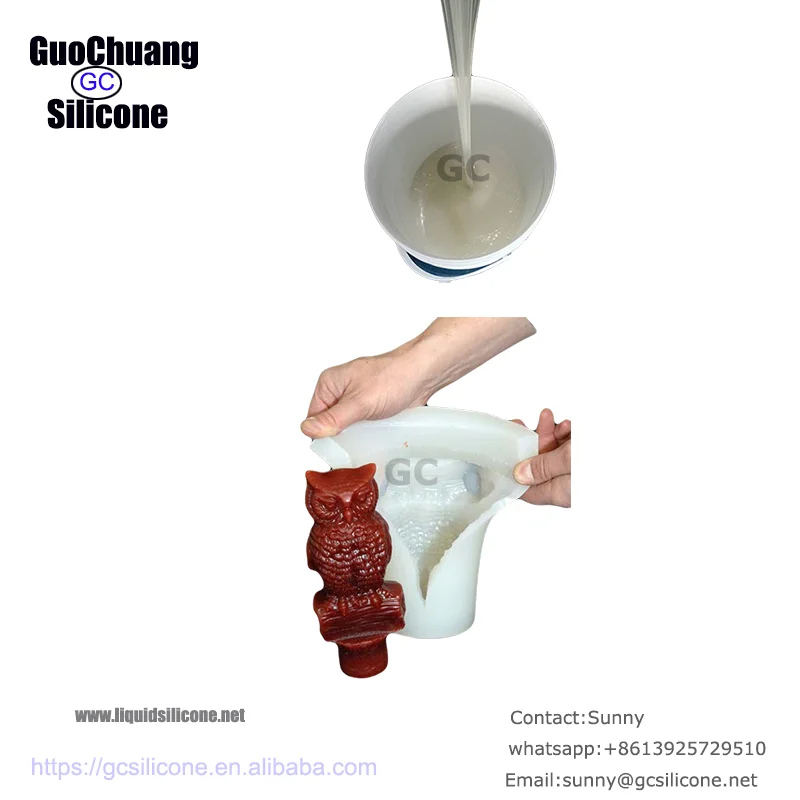

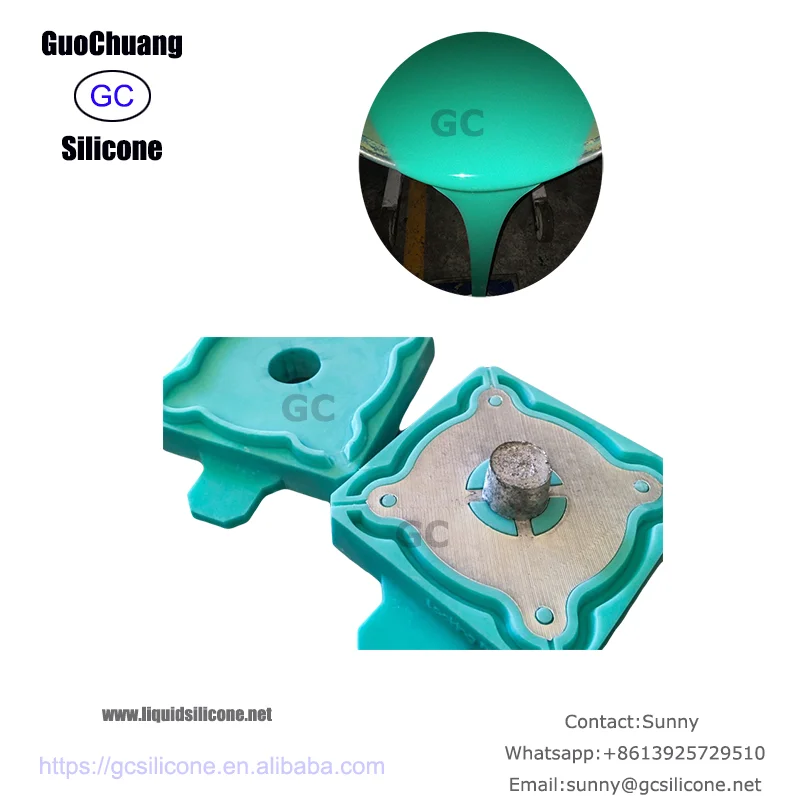

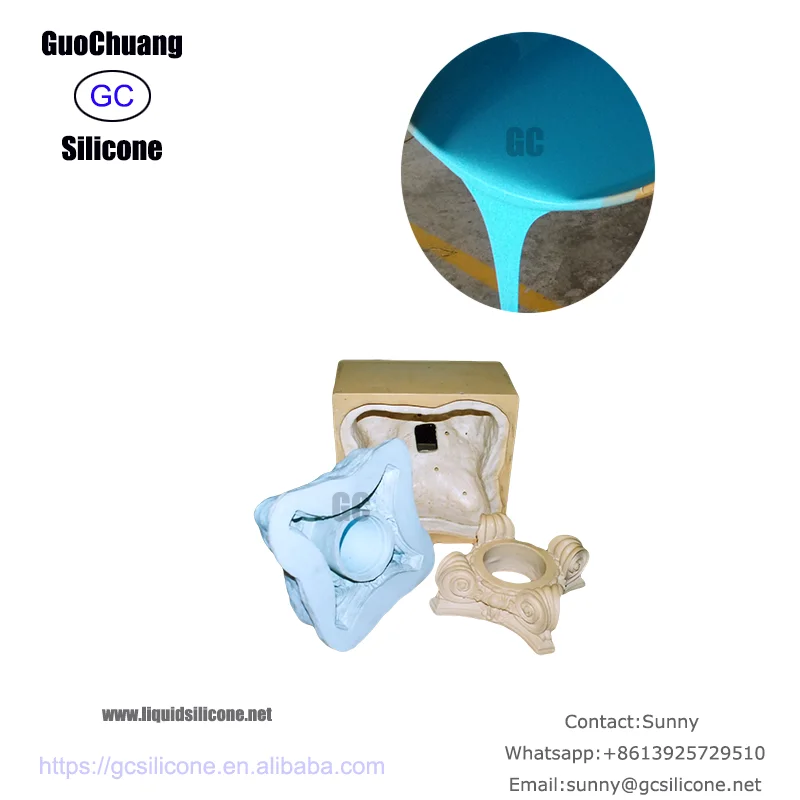

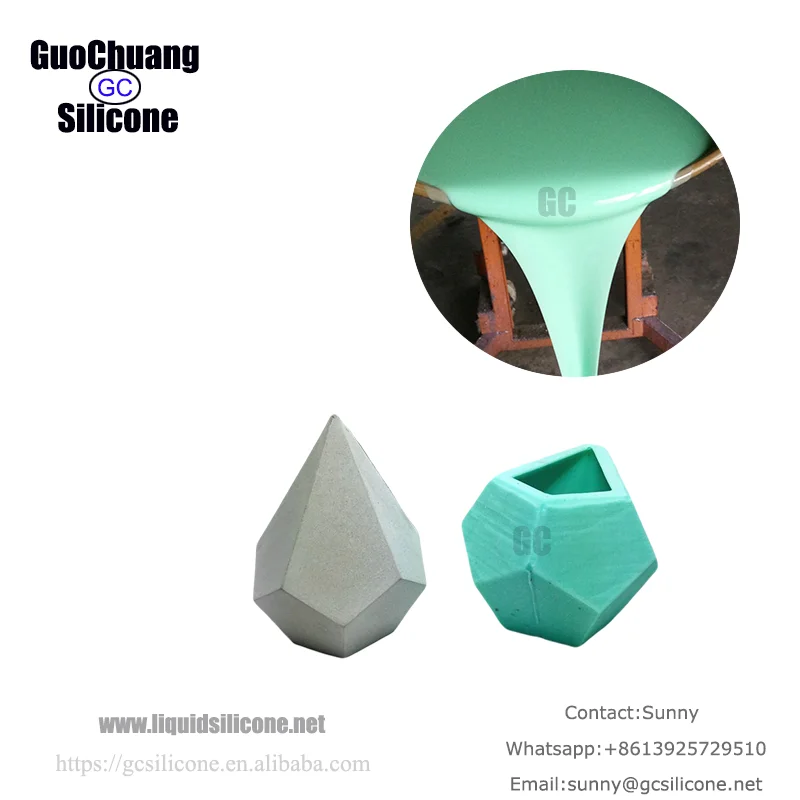

1.Description of rtv liquid silicone rubber for concrete garden pot mold

This series of product is made of special materials,it is the two-component condensed room temperature curing liquid silicone rubbers, consisted of Part A and part B. the mixed ratio is from 100:2 to 100:5 (large adjustment range of hardness).,mainly be suitable for making molds application.we have different items of different hardness, viscosity and curing time to cater to different users' requirements. Users can use it for different operations like pouring molds and brushing molds etc.

2.Characteristics of rtv liquid silicone rubber for concrete garden pot mold

*An exceptional fluidity and good operability, easy to demold

*Good tensile strength and tear strength

*Soft hardness

*Copy detailed pattern

*Good flexibility

*Eco-friendly

*Long shelf-time &lifetime

3.Application of rtv liquid silicone rubber for concrete garden pot mold

Both tin cure silicone and platinum cure silicone rubber are suitable for replicating the silicone rubber mold for cement products, as long as it with good tear strength and tensile strength. That means, it's also suitable for resin arts, polyurethane arts, culture relic ,ornamental plaster, garden sculptures, fiberglass animal,GRC,etc.

4. Datasheet of rtv liquid silicone rubber for concrete garden pot mold

| Item No. | Appearance | Hardness (shore A°) | Viscosity (CPS) | Tensile-strength( kgf /cm2 ) | Tear-strength (kgf /cm2 ) | Elongation-break(%) | Mixing ratio | operation time (25 ℃ ) | Curing time( 25 ℃) | shrinkage |

| C830 | White | 30±1 | 22000±1000 | ≥45 | ≥26 | ≥480 | 100:3 | 20-30 mins | 2~3 h | ≤0.3% |

5. Using instructions of rtv liquid silicone rubber for concrete garden pot mold

Step 1: prepare the original molds

Prepare an perfect mold modle and clean it totally(the release agent can be detergent, soapy water and Vaseline)before operation .Take 100g silicone material and 2~5g curing agent strictly and mix them evenly.

*Notes:Make sure the toys and operation tool cleaned up totally to avoid uncure problem .

Step 2: Vacuum pumping

Without exception, this step takes less than 10 minutes.(normally is 5munites) Otherwise, it will cause cross linking reaction, and no more further steps will be available.

Step 3: Pouring casting or Brushing operation

1. For simple pattern products we suggest use pouring operation way, which will be very easy to operate and demould. Pourable silicone require light viscosity which will be easy to flow smoothly and easy to de-air . (mold with fine and precision patterns with low hardness.)

2.For delicate pattern products we suggest use brushing operation way.which can copy the pattern exactly .brushing way require high viscosity which won’t be easy to flow away and easy to brush(large size molds with high hardness)

3.The amount of the curing agent can be adjusted according to the actual requirements of the customer. If molds requiring fast drying and demould, more curing agent is needed; contrarily, if molds requiring slower drying and demould, less curing agent is needed.but we don’t suggest to add silicone oil avoid oil problem.

Step 4:Demoulding:

After 35 hours later, can demould the silicone mold,It’s will be better for mold to demould after 24 hours

Notes:The curing temperature and curing time can be adjustable according to the operation conditions.

Attentions:

1. The curing speed of this product is closely related to the ambient temperature,high temperature fast curing, on the contrary, low temperature curing slow. Users can appropriately adjust the amount of curing agent to obtain the desired cure speed according to the ambient temperature level.

2. If the copying original models are ceramic, 815 resin, ABS material, wood, metal and other materials, the original models surface need use a release agent or baking mold method then reperfusion mold for avoiding sticky mold phenomenon.

3. Two parts of this series of products should be stored separately sealed, placed in a cool place, avoid the sun and rain.

4. If viscosity is increased or it has precipitation in silicone at storage period, can be used after mixing evenly, its performance unchanged.

5. This product is non-dangerous goods, if skin contacts the curing agent, can be cleaned with the suitable detergent and water; if splashed into the eyes, immediately wash with clean water at least 15 minutes, and consult a doctor.

Package

25KG/drum vacuum packing for part A +1kg/ bottle catalyst for part B

200KG/drum packing for part A +1kg/ bottle catalyst for part B

Shelf life

1. Twelve(12) months when stored under dry and cool place by original package under 25℃

We have own lab with the experienced&professional R&D and production team as well as advanced devices. Here show only parts of the whole testing.

what can we provide?

1.Free sample of 1kg for testing by UPS.

2.Various range of export trading forms: FOB,CFR,CIF,DDU.

3.Goods delivery by air or by sea.CFR price shipped by our forwarder could be even more economical than FOB price.

4.Professional own forwarder is more experienced at custom clearance issue and more guaranteed about safety shippment and delivery time.

5.To help you reduce the customs clearance fees, we can offer all kinds of Certificate of Origin related to different countries including CO, FORMA,FORME,FORMF,etc.

(1) With us your money in safe, your business in safe.

(2) Free sample for testing.

(3) Competitive price.

(4) Strict Q/C (quality of control) management system.

(5) Enough production capacity and timely delivery.

(6) We support customized package and product.

(7) Prompt shipment with professional documents.

(8) Offering professional technical support.

(9) We can make confidentiality agreement with our customs.

(10) We will be here whenever you need.