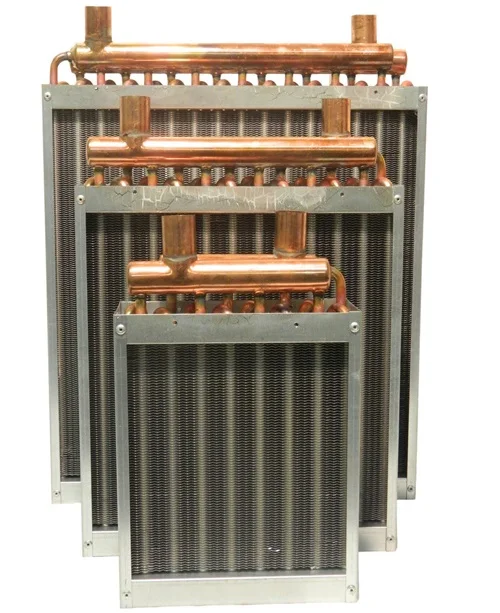

Высокое качество 20x20 воды в воздух теплообменник катушка

- Категория: >>>

- Поставщик: Changzhou,Vrcoolertech,Refrigeration,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-18-2025 | 11894.20 $* | 12132.46 $* |

| Jul-18-2025 | 9646.96 $* | 9839.55 $* |

| Jun-18-2025 | 11706.44 $* | 11940.51 $* |

| May-18-2025 | 11613.99 $* | 11845.51 $* |

| Apr-18-2025 | 9271.99 $* | 9456.46 $* |

| Mar-18-2025 | 11425.98 $* | 11654.69 $* |

| Feb-18-2025 | 11332.69 $* | 11559.11 $* |

| Jan-18-2025 | 11238.18 $* | 11463.25 $* |

Характеристики

1. Product Application

·A heat exchanger is an energy-saving device that transfers heat between materials at two or more fluids at different temperatures. It transfers heat from a higher temperature fluid to a lower temperature fluid, allowing the fluid temperature to reach the flow. Specified indicators to meet the needs of process conditions, but also one of the main equipment to improve energy efficiency.

·Mainly concentrated in the fields of petroleum, chemical, metallurgy, electric power, shipbuilding, central heating, refrigeration and air conditioning, machinery, food, pharmaceuticals, etc.

·Our factory currently focuses on large heat exchangers for various industry.

2. Raw materials

TUBE | Copper | Titanium | Aluminum | Carbon steel |

Stainless steel 304 | Stainless steel 316 | Cu-Ni(90/10) | Cu-Ni(70/30) | |

FIN | Copper | Aluminum | Stainless steel | |

Carbon steel | Titanium | |||

FRAME | Galvanized | Aluminum | Stainless steel |

Details of materials

TUBES

We make tubes of different diameters, with a greater number of thicknesses and different materials such as copper, stainless steel and cupronickel. The tube expansion, during the flaring phase, allows a perfect contact between the tubes and the fins and as a consequence it assures efficient thermal exchange.

COPPER - Copper tube

STAINLESS STEEL - AISI 316L tube

CURRONICKEL - CuNi10Fe1Mn tube

FINS

The fins, made of aluminium, prevarnished aluminium or copper, are pressed by means of a particular ondulation that increases the thermal exchange between the air and the fin reducing the load losses on the air side and encouraging at the same time the flow of condensation or defrosting water.

The fins can also be made from 316L stainless steel for installations where the thermal exchange is in aggressive environments such as the food sector or exchangers used in salty environments.

The main geometries, achievable according to the chosen material, are reported following below; besides, according to the application chosen by the customer and to the thickness of the requested strap, it will be possible to make a major or minor pitch between the fins.

ALUMINIUM FINS

HYDROPHYLIC ALUMINIUM FINS

PREVARNISHED ALUMINIUM FINS

STEEL FINS 316L

COPPER FINS

PLATES

Thanks to its accurate three-dimensional design and to modern punchers and numerical control bending machines, it is possible to make carpentry and structures of different sizes that can be adapted to any construction requirement of the customer.

GALVANIZED STEEL PLATES

ALLUMINIUM PLATES

COPPER PLATES

BRASS PLATES

STAINLESS STEEL PLATES Aisi 304

plated with protective pvc

Engineering Data

We have customized products for many customers, following are some projects we did before.

We can provide designing data and prodcution drawings.

![]()

We promise we use the design software sold by a well-known European HAVC software company.

Through 8 years of cooperation with them, we have designed, processed and exported dry coolers to various countries all around the world.

All of customers feedback is that the actual cooling performance is almost the same as the theoretical design value.

![]()

![]()

![]()

![]()

Customer feedback photos

Russia epoxy coating project

Thailand chiller project

New Zealand gold fin evaporator for heat pump project

Italy 7mm fan coil unit coil

British Blygold project