Точные заземленные и полированные карбидные стержни с допуском

- Категория: Бруски вольфрама >>>

- Поставщик: Zhuzhou,Lihua,Cemented,Carbide,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.44 $* | 0.55 $* |

| Aug-17-2025 | 0.11 $* | 0.86 $* |

| Jul-17-2025 | 0.61 $* | 0.31 $* |

| Jun-17-2025 | 0.8 $* | 0.90 $* |

| May-17-2025 | 0.72 $* | 0.43 $* |

| Apr-17-2025 | 0.62 $* | 0.57 $* |

| Mar-17-2025 | 0.95 $* | 0.37 $* |

| Feb-17-2025 | 0.71 $* | 0.33 $* |

| Jan-17-2025 | 0.52 $* | 0.73 $* |

Характеристики

Product Description

Tungsten Carbide Round Rods

Applications:

It is suitable for the production of various types electrical machine & electronic progressive dies and punches. And widely used in ceramics, printing machine, plastic, rubber, leather industry and cutting machines, CNC machine, CNC, PCB micro drill bits,etc.

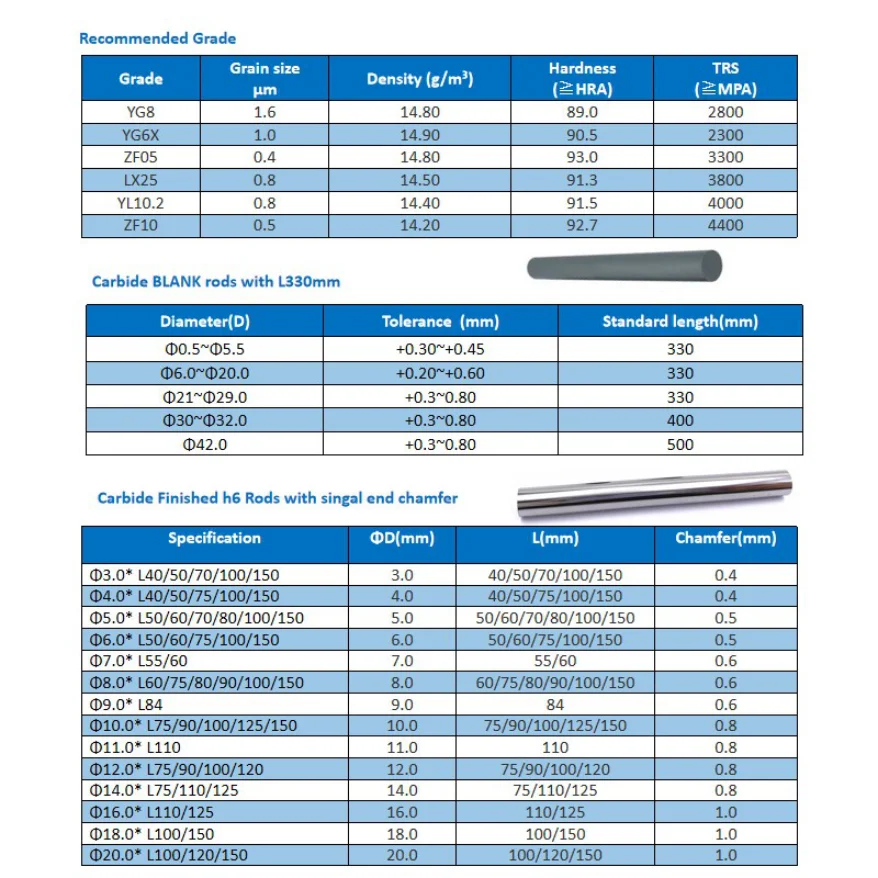

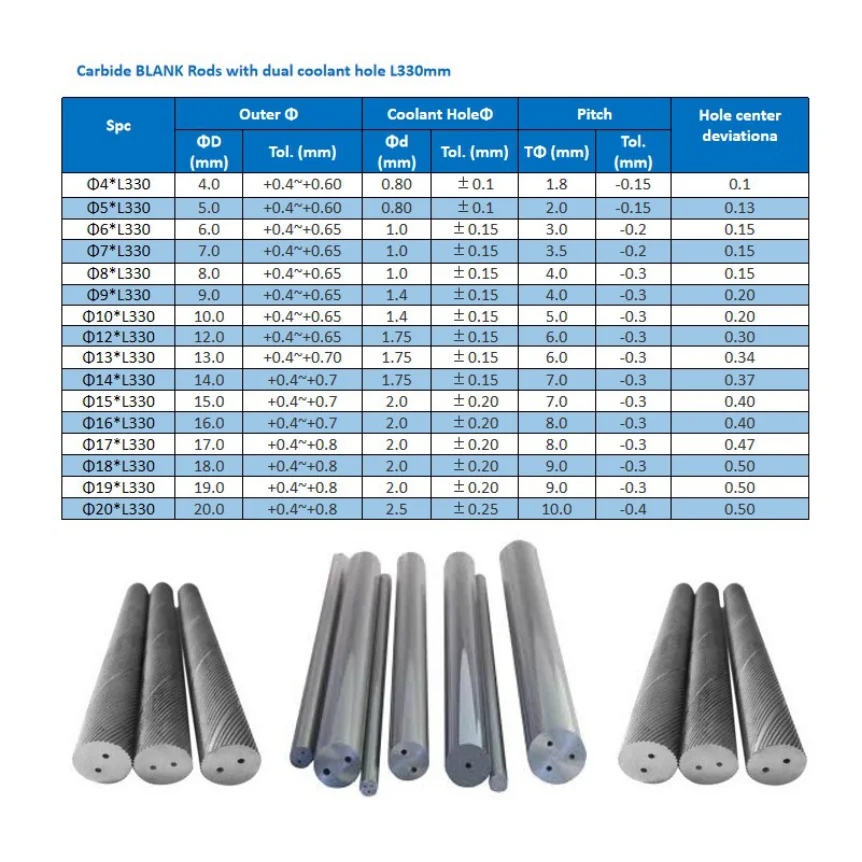

Product Parameters

Details of Tungsten Solid Carbide Rods | ||

Product name | Solid carbide Rod / Bar / Stick | |

OD tolerance | 0.5um | |

Surface fineness | Ra0.025a | |

Sizes | Diamter:Φ0.5-Φ0.35mm,Length:100-330mm(diameter is Φ1.0-Φ6.0mm,lenght can up 700mm) | |

Type | Round(solid,hollow) | |

Grade | YL10.2, K20,K30 ,YL50,YU06A,YU06R,YF06,YH6F,YG11 etc. | |

Material | 100% Tungsten Raw Materials | |

Physical performance | High Precision , hardness,strength, wear resistance . | |

Application | For production various types electrical machine & electronic progressive dies and punches.And ceramics, printing machine, plastic,rubber, leather industry and cutting machines. | |

Non-standard or Tolerance | Can be customized | |

Tungsten Carbide Grade Information | ||||||||

Grade | Density g/cm3 | Hardness HRA(hv) | T.R.S (M Pa) | Performances &applications recommended | ||||

YG6 | 14.9 | 89.5 | 2150 | Good Wear resistance, used for hard wood,processing original wood,aluminum section bar,brass rod and cast iron. | ||||

YG8 | 14.6 | 89 | 2320 | Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. | ||||

YG11 | 14.4 | 87.5 | 2260 | Medium grain, for wear parts and mining tools | ||||

YG15 | 14.1 | 86.5 | 2400 | Medium grain, for mining tools, cold heading and punching dies | ||||

YS2T | 14.45 | 92.5 | 2800 | Fine carbide,high wear resistance,high bending strength,high resistance to bonding, high thermal strength.Machining of refractory alloys, stainless steel and high manganese steel etc.Mainly used for disc cutter and other tools | ||||

YL10.2 | 14.5 | 92.5 | 3400 | Wear resistance and strength comparatively higher,suitable for processing cast iron, non-ferrous metal and non-metalloid materials. | ||||

YNi8 | 14.6 | 88.5 | 1710 | This grade with 8% nickel binder, it has good wear resistance& corrosion resistance performance ,especially used for high pressure environmental , also good for cutting the titanium alloy. | ||||

Related Tools

Our Main products include : Carbide Screwed Boring Bar, Plates, Rods, Sticks, Bushings, TP nozzles, 3D Printer Nozzles, Saw Blades, End Mills & Drill Bits, CNC inserts, Value Seats, Rotary Burrs, wheel cutters, Grits, Customized cutter woodworking tool,V-cutter, Shoes cutter ects. Any kinds of customized carbide products can be made.

Company Information

Company Introduction

Established in 1990, specialized in production carbide products more than 20 years and located in Zhuzhou city which is the hometown of tungsten carbide in China. Our products sold well to worldwide, has been build a long term relationship with our customers from Italy, Portugal,German,Turkey, USA, Mexico, India, Australia, South Africa etc.

We have sophisticated equipments, such as Sintering Furnace, Automatic suppress Machine, Manual Hydraulic Suppress Machine, Ball Mill Machine, Drying Machine, Mixing Machine ect, Our production capacity has up to 15 Tons per month. Customized is welcome, customized sample can be ready in 3-5 days and 1 day can deliver for stocks.

Strictly QC

We have a professional QC team follow to the System of ISO9001:2008, Covering the Raw Materials Incoming, Production Processes,Finished Products and Packaging to ensure high quality products output.

Our Exhibition&Qualifications

Packing&Shipping

We normally will dispatch your order within 2-10 working days depends on stock level, as soon as the

order is shipped. We will list the tracking number on your order details page. If there is any problem regarding to the shipping,

please feel free to contact us.

Below shows the estimate delivery time for different courier:

TNT: 8-10 working days

DHL: 5-7 working days

FedEx: 7 to 10 working days

UPS: 7 to 10 working days

EMS: 10-14 working days

order is shipped. We will list the tracking number on your order details page. If there is any problem regarding to the shipping,

please feel free to contact us.

Below shows the estimate delivery time for different courier:

TNT: 8-10 working days

DHL: 5-7 working days

FedEx: 7 to 10 working days

UPS: 7 to 10 working days

EMS: 10-14 working days

Payment

Less than or equal to $1000: 100% in advance via Paypal ,or Western Union

Over $1000 : 30% T/T deposit , Balance before shipment .

Over $1000 : 30% T/T deposit , Balance before shipment .

Contact

Foreign Sales Manager : Coco Su

Mobile/WhatsApp:+86 13973352165

Skype : Carbide tools

QQ: 1638174610/1007161690

WeChat: cocosd79

Email: coco AT lihuacarbide.com /hongda AT lihuacarbide.com

Website: www.hdlihuacarbide.com

Factory Add: Building B-11,E-commerce Industrial Park ,Xinma South Road ,Tianyuan Zone ,Zhuzhou City ,Hunan Provice ,China 412000

Mobile/WhatsApp:+86 13973352165

Skype : Carbide tools

QQ: 1638174610/1007161690

WeChat: cocosd79

Email: coco AT lihuacarbide.com /hongda AT lihuacarbide.com

Website: www.hdlihuacarbide.com

Factory Add: Building B-11,E-commerce Industrial Park ,Xinma South Road ,Tianyuan Zone ,Zhuzhou City ,Hunan Provice ,China 412000