Автоматический сварочный аппарат для труб шпуля предварительной сборки с источником питания

- Категория: Трубосварочный станок >>>

- Поставщик: Wincoo,Engineering,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 23324.98 $* | 24490.80 $* |

| Aug-19-2025 | 23128.47 $* | 24284.78 $* |

| Jul-19-2025 | 19404.29 $* | 20374.59 $* |

| Jun-19-2025 | 22736.97 $* | 23873.86 $* |

| May-19-2025 | 19796.49 $* | 20786.77 $* |

| Apr-19-2025 | 22344.44 $* | 23461.49 $* |

| Mar-19-2025 | 22148.8 $* | 23255.21 $* |

| Feb-19-2025 | 21952.84 $* | 23050.9 $* |

| Jan-19-2025 | 21756.9 $* | 22844.81 $* |

Характеристики

Product Description

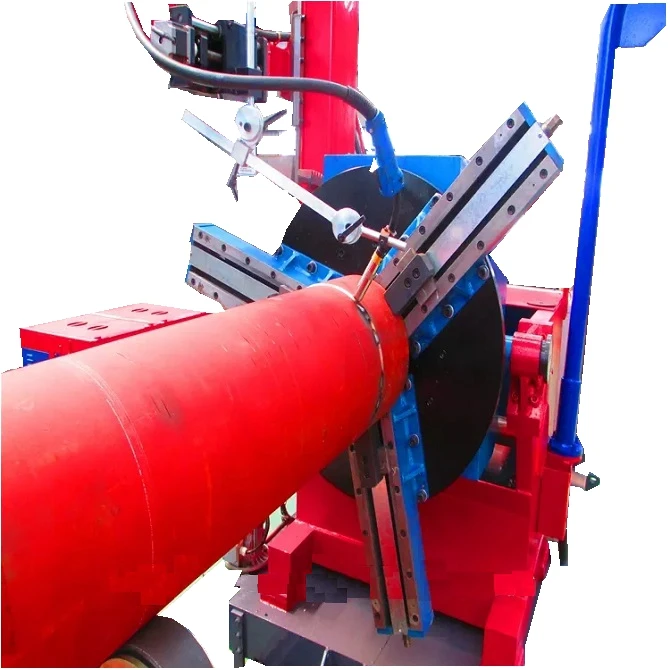

Automatic Pipe Welding Machine for Piping Spool Prefabrication (FCAW/GMAW)

Detailed Images

Model: PFAWM-16Ab/ 24Ab/32Ab/40Ab/48Ab/60Ab

Performance features:

1.On-line Performance: Excellent (Designed completely as per the on-line equipment of the production line)

2.Application: extremely broad (pipe and cover welding of various structures in various industries).

3. Welding Capacity: Excellent (250-350 inch/day, which is 4 times higher than the manual welding)

4.Operability: Good (applicable and easy to operate even if you are a new user)

5. Surface finishing: Excellent (the welding gun will be positioned in the optimum position always)

6.Welding qualification rate: 98% min (without re-working for the skilled operator).

7. Driving Reliability: Good (driven by frictional force, however, it is required to set essential balance weight to offset large

bending moment caused by elbows for large diameter pipe, or providing a chain tensioner to improve the reliability of the

driving).

1.On-line Performance: Excellent (Designed completely as per the on-line equipment of the production line)

2.Application: extremely broad (pipe and cover welding of various structures in various industries).

3. Welding Capacity: Excellent (250-350 inch/day, which is 4 times higher than the manual welding)

4.Operability: Good (applicable and easy to operate even if you are a new user)

5. Surface finishing: Excellent (the welding gun will be positioned in the optimum position always)

6.Welding qualification rate: 98% min (without re-working for the skilled operator).

7. Driving Reliability: Good (driven by frictional force, however, it is required to set essential balance weight to offset large

bending moment caused by elbows for large diameter pipe, or providing a chain tensioner to improve the reliability of the

driving).

Technique parameters

1.Pipe diameter applicable: DN50-400mm (φ60-426mm) / DN100-600 (φ114-630mm)/ DN200-800mm (φ219-830mm); DN400-1000 (φ406-1016);DN600-1200 (φ610-1219); DN800-1500 (φ813-1524) Or custom made acc to requirements

2. Pipe wall thickness applicable: 3-30MM (or as per request)

3. Materials applicable: carbon steel, alloy steel, stainless steel and cryogenic steel

4. Welding line applicable: various butt welding seams of spool pieces such as pipe-pipe, pipe-elbow, pipe-flange, flange-flange and flange-elbow, etc (a fake pipe transition connection shall be applied if necessary).

5. Driving System: driven by two line rubber roller and reducer

6. Clamping system: clamping arm move up & down electrically and clamps by screw

7.Bracket System: Separate type of trolley matching for welding equipments, which may be adjusted along the track according to the length of the pipe

8. Counterweight System: no Counterweight

9. Speed regulation Mode: VF stepless speed control system

10. Adjustment Mode: electric cross regulator

11. Oscillating system: a product of our patented technology, step motor driving and digital displaying oscillating width adjusting.

12. Control system: a product of our patented technology, PLC control

13.Welding procedure: FCAW/GMAW (To be done root pass, filling & final welding)

2. Pipe wall thickness applicable: 3-30MM (or as per request)

3. Materials applicable: carbon steel, alloy steel, stainless steel and cryogenic steel

4. Welding line applicable: various butt welding seams of spool pieces such as pipe-pipe, pipe-elbow, pipe-flange, flange-flange and flange-elbow, etc (a fake pipe transition connection shall be applied if necessary).

5. Driving System: driven by two line rubber roller and reducer

6. Clamping system: clamping arm move up & down electrically and clamps by screw

7.Bracket System: Separate type of trolley matching for welding equipments, which may be adjusted along the track according to the length of the pipe

8. Counterweight System: no Counterweight

9. Speed regulation Mode: VF stepless speed control system

10. Adjustment Mode: electric cross regulator

11. Oscillating system: a product of our patented technology, step motor driving and digital displaying oscillating width adjusting.

12. Control system: a product of our patented technology, PLC control

13.Welding procedure: FCAW/GMAW (To be done root pass, filling & final welding)

Packing&Shipping

We will provide professional export packaging and choose the appropriate mode of transportation, or we can follow the requirements of customers.

After Sales Service

After sale service

Professional technical support and product quality assurance.

Company Introduction

Wincoo Engineering Co., Ltd (WINCOO) is engaged in bringing the most suitable solutions/equipments for client, fabricators, EPC/C companies on pipe fabrication, tank construction, pipeline construction,industrial production lines, clean energy project and other industrial field.

Our Services & Strength

We have ability of providing workable solutions to support clients to be awarded with shorter project execution time, fewer man-hour cost and higher efficiency construction/fabrication method and better quality during phase of project bidding.

Based client’s facility/site space availability, we are able to study/design and present matched configurations on project

schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.

To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.

Based client’s facility/site space availability, we are able to study/design and present matched configurations on project

schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.

To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.

Похожие товары

Аппарат для электросварки, 20-315 мм

US $945.00

Аппарат для электросварки

US $1075

SWT-V355/90 ч, 355 мм

US $3500