Двойные Конические Винты для экструзии

- Категория: Запасные части для станков для резины и пластика >>>

- Поставщик: Zhoushan,Qunying,Plastic,Machinery,Manufactory

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 3749.77 $* | 3936.10 $* |

| Aug-19-2025 | 3717.2 $* | 3903.36 $* |

| Jul-19-2025 | 3119.28 $* | 3275.9 $* |

| Jun-19-2025 | 3654.12 $* | 3837.3 $* |

| May-19-2025 | 3182.32 $* | 3341.27 $* |

| Apr-19-2025 | 3591.34 $* | 3771.16 $* |

| Mar-19-2025 | 3560.88 $* | 3738.45 $* |

| Feb-19-2025 | 3528.26 $* | 3704.13 $* |

| Jan-19-2025 | 3497.94 $* | 3672.80 $* |

Характеристики

Qunying is one of the best machinery supplier in China. We cooperate with many machine factories. Waiting for your cooperate with us,you best choice!

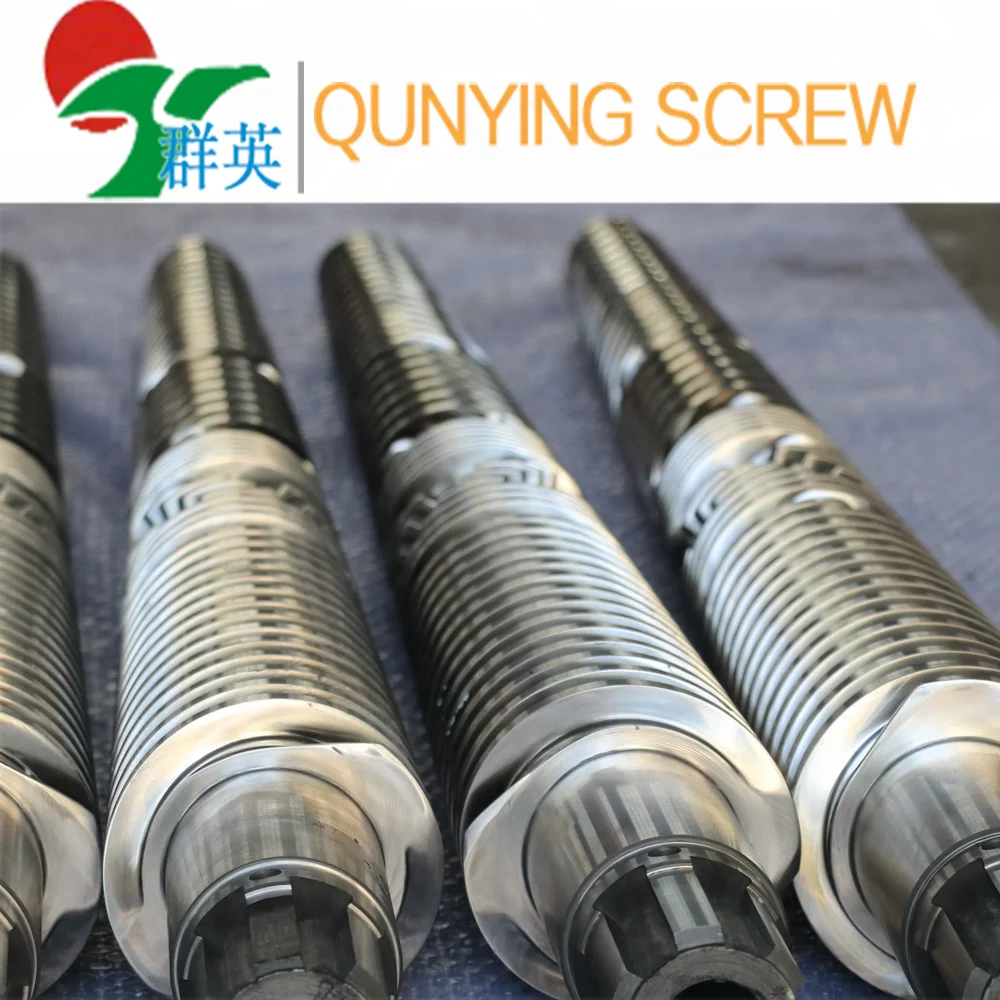

For good plasticizing effect,we have different designs of screw and barrel for injection machine to meet customer's demand.Our factory manufactures with high-quality material, applying the method of hardening and tempering and nitriding, thus it enjoys the characteristics of long working life, wear resistance, and anti corrosion. Besides, the technique of hard alloy spraying or chrome plating can be used on the working surface of screw, which will make it have better using effectiveness.

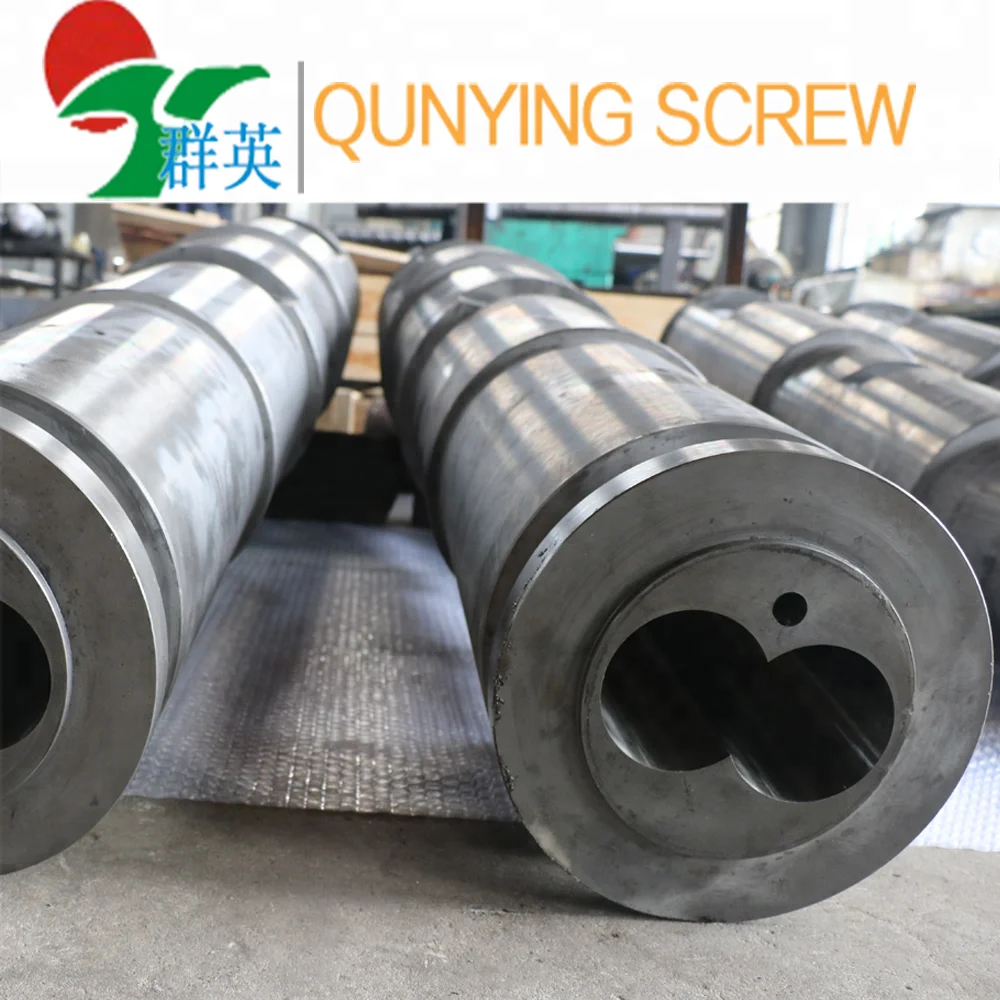

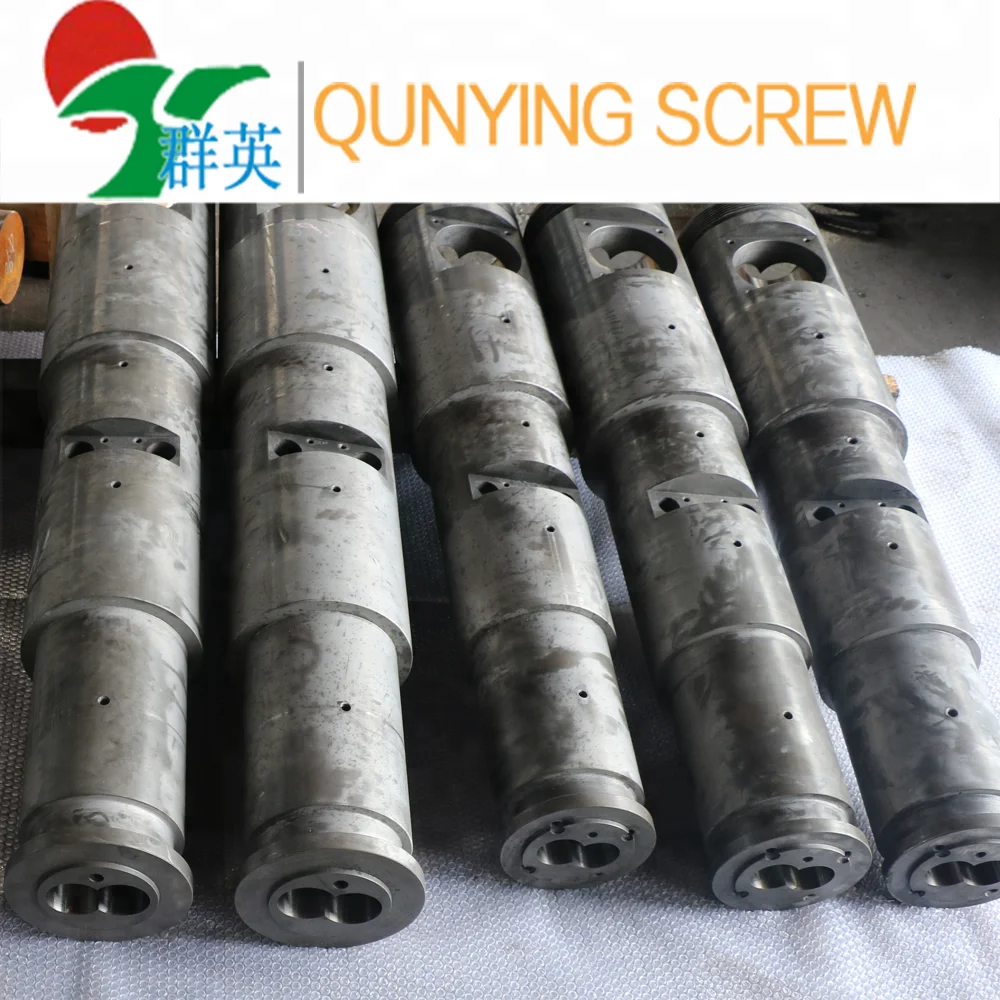

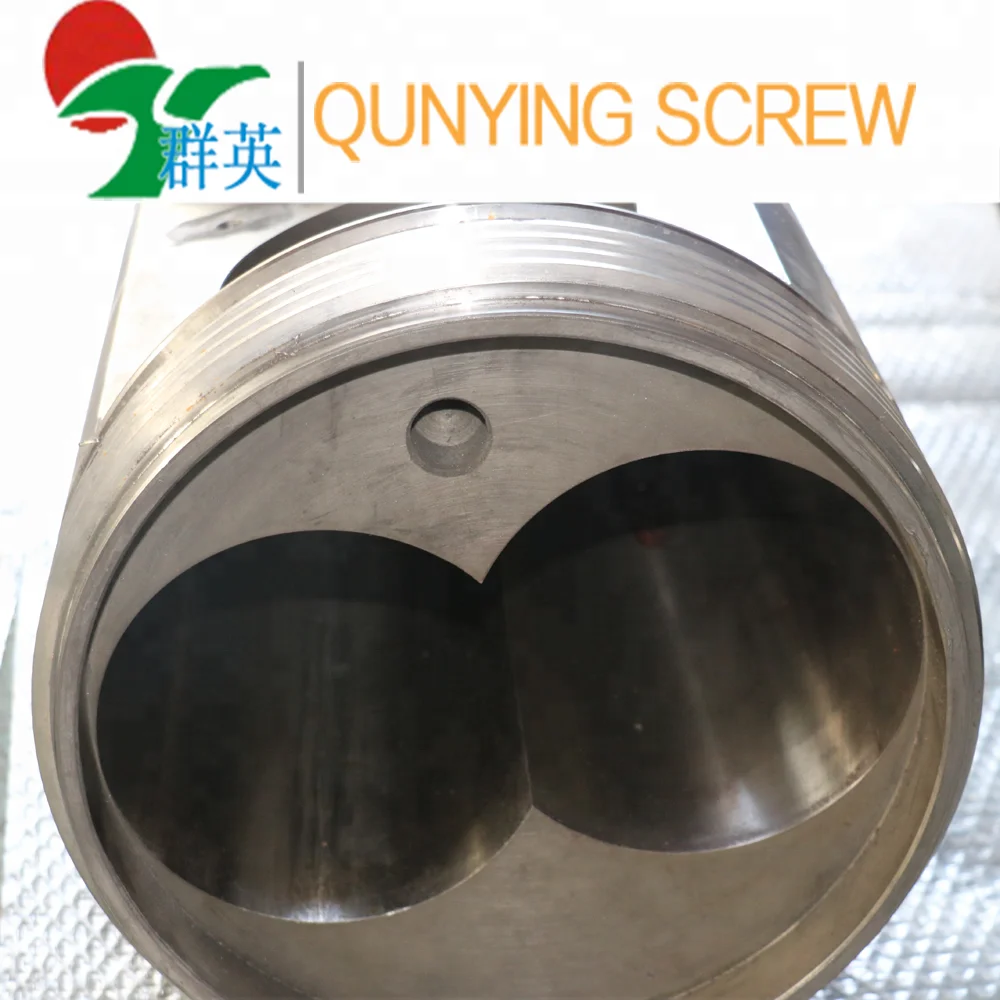

Extrusion Conical Twin Screw Barrel:

45/90; 51/105; 55/120; 65/132; 80/156; 92/188

Product Name | WPC extrusion conical twin screws |

Base Material (steel) | 38 CrMoAlA(JIS SACM645); 42 CrMo(AISI 4140); Cr12MoV(JIS SKD-11); 4Cr5MoSiV1(JIS SKD-61) |

Process ( hot treatment) | Nitriding treatment 72 hours Bimetallic treatment |

Hardness after hardening and tempering | HB260-320 |

Nitrided Hardness | HV900-1000 |

Nitrided Case Depth | 0.5 - 0.8 mm |

Nitrided Brittleness | Less than Grade 2 |

Surface Roughness | Ra 0.4 |

Screw Straightness | 0.015 mm |

Bimetallic Hardness | HRC 53-65 |

Bimetallic Depth | 0.8-2.0mm for screw ; 1~3mm for barrel |

Chromium plating Depth | 0.05~0.10mm |

Hardess of surface chromium-plating after Nitriding | HV≥950HV |

For good plasticizing effect, we have different designs of screw and barrel for extruder or injection to meet customer's demand.Our factory manufactures with high-quality material, applying the method of hardening and tempering and nitriding, thus it enjoys the characteristics of long working life, wear resistance, and anti corrosion. Besides, the technique of hard alloy spraying or chrome plating can be used on the working surface of screw, which will make it have better using effectiveness. We can produce for Haitian, Chenhsong, Demag, Engle, Nigrobossi, KMD, NPM, BOY, HUSKY, Nippon Steel, Toshiba, Nissei, Mitsubishi, CINCINNATI, BATTENFELD, KRUSSMAFFEI, BAUSANO, WEBER, AMUT and so on.

Barrel inspection

Eech barrel must inspect before shipping

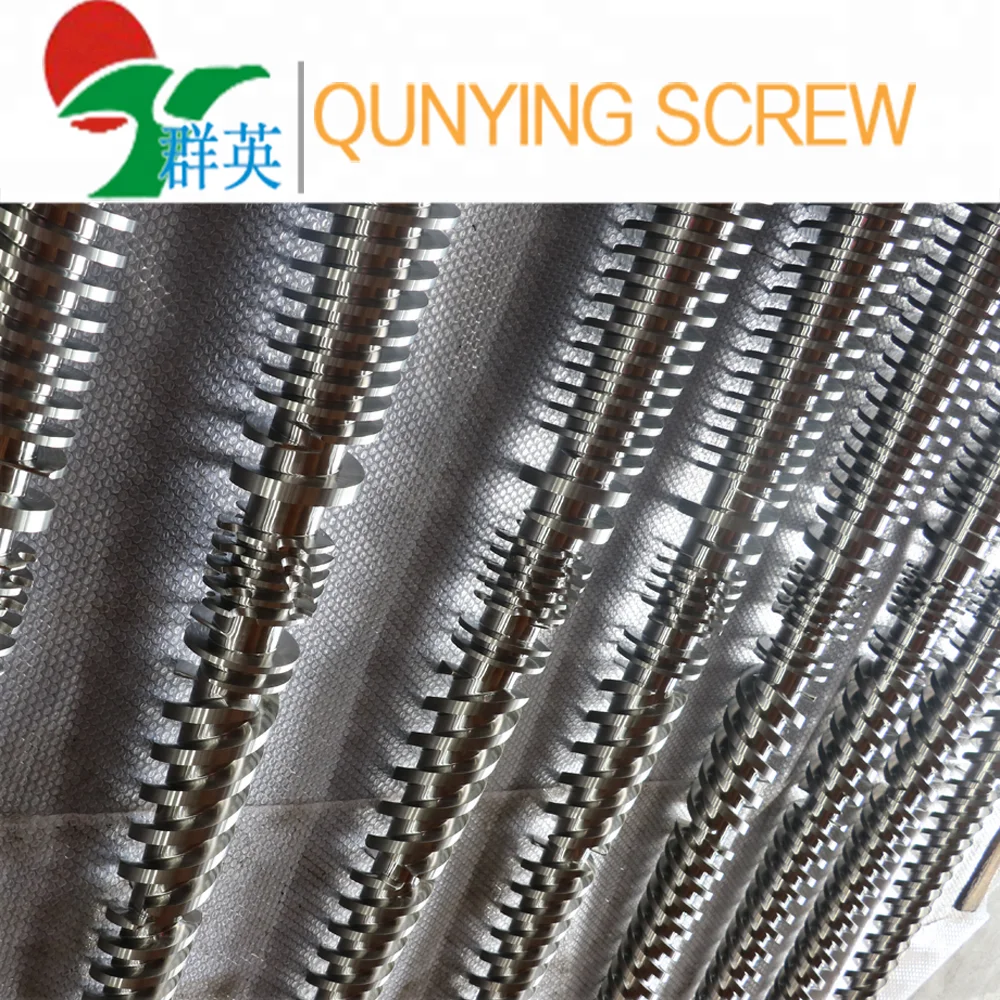

Screw surface hardness

Each screw, we must test the hardness before shipping

Screw thread size

Strict inspection to ensure product quality

CNC

Workshop

Our Workshop, we are in zhoushan city, zhejiang province

Nitriding

Our nitriding treatment

Bimetallic

Our bimetallic treatment

Packing Details : Packing, 1 set / 1 box

Delivery Details : 25-30 days after order confirming

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 25-30 days after the drawings confirm.

Q: Do you design?

A: Yes, we can design according to different requirement. Like PC, PVC is not the same designing.

Q: Can you do the oversea service?

A: Yes, we can go to your company to do technical support and measuring.

How to find us? 24 hours on line!