Автоматическая машина для резки кожи с ЧПУ цена на

- Категория: Оборудование для производства кожи >>>

- Поставщик: Jinan,Yizhou,Laser,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 20825.61 $* | 21866.39 $* |

| Aug-18-2025 | 20650.29 $* | 21683.51 $* |

| Jul-18-2025 | 17325.43 $* | 18191.58 $* |

| Jun-18-2025 | 20300.24 $* | 21315.11 $* |

| May-18-2025 | 17675.23 $* | 18559.64 $* |

| Apr-18-2025 | 19950.61 $* | 20948.67 $* |

| Mar-18-2025 | 19775.54 $* | 20764.55 $* |

| Feb-18-2025 | 19600.88 $* | 20580.14 $* |

| Jan-18-2025 | 19425.44 $* | 20396.93 $* |

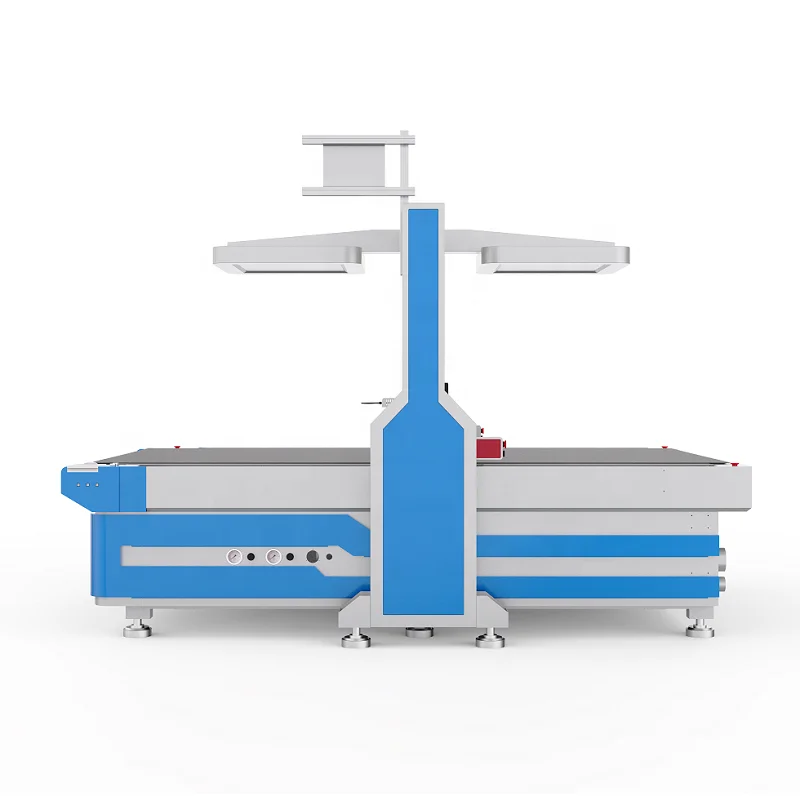

Характеристики

Product Application

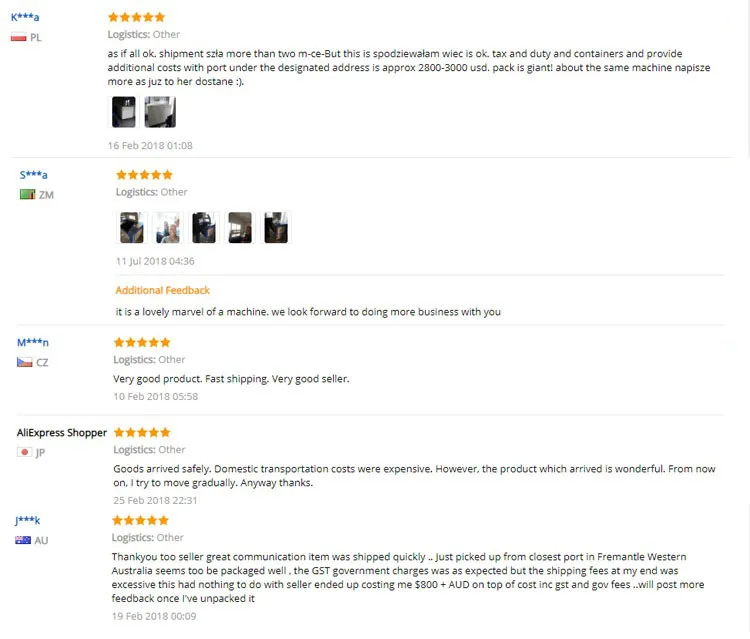

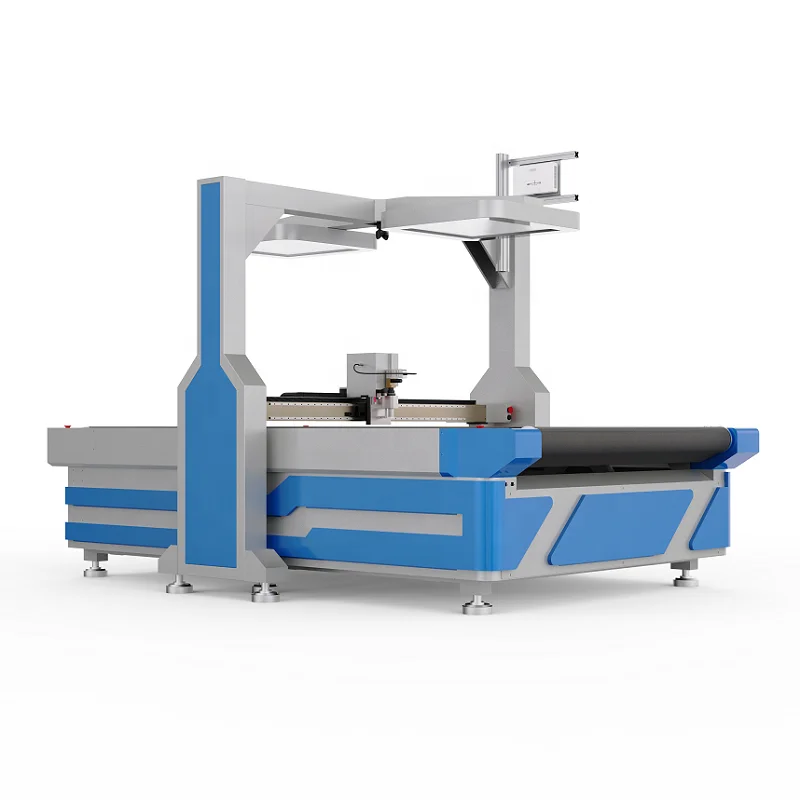

This cnc leather cutting machine is applicable for genuine leather,rexine leather, artificial leather,like calf,cowhide,skin,goat etc.As we know,Most of genuine leather has defect,like scar,pinhole,crack etc poor area. so before cutting,we must mark the defect.

This cnc leather cutting machine is widely used in shoes making industry,leather belt industry,furniture industry,automotive interior industry,bags industry.

11. The platform detection device regulates the knife pressure automatically, enabling a level platform and perfect cutting.

2. Imported linear guide and servo motor ensure high precision and fast working speed.

3. The high precision yizhou CNC oscillating knife leather cutting machine can induce draft separately and easily cuts small pieces.

4. The anti-collision and the built-in auto-sensing devices ensure the security of yizhou cnc oscillating knife leather cutting machine.

5. High efficiency can be realized without making a high-cost knife model.

6. The high precision YIZHOU CNC oscillating knife leather cutting machine is designed for production with small quantities and can save on costs while maintaining speed and accuracy.

7. Cutting by knife, no pollution gases.

8. Patent product, stable performance, safety and stability, users in wide range.

9. It can equipped with different tools to meet a variety of needs.

CLICK FOR MORE INFORMATION!!!!

Model | Y1625 |

Working size | X Axis 1600*2500mm Y axis |

Air pump power | 7.5KW/9KW/11KW |

Head quantity | Single or Double head for optional |

Max. cutting thickness | 0-50mm |

Knife flute length | 0-30mm |

Knife total length | 0-50mm |

Cutting speed | 0-1500 mm/s |

Knife type | EOT /POT optional |

Lubrication | manual or automatic |

Air compressor | bigger non-stop with SOL Starter |

Characteristic | Computer operation,data transmission fast |

Motor and driver | Panasonic/YASKAWA Servo motor and Driver |

Material fixing method | Intelligent divisional vacuum absorption-whole cast aluminum 42.5mm thickness flatbed fixed whole cast iron aluminum vacuum table. |

Vacuum type | both manual and automatic(only we have this patent. sometimes operator not in front of machine, after cutting, still need vacuum working, or materials position or shape move. ) |

Safety protector | four direction red light protector sensor on both Y axis. |

Machine resolution | 0.01mm |

Software resolution | 0.01mm |

Transmission | HIWIN/PMI Linear guide and rack gears |

Software program | HP-GL and GP-GL drive language |

Control system | TROCEN TC6828 PLUS USB offline on machine panel, or connect to machine, using computer control |

Voltage | vacuum pump 380v three phase machine220v single phase |

Air pump voltage | AC380V±38V\\50HZ |

Language | Chinese/English |

Machine packing size | 3500*2250*1150mm |

Weight | 1500KGS |

Gurantee | 12months |

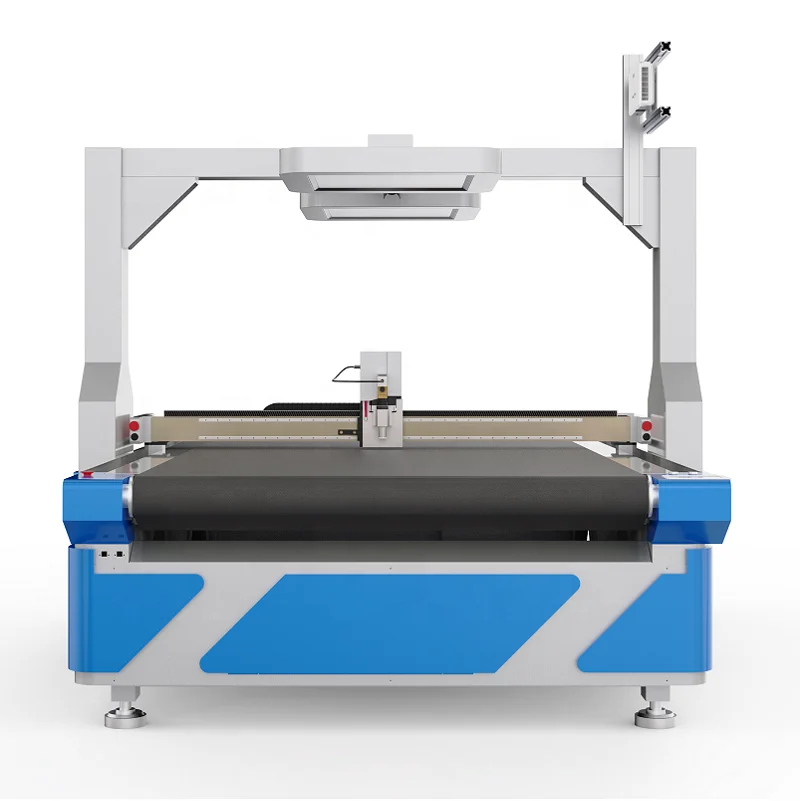

About Machine Advantages

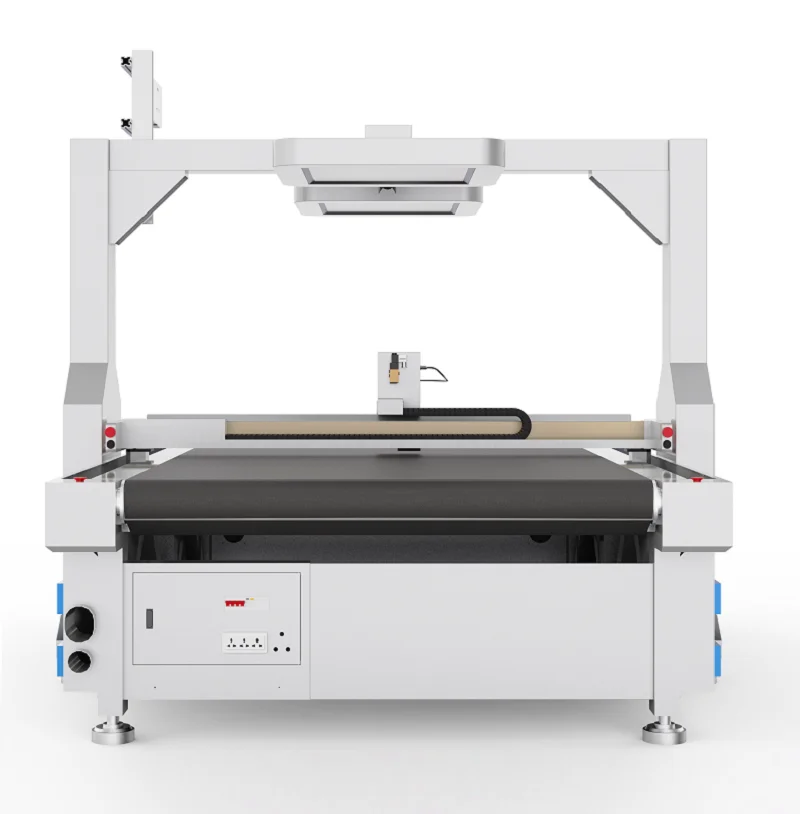

2. Vacuum with Silencer,low noise to protect operator ear and environment.

3. Linear rail and rack gears with Lubrication,easy maintance.

4.With filter,it can dry air to protect EOT/POT knife.

5.Auto feeding felt on table jointed by liquid glue,also with film to cover it. makes table like one whole Felt.

6.Vacuum with manual and automaticly button to control. when operator not in front of machine, can choose manual control vacuum,always vacuum.

7.EOT/POT knife requency updated to 20000 rpm

8.Y axis have 2*2 red light protector sensor in four directions. Protect operator body and life.

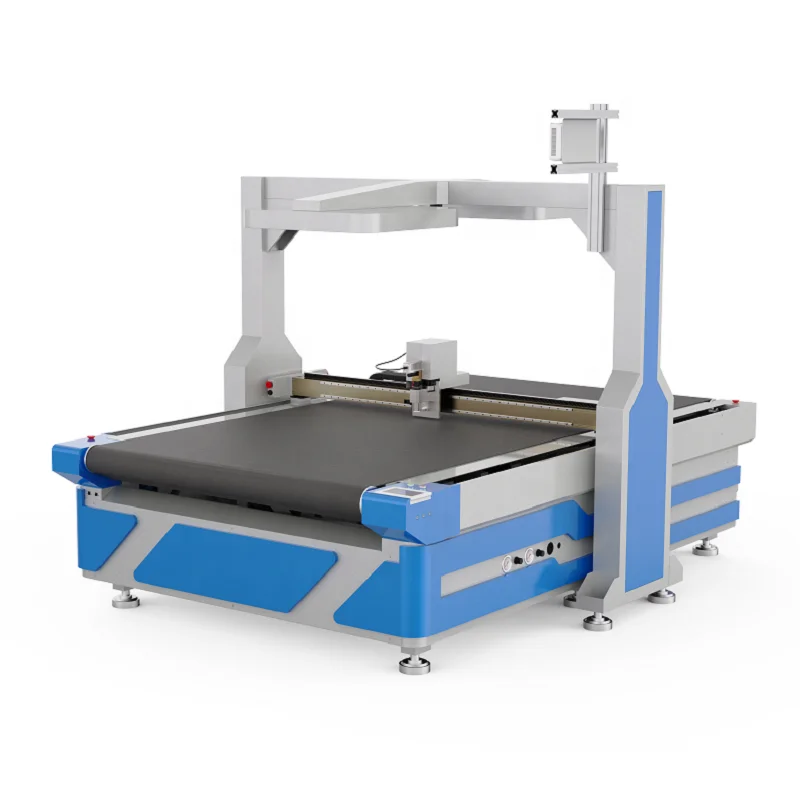

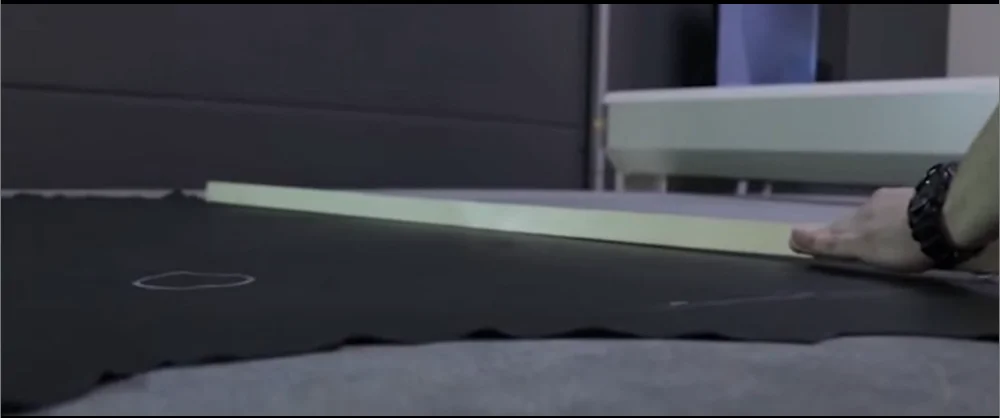

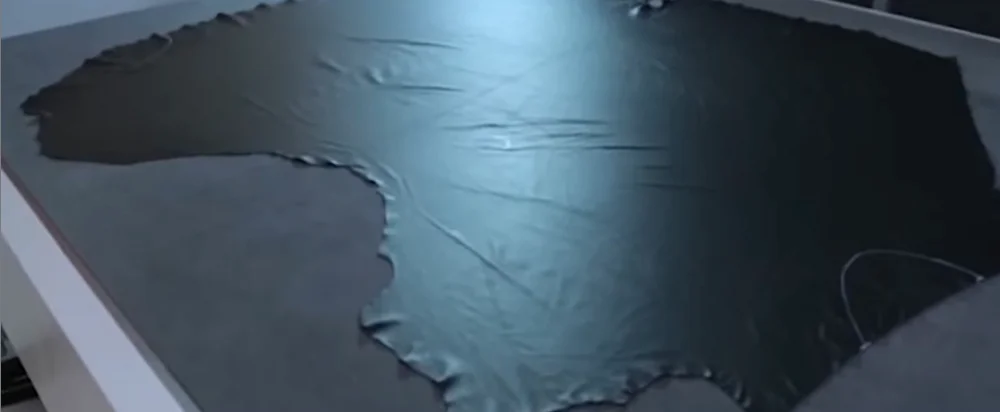

Step one

Put leather on cutting table or machine table.

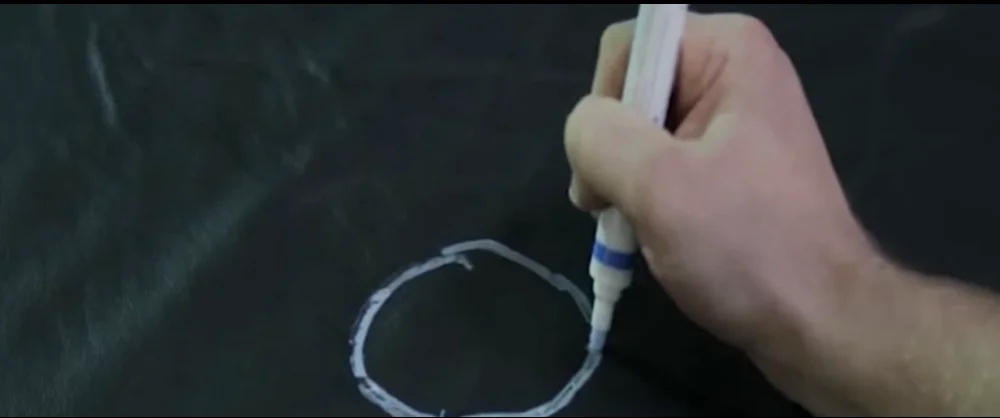

Step Two

Mark the defect or poor area by color pen.

Step Three

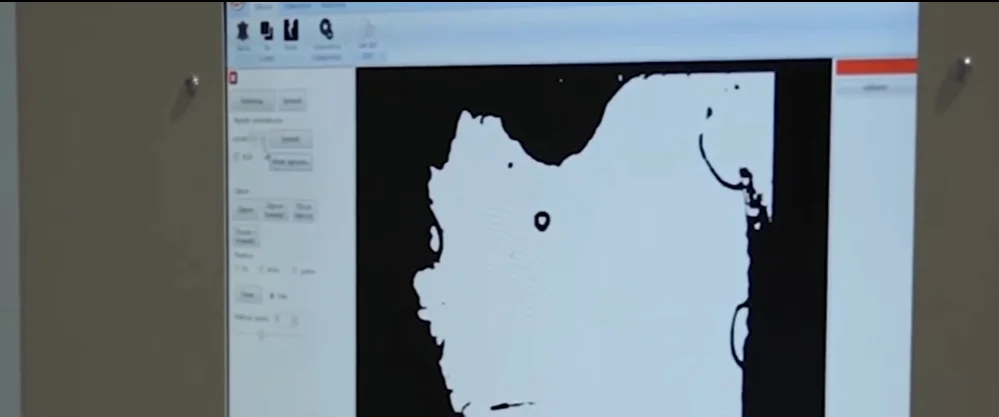

SIR camera connect to computer and hang it in special height,take a photo.

Step three

The camera will take a photo which 1:1 same as real leather piece.

it will shows clear for defect poor area and cutting area.

Step Four

The computer software will automatic extract contour of leather size. 1:1. Error code 0.02mm

Step Five

The software will auto nesting in leather cutting area,auto avoid defect. save materials and cost.

Step Six

Export files from camera software and import the files to cnc leather cutting machine control software.the machine will cutting automatically.