Машина для производства медных

- Категория: Машины для литья металла >>>

- Поставщик: Wuxi,Jintong,Furnace,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.48 $* | 0.69 $* |

| Aug-19-2025 | 0.51 $* | 0.68 $* |

| Jul-19-2025 | 0.49 $* | 0.63 $* |

| Jun-19-2025 | 0.64 $* | 0.99 $* |

| May-19-2025 | 0.21 $* | 0.1 $* |

| Apr-19-2025 | 0.13 $* | 0.89 $* |

| Mar-19-2025 | 0.22 $* | 0.51 $* |

| Feb-19-2025 | 0.28 $* | 0.3 $* |

| Jan-19-2025 | 0.50 $* | 0.67 $* |

Характеристики

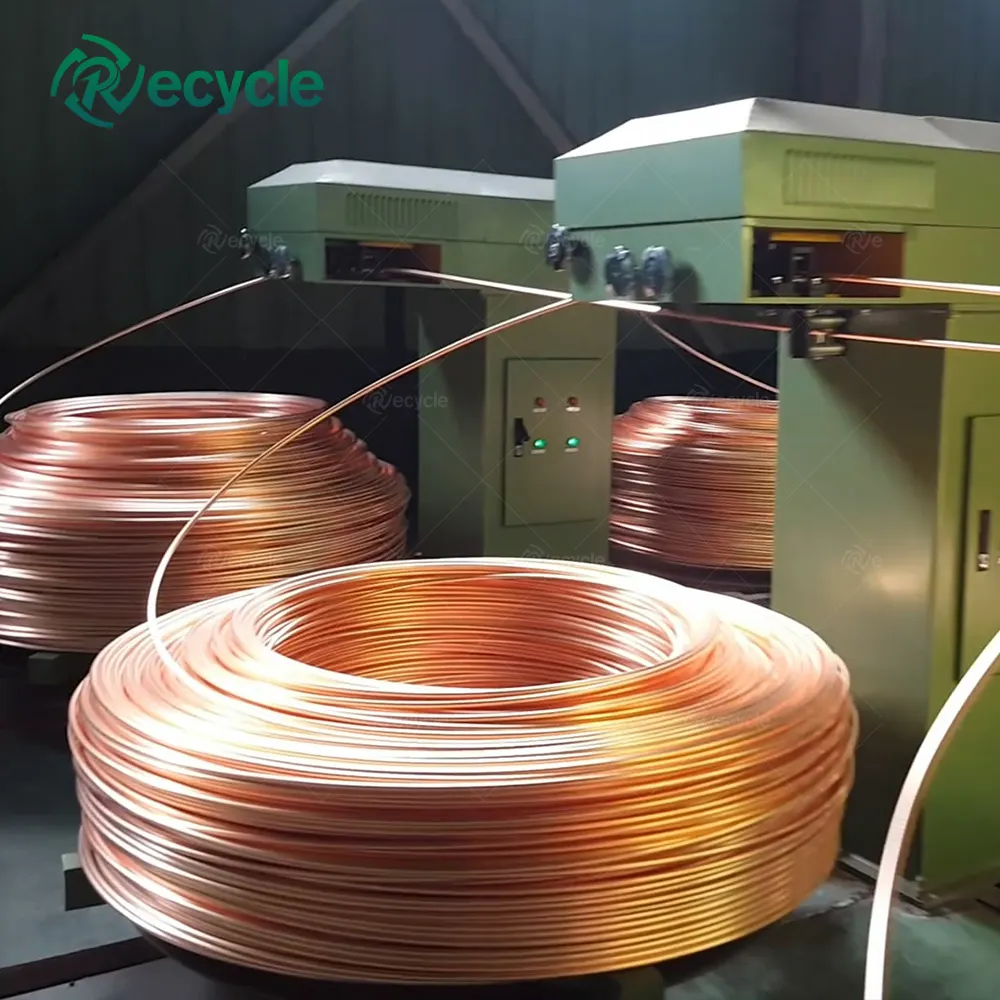

Copper Rod Pipe Tube Making Machine

What do I care about most about this production line?

What to produce: | Oxygen-free copper Tube Copper Pipe(OD:40-50mm ID:20-40mm) |

Why can produce different sizes: | Size to be controlled by moulds, can use different moulds |

What capacity: | 4T-25T/Day/Set |

How to calculate capacity: | 1.5~1.8T / 24 hours / copper tube |

How many rods can get at a time: | 3-6 rods synchronously |

What is the power supply: | Electricity (380V, 50Hz, 3Phase) |

What is the power required: | 75kw~320kw (determined by capacity needed) |

| What is maximum temperature: | 1200 ℃ |

How many countries did you exported: | Turkey, Russia, Uzbekistan, Algeria, Vietnam, Bangladesh, Pakistan, Ukraine , India, Mongolia and so on |

When did your factory establish: | Established since year 2004, first name is Wuxi Xinlian Furnace Factory |

Plant Pictures from Customers

Upcast Oxygen Free Copper Tube Continuous Casting Production Steps:

What are the components of this production line?

1. Up-casting Furnace:

This copper tube production line adopts power frequency induction furnace, which is consist of furnace body, furnace frame and inductor. The outside of the furnace body is steel structure and the inside is consist of fire-clay brick and quartz sand. The inductor is made up of coil, water jacket, iron core and copper ring. The water jacket and coil is cooled by the water. The cooling water is cycling and supplied by the cooling water system. The furnace is controlled by electric control cabinet.

2. Upward Drawing/Traction Machine & Crystallizer:

The drawing mechanism is made up of A.C. servo motor, two groups of drawing rollers and so on.. The following mechanism of liquid level guarantee that the deep of the freezer inserting into the copper liquid is relative stable.The freezer can cool the copper liquid into copper tube by heat exchange. Every freezer can be changed and controlled alone.

3. Copper Tube separation frame & tube guide wheel frame

What is small copper rod continuous casting machine?

This machine can make copper rod with capacity of 100KG~2T per Day.

Other Products

Wuxi Jintong Furnace Co., Ltd. called Wuxi Xinlian Furnace Factory before was established since year 2004, having 10+ years experience in metal melting and metal heat treatment area. Jintong Manufacturing Corp. is specialized in manufacturing induction melting furnace(copper scrap brass scrap, aluminium scrap, zinc scrap, bronze scrap, steel, iron, stainless steel, carbon steel scrap and precious metal like gold or silver). Our furnaces can be applied to many fields such as copper/brass rod/pipe continuous casting, zinc ingot, aluminum rod continuous casting or power resistance.

We sincerely invite you to visit our factory and offer your valuable guidance. Looking forward to cooperating with you.

Our Customers:

Q. What is your MOQ?

A. 1 set.

Q. Your company is a trading firm? or Factory?

A. We are a factory with 10+ years experience in industrial melting feild. We currently have three branches: main frequency furnace production, medium frequency furnace production, component machine production. You are warmly welcomed to visit our factories.

Q. How is your products quality?

A. As a manufacturer, we have our own R&D team. Basing on several years of technical innovation, we have accumulated successful experience in induction heating, temperature holding, fast melting. We've customized so many furnaces with all positive feedbacks.

Q. What kind of material our furnace can melting?

A. Jintong is able to supply a melting production line such as copper/zinc/aluminum melting line.Jintong medium frequency furnace can also melt iron, steel, gold, silver and so on.

Q. I am not so familiar with your machine now. I am not sure I can use it well if I buy it from you.

A. Don't worry about this. With the machine, we will send you a brochure with detailed information of our machine operation. In addition, we will send you videos of machine set up and using. Our engineers are always available for consultation. Engineers can support at your place if it is needed.

How to Contact Us?

Please provide us with following basic information:

What product you want to make?

What kind of raw material do you have? (Pictures are very appreciated)

What capacity do you need, daily, monthy or yearly?

What is the working hours there every day?

Whatsapp/Wechat/Skype: 0086 15906188353

Email: eva at jintongindustry.com

Send your Inquiry Details Below , Click "Send" Now !