Профессиональное производство нержавеющая сталь клей и glatine испаритель восстанавливающий пленочный для

- Категория: Evaporator >>>

- Поставщик: Propellent,(beijing),Energy,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.84 $* | 0.94 $* |

| Aug-15-2025 | 0.66 $* | 0.3 $* |

| Jul-15-2025 | 0.26 $* | 0.93 $* |

| Jun-15-2025 | 0.90 $* | 0.36 $* |

| May-15-2025 | 0.57 $* | 0.91 $* |

| Apr-15-2025 | 0.11 $* | 0.82 $* |

| Mar-15-2025 | 0.45 $* | 0.47 $* |

| Feb-15-2025 | 0.42 $* | 0.34 $* |

| Jan-15-2025 | 0.2 $* | 0.42 $* |

Характеристики

1,As a professional manufacturer, we can offer you high quality products with competitive price , fast delivery and customized service.

2,As a responsible manufacturer, we promise One year lifetime guarantee.

3,As a experienced manufacturer,we can supply the best quality replace parts for some brands to help you save cost.

4,As a active manufacturer, we develop new designs nearly every month. If you were interested in it, it would be my pleasure to offer news to you.

| Material of Plate | Suited Liquid |

| Stainless Steel (AISI304.316 Etc) | Pure Water, Normal Water, Oil for eating, Mineral Oil |

| Ti, Ti-pd | Sea Water, Saline Water, Mineral Water |

| 20Cr, 18Ni, 6Mo (254SMO) | Dilute Sulphuric Acid, Organic Water Solution |

| Ni | High-temp and concentration caustic soda |

| Hastelloy (C276, D205, B2G) | Concentration Sulphuric Acid, Hydrochloric acid, Phosphoric acid |

| Material of Gasket | Operating Temperature ° C | Suited Liquid |

| NBR | -15~+135° C | Water, Sea Water, Mineral Oil, Salinous Water |

| EPDM | -25~+180° C | Hot Water, Steam, Acid, Alkali |

| F26 | -55~+230° C | Acid, Alkali |

| TPF | 0~+160° C | High Concentrated Acid, Alkali, High temperature Oil, Steam |

Standard design

Multi-Effect Evaporation is an important procedure adopted to economize the consumption of energy.

Multi-Effect Evaporators are the instruments in which steam from an outside source is condensed in the heating element of first effect. The boiling temperature at which the first effect operates is high enough so that the evaporated water can serve as the heating medium for second effect. The vapors so formed are then sent to a condenser if it is a double effect evaporator.

The feed for the multi-effect type evaporator is generally transferred from one effect to another. This leads to the ultimate product concentration to reach only in the one effect of evaporator.

Working principle

Channels are formed between the plates and the corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the plate between the channels, and complete counter-current flow is created for highest possible efficiency. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer.

Application

Wastewater treatment, chemical production, Biochemical,sugar purification, starch sugar products, etc.

>>>>>>>>>>>>>>>>>>>>>>>>CONTACT US

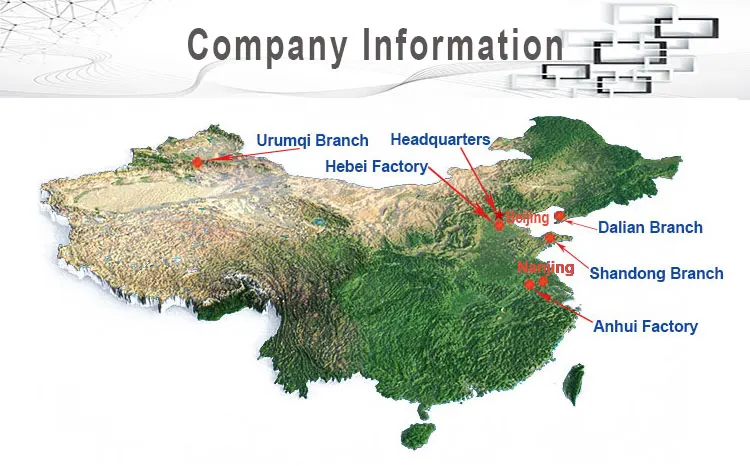

Propellent, composed of several domestic Propellent enterprises, has always been insisting this business philosophy: opening-up and cooperation, mutual improvement with the cooperative partner and growing together with employees.

“Trust us, we can do more” is our enterprise tenet. We devote to provide a heat transfer solution for civil and industrial users in heating, cooling, waste heat recovery. Products we supplied include plate heat exchangers, plate type condensers, air coolers, wide gap plate heat exchangers, welded plate heat exchangers, heat-exchange units, plate type evaporators, air-handling system, water cooling equipment, waste heat recovery integration device, etc. The application scope covers HVAC, chemical, food and beverage, sugar, metallurgy, power, paper, textiles, shipping, and refrigeration, etc.

The superiority of Propellent’s hot and cold exchanging technology comes from its consist high attention to talent cultivation and product research. Propellent values group building and team building pays attention to product performance & quality.

To find more information, you can find on our website: propellentphe.en.alibaba.com

Corresponding certifications can be provided according to the customer's request.

Q1: Why should I choose Propellent?

A: Propellent makes heat exchangers and replacement parts in our own facilities in Hebei and Anhui, giving us complete control of their design, quality, and execution.

Q2: How can I assure the quality of what I want?

A: Related certificates and documents can be provided. Also, pressure test process can be recorded for you to check.

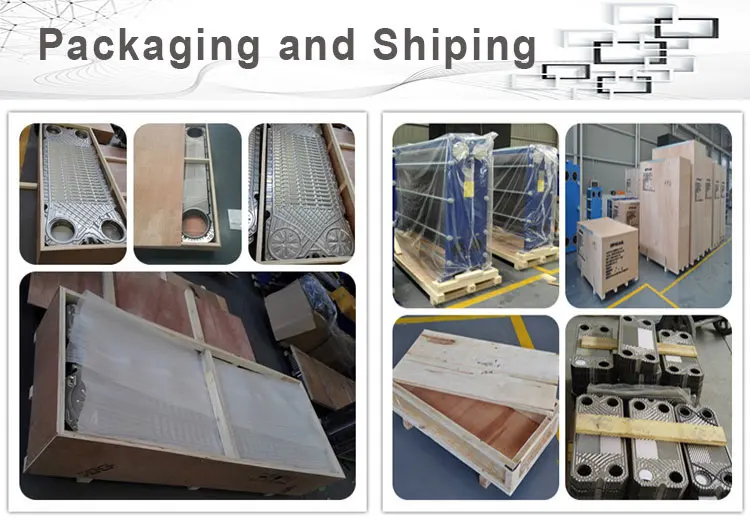

Q3: What is the lead time?

A: Propellent keeps over 100,000pcs of plates and 300,000pcs of gaskets in stock. If there is no available stock, the EXW lead time would be 10~15 days.

Q4: What after-sales services can you provide?

A: If there were any problems with our products, our engineers will serve you 24h per day in many ways, including telephone instruction or video instruction.

Q5: How can I get quotation of what I want?

A: You can

- choose one product and leave a message to us.

- inform us of your technical requirements.

- send us your technical requirements for us to choose the suitable equipment.