Машина для литья под давлением ПЭТ изготовления бутылок с

- Категория: Установка для инжекционного прессования >>>

- Поставщик: Zhangjiagang,Ostar,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 22610.56 $* | 23741.1 $* |

| Aug-16-2025 | 22420.38 $* | 23541.65 $* |

| Jul-16-2025 | 18810.85 $* | 19751.29 $* |

| Jun-16-2025 | 22040.74 $* | 23142.77 $* |

| May-16-2025 | 19190.9 $* | 20150.13 $* |

| Apr-16-2025 | 21660.39 $* | 22743.37 $* |

| Mar-16-2025 | 21470.12 $* | 22544.27 $* |

| Feb-16-2025 | 21280.94 $* | 22344.72 $* |

| Jan-16-2025 | 21090.24 $* | 22145.73 $* |

Характеристики

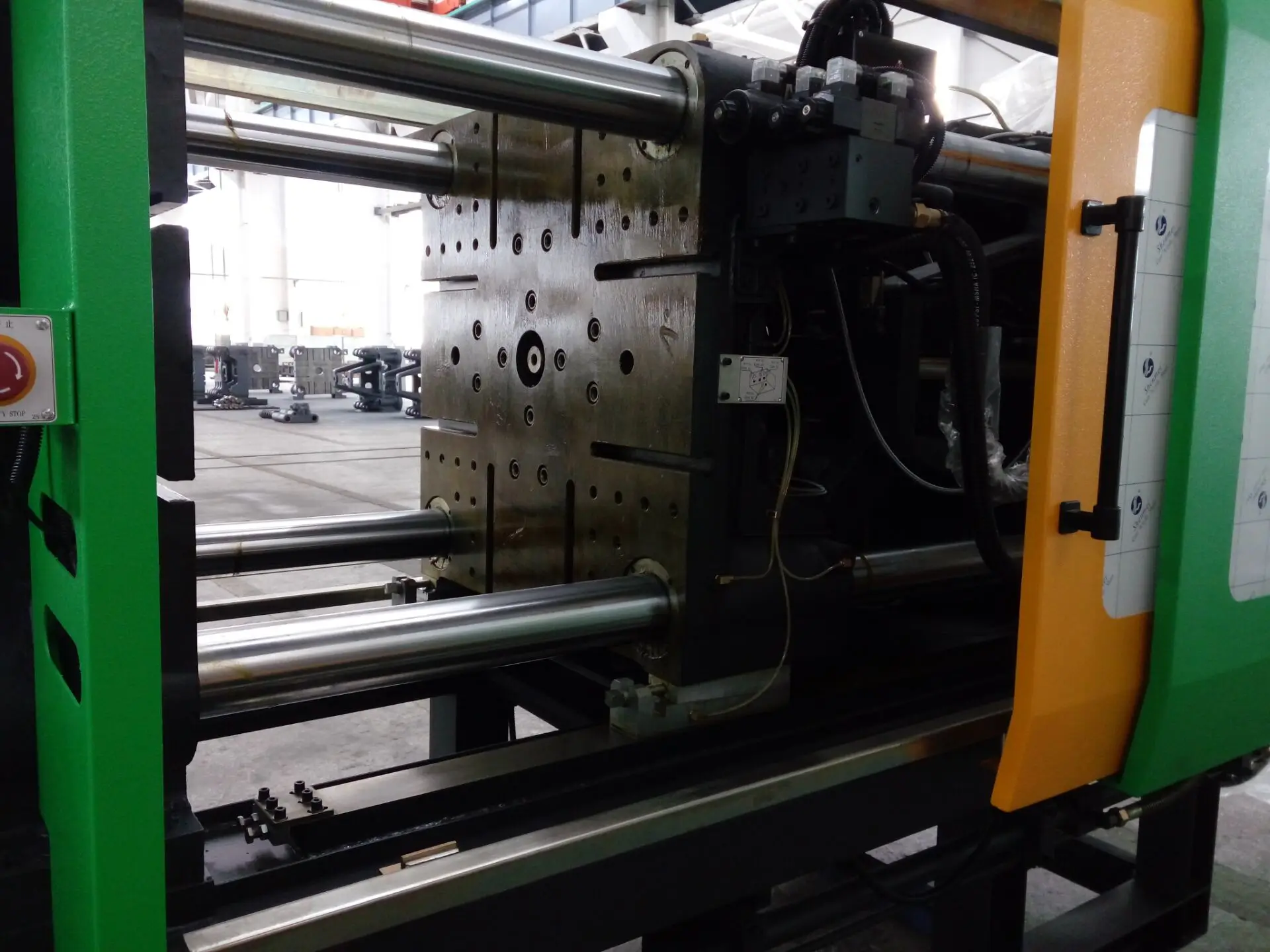

Machine Model | Unit | OSTP2000 | OSTP2300 | OSTP2600 | ||||

Injection Unit | ||||||||

Screw Diameter | mm | 62 | 62 | 72 | ||||

Screw Diameter Ratio | L/D | 24:1 | 24:1 | 24:1 | ||||

Theoretical Shot Weight | cm3 | 814 | 814 | 1300 | ||||

Injection Weight(PET) | g | 830 | 830 | 1320 | ||||

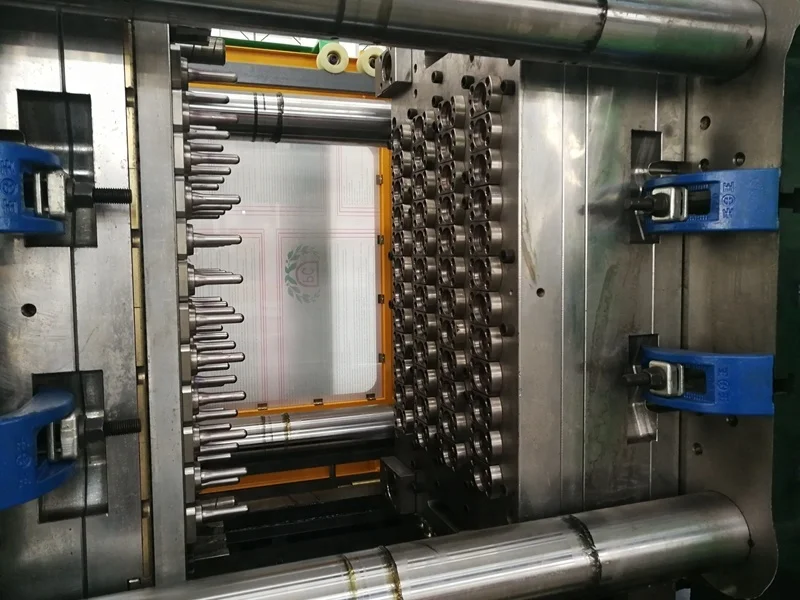

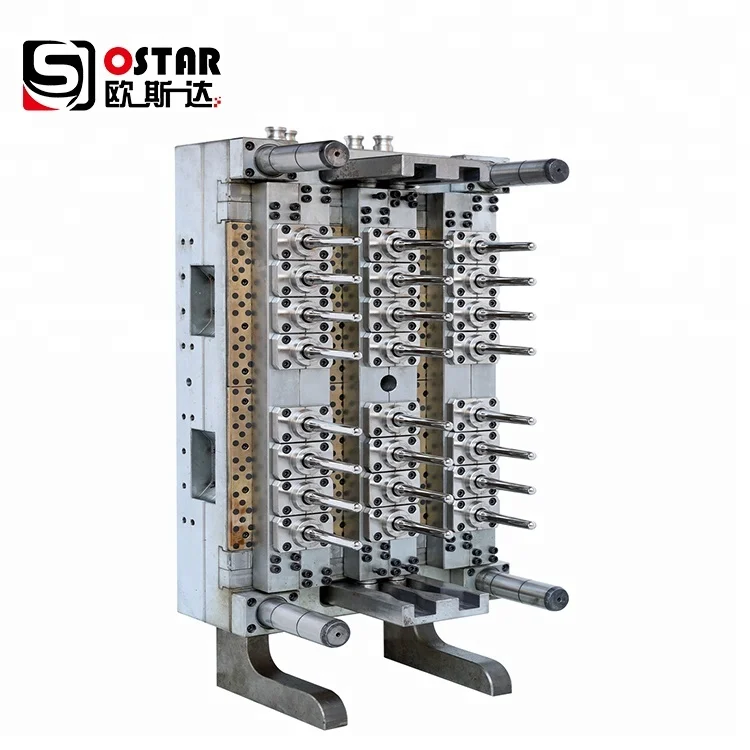

Preform Mold Cavity | Cavity | 16 | 24 | 32 | ||||

Injection Stroke | mm | 270 | 270 | 320 | ||||

Injection Pressure | Mpa | 131 | 131 | 137 | ||||

Clamping Unit | ||||||||

Clamping Force | kN | 2000 | 2300 | 2600 | ||||

Toggle Stroke | mm | 436 | 500 | 560 | ||||

Space Between Tie Bars | mm*mm | 460*460 | 520*520 | 580*580 | ||||

Mold Thickness(Min-Max) | mm | 180-500 | 220-550 | 250-610 | ||||

Ejector Stroke | mm | 140 | 140 | 170 | ||||

Ejection Force | kN | 70 | 102 | 102 | ||||

Others | ||||||||

Max Injection Pressure | Mpa | 16 | 16 | 16 | ||||

Oil Pump Motor Power | kW | 22 | 22 | 30 | ||||

Heater Power | kW | 22.4 | 22.4 | 36.1 | ||||

Machine Size | m*m*m | 6.04*1.46*2.04 | 6.2*1.46*2.16 | 7.1*1.55*2.26 | ||||

Machine Weight | T | 6 | 7.5 | 8.6 | ||||

Ostar Machinery manufacture machines from 70T to 2000T, injection weight from 50g to 10000g, more than 30 different model machines, over 1500sets machine output ability yearly. Due to continually developing innovation and technological improvement, our machines has exported worldwide, with a good reputation all around world.

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer, we supply the factory price with good quality, welcome to visit !

Q2:How about quality control in your factory?

A2: We have a pre-shipment inspection team, every machine need at least automatic running over 72 hours before shipment.

Q3: Is there complete machine include mould and other auxiliary equipment ?

A3: Yes ,what we are provide is the complete A-Z solution line.

Q4: Could you send your engineer to my country, to start the machine?

A4: Surely, we have experience technical engineer for oversea service, they would help you install machine, training your workers.

Q5: Can you help us with the shipment of this machine ?

A5: We have our special shipment company which already cooperate

for long time, we will give you the best price, fast delivery.