Вибрационная машина для очистки песка в

- Категория: Vibrating Screen >>>

- Поставщик: Xinxiang,Gaofu,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 19754.37 $* | 20742.87 $* |

| Aug-19-2025 | 19588.17 $* | 20567.62 $* |

| Jul-19-2025 | 16434.53 $* | 17256.81 $* |

| Jun-19-2025 | 19256.30 $* | 20219.6 $* |

| May-19-2025 | 16766.76 $* | 17604.23 $* |

| Apr-19-2025 | 18924.8 $* | 19870.62 $* |

| Mar-19-2025 | 18758.69 $* | 19696.14 $* |

| Feb-19-2025 | 18592.48 $* | 19522.0 $* |

| Jan-19-2025 | 18426.61 $* | 19347.3 $* |

Характеристики

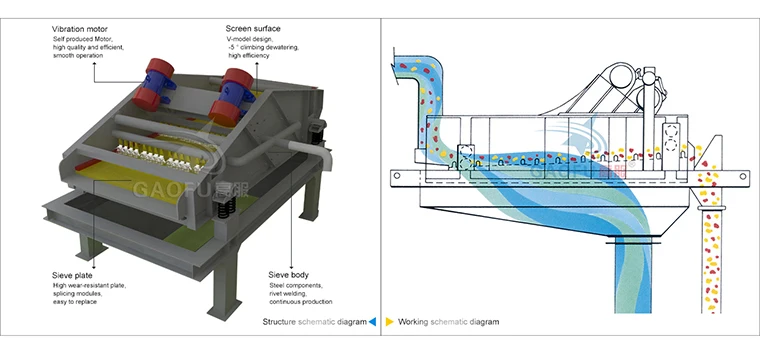

sand dewatering vibrating screen machine in China

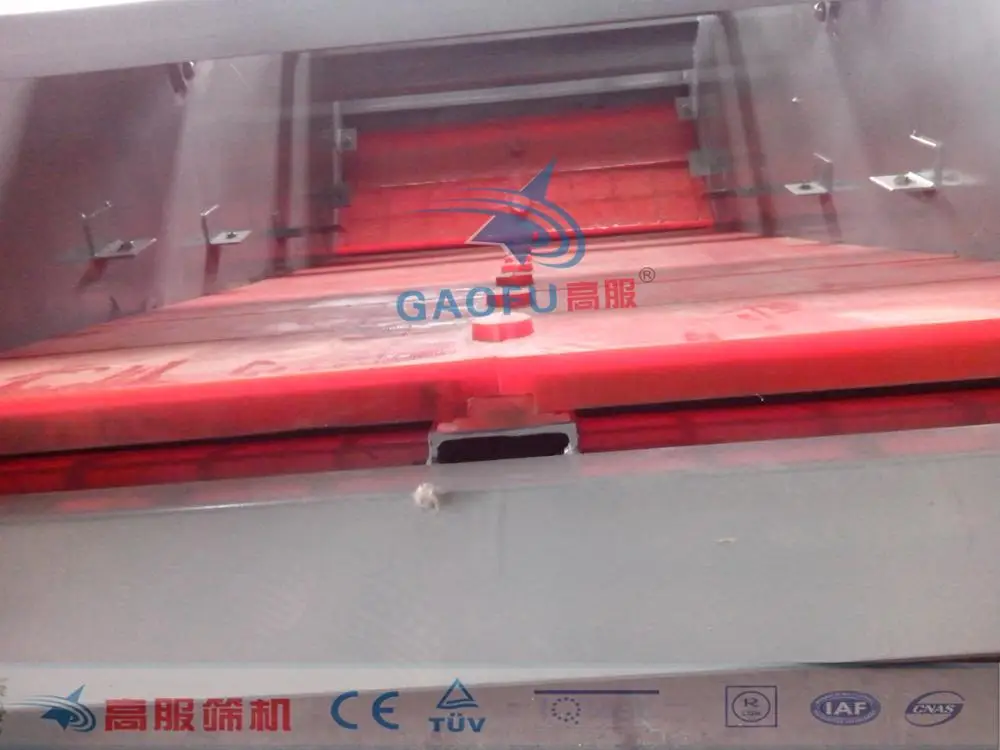

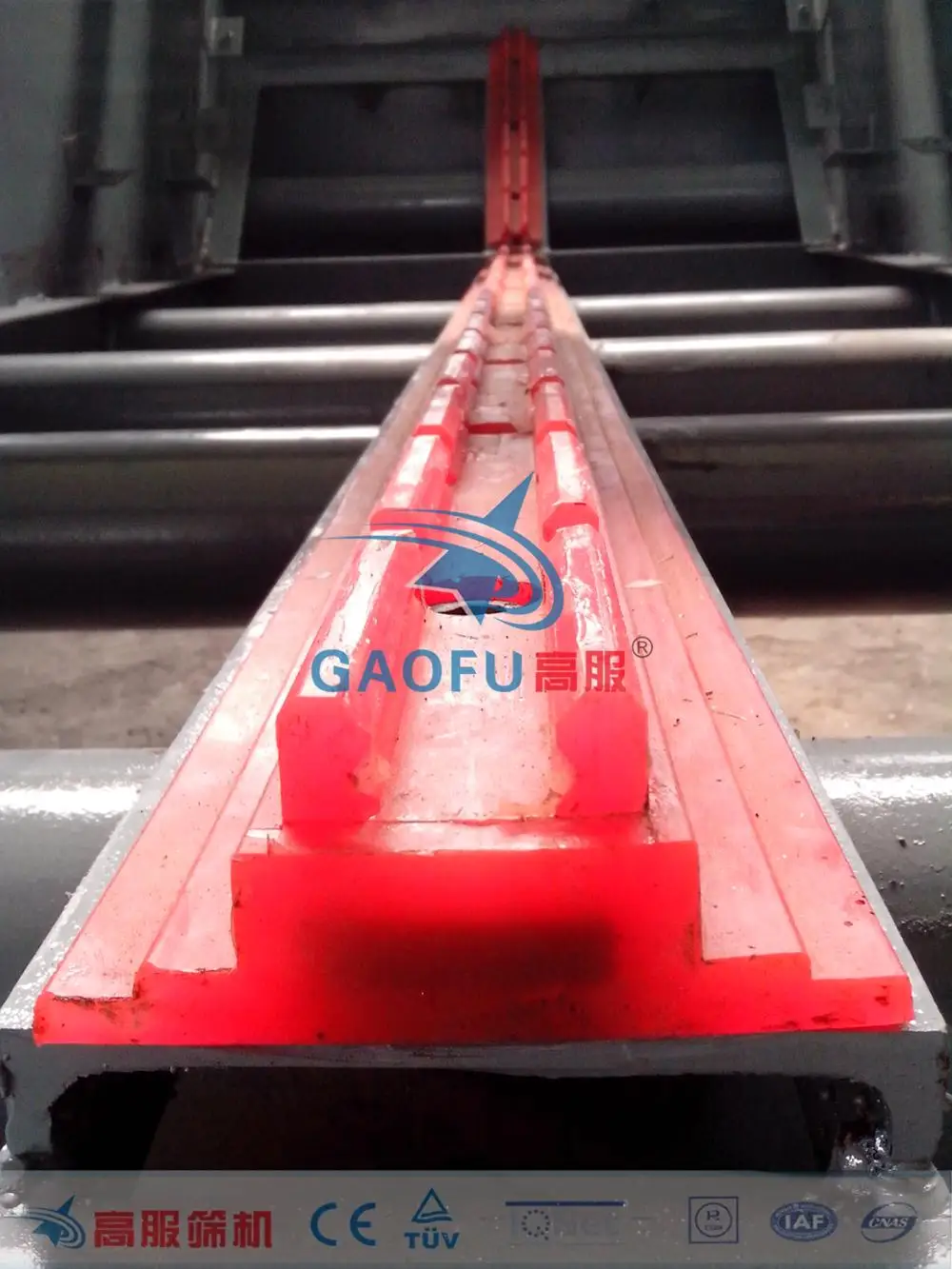

Dewatering screen adopt dual-electrode self-synchronization technology, universal eccentric block, adjustable amplitude vibrator. The machine is combined mainly by the screen box, exciter, support system and motor. The two mutually independent vibrators are respectively driven by the tape coupling to do synchronous reverse operation. The centrifugal force generated by two eccentric masses is superposed along the vibration direction and reversely counteracted, thereby forming a single vibration force along the vibration direction, making the screen box reciprocating linear motion.

Applicatoion of the dewatering vibrating screen

Coal washer: coal, fly ash, clean coal

Dry tailings row: iron tailings, gold tailings, copper tailings, vanadium tailings, lead and zinc tailings, graphite, potassium feldspar dehydration

Washed sand: quartz sand, zircon sand, glass sand, building sand, sand casting, building materials, sand;

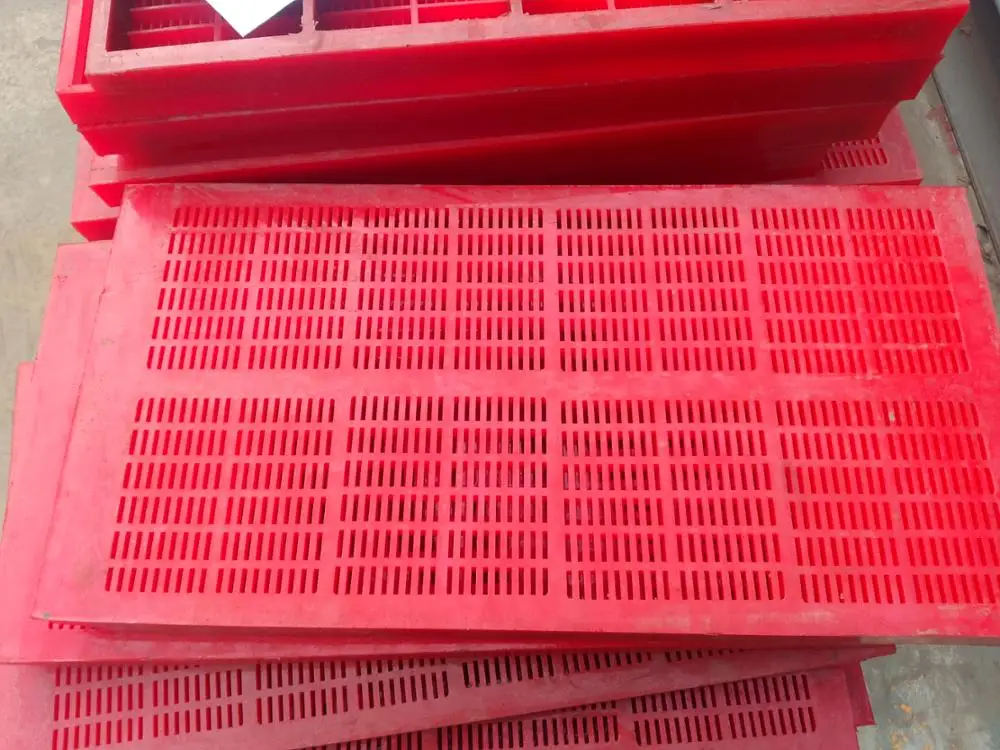

Polyurethane sieve plate display:

![F]CAUB8DX{X1O6C$W_R$QZ9.jpg](http://sc02.alicdn.com/kf/HTB1icsUhpooBKNjSZFPq6xa2XXaC/200069159/HTB1icsUhpooBKNjSZFPq6xa2XXaC.jpg)

It see well, do you have some customer testimonials

Which model you can choose?

Model | Material particle size(mm) | Discharging water content(%) |

Angle(º) | Amplitudes (mm) | Power (kw) | Dry material processing(t/h) | Shape dimension (mm) |

VD1036 |

0.15---1 |

15--30 |

0---5 | 2--4 | 2*5.5 | 20--35 | 3850*2185*2120 |

VD1236 | 2--4 | 2*5.5 | 35--50 | 3850*2390*2120 | |||

VD1536 | 2--4 | 2*7.5 | 40--85 | 3850*2700*2560 | |||

VD1838 | 4--6 | 2*7.5 | 50--100 | 4250*3100*2882 | |||

VD2138 | 4--6 | 2*7.5 | 70--130 | 4400*3360*2882 | |||

VD2545 | 6--8 | 2*11 | 90--150 | 4500*3700*2930 | |||

VD3060 | 6--8 | 2*11 | 120--200 | 6500*4365*3050 |

This dewatering vibrating sieve screen machine productivity

Certificate

The company has passed the ISO9001:2008, CE, BV certification.

Company Information

Gaofu company founded in 1982, 30 years of development history, gradually improve and integrated industrial chain;Main products include screening machinery, vibration equipment, crushed coal machinery, filtration equipment, dust removal equipment and other industries.With 56 national patents, is a design and production capacity of integrated machinery manufacturing company.

Our Team & Service

Basis service

1.Your sample material can be free analysis in our laboratory.

2.24 hours a week online & quick response within 12 hours.

3.Booking hotel and ticket for customers and Free transportation during visit our factory.

4. Production lead time and delivery time guaranteed.

After-sale services

After customers received the goods,if have any questions or quality problems, Our customer service Dept. will be always available.

Customer Visit

Our customers came from different countries every year.

1.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every macchine before delivery.

2.Guaranteed:

If products’quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about price?

Yes, we are factory and be able to give you the best price with good quality, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.

4.Service and Payment Terms?

A. We usually accept T/T, L/C;

B. T/T: 30% in advance as down payment, the balance before delivery;

C. We take pictures of finished products before delivery.

Tell me the following questions, Then I can send you accurate quotation soon, including additional discount!

Your email address and telephone will not be shared or published!

The proper selection of the vibrating screen depends on the material, mesh size, output required, method of input, abrasiveness of the material etc:

1. Material : _____

2. Moisture:_____%

3. Capacity:________kg/ hour

4. Screen layer:_______

5. Screen mesh size:______ mesh . ______ mesh. ______ mesh

6. Voltage:______V, Frequency:______HZ, 3 phase

7. SS304/316L stainless steel or Q235A carbon steel?

Contact a GAOFU professional-Angel Lu today.