Стальная пресс-форма производитель

- Категория: Пресс-формы >>>

- Поставщик: Foshan,YXH,Tube,Mill,&,Mould,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 2178.19 $* | 2287.43 $* |

| Aug-15-2025 | 2159.82 $* | 2267.98 $* |

| Jul-15-2025 | 1812.71 $* | 1903.7 $* |

| Jun-15-2025 | 2123.54 $* | 2229.61 $* |

| May-15-2025 | 1848.71 $* | 1940.1 $* |

| Apr-15-2025 | 2086.90 $* | 2190.13 $* |

| Mar-15-2025 | 2068.11 $* | 2171.12 $* |

| Feb-15-2025 | 2050.87 $* | 2153.45 $* |

| Jan-15-2025 | 2031.41 $* | 2133.98 $* |

Характеристики

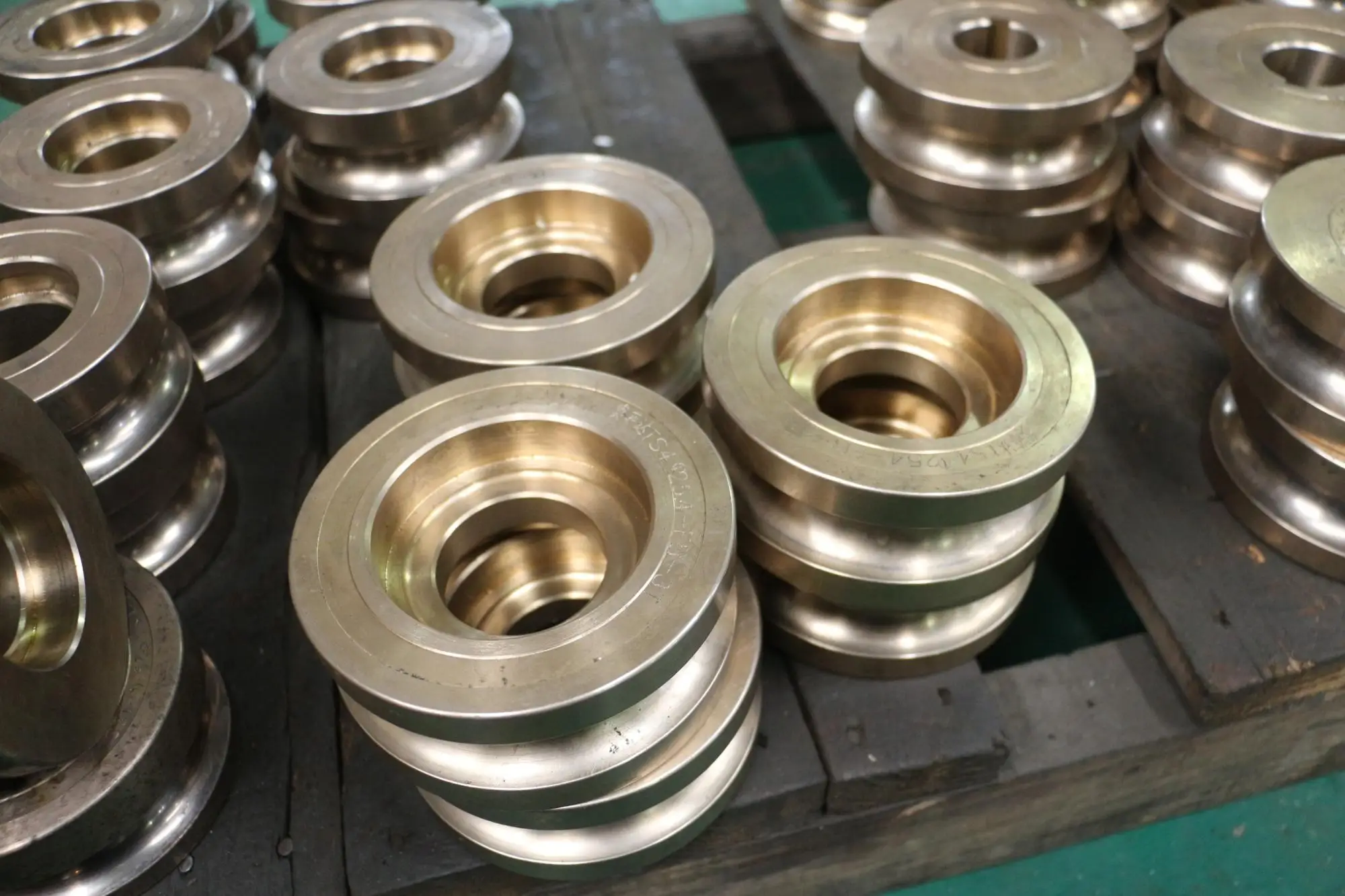

Steel Mould roll maker factoryMold production scope:

1.Round pipe: 4-335mm

2.Square pipe: 10 * 10-300 * 300 mm

3.Rectangular tube: 10 * 20-200 * 400mm

4.Production capacity monthly:7000 pieces

Click here to order and have your free to contact us

Your order are safer with Alibaba Trade Assurance

- On- Time shipment and per-shipment product quality safeguards

- Refund up the covered amost agree with us

Mold application:

According to the pipe shape,thickness and diameter you want to manufacture, install the mold on the pipe making machine, and you can start production.

Pipe Specs:

| Pipe Type | Specification(mm) | Tolerance Range | Hardness |

| Round Pipe | φ5~325 | Roundness+/-0.05 | HRC63~65 |

| Square Pipe | F10×10~F300×300 | Flatness+/-0.04 | HRC63~65 |

| Rectangle Pipe | F10×20~F120×60 | Flatness+/-0.04 | HRC63~65 |

Material:

| NO. | Material Science | Varieties |

| 1 | Cr12Mov | Dongbei special steel Cr12MOV/Daye special steel Cr12Mov |

| 2 | SKD11 | Daye Special steel SKD11/Taiwan SKD11/Japan SKD11 |

| 3 | D2 | Daye special steel D2/Taiwan D2 |

Roller Heat:

| NO. | Treatment method | Roller HRC |

| 1 | Vacum Heat Treatment | HRC61-63 |

| 2 | Vacum gas quenching and minus 200°C degrees, cooling, tempering, to improve the hardness. | HRC63-65 |

Product Strength:

Reduce strain and choose YXH moulds

We have professional designers and engineers to design drawings for each customer. Select high quality materials, after finishing and heat treatment, to produce high-quality mold. We also have a unique mold installation design, which can provide professional guidance in the easily damaged parts and select the most suitable mold. Reduce costs while minimizing strain.

Production Process:

Tube Roller Process:

Raw material - sawing material - rough processing - Drilling - fine finishing - roller polishing - Typing Code - semi-finished product inspection - heat treatment - grinding hole - horizontal die cutting KEYWAY - quality inspection - oil cleaning - packaging

Heat treatment way: There are four heat treatment way for your choose.

(1) Vacuum Heat Treatment :HRC 61-63

(2) Black treatment: HRC61-63

(3) Nit riding treatment: HRC61-63

(4) Vacuum Gas Quenching and Subzero Heat Treatment:HRC63-65

Warm reminding: Tube diameter≥133mm, HRC:58-61

Different heat treatment way , different price!

More information click to contact us

Our service:

Tube Roller Packing :

(1)Rust proof oil should be added to the export tube roller mould before removing the stains.

(2)Packing in wooden boxes, lined with paper and cloth , to avoid bruising ,then use shockproof membrane.

(3)The most outboard wooden packing , all the goods shipped by sea require fumigation wooden boxes.

After Service--Provide service 24 hours*7 days per week

1.Test the tube mill machine before shipment

2.Provide technical guidance relate to use the tube making machine

3.Provide the spare parts at cost price after warranty period

4.Collect the feedback for tube mill machine working

5.Provide long-term technical assistance

6.Offer the professional engineer to help you improve the output ,reduce the waste and decrease the cost.

- Our company is located in Foshan, and We have over 20 years of production experience.

- We have a professional design team and advanced U.S. processing equipment.

- Our products have been exported to more than 46 countries ,such as India, Vietnam,Bangladesh,Thailand,Pakistan,South Africa and so on.

1. What is the price for tube rollers?

It depend on your tube diameter ,thickness range and different raw materials ,different Heat treatment way ,tube roller prices is different.

2. How to make the final tube roller design?

On one hand , buyer can provide us the drawing of the whole rollers and we can provide OEM. On the other hand, As a professional tube roller manufacturer , we will make the tube roller according to your technical data of steel pipe making machine.

3. Factors affecting the price of welded pipe mold?

Tube Roller Raw Material: Cr12Mov, SKD11,D2

Tube mold design

Tube mould Heat treatment way

Tooling of tube mill Machining precision