Автоматическая машина для измельчения риса 20-30T/D 1 25

- Категория: Рисорушка >>>

- Поставщик: Guangzhou,Fengtai,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 8925.90 $* | 9371.36 $* |

| Aug-18-2025 | 8850.17 $* | 9293.45 $* |

| Jul-18-2025 | 7425.67 $* | 7796.40 $* |

| Jun-18-2025 | 8700.87 $* | 9135.11 $* |

| May-18-2025 | 7575.1 $* | 7954.8 $* |

| Apr-18-2025 | 8550.4 $* | 8978.16 $* |

| Mar-18-2025 | 8475.51 $* | 8899.93 $* |

| Feb-18-2025 | 8400.57 $* | 8820.99 $* |

| Jan-18-2025 | 8325.86 $* | 8741.0 $* |

Характеристики

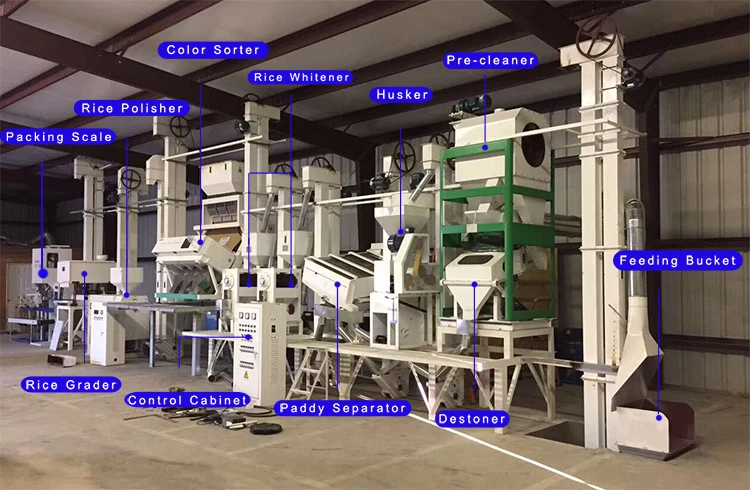

| 20-30 ton per day rice mill plant introduction (Automatic 20-30T/D rice mill machinery 1.25t/h complete combine rice mill machines best price rice mill plant): |

| 1. Available for both long-grain rice and short-grain rice(round rice), white rice and parboiled rice. |

| 2. It is practical and eco-friendly for whole line. |

| 3. High output rice rate and high precision quality rice, good for commercial rice business. |

| 4. Equipped with paddy precleaner & destoner for impurities and stones high removing rate. |

| 5. All spare parts are made by high quality materials, durable and reliable |

| 6. Compact and reasonable structure, labor saving, 1-2 person can operate the whole line. |

| 7. Both steel framed operation platform and concrete flated can be made for installation. |

| 8. Water polisher, color sorter and packing scale can be optional to suit customer's budget. |

Working Principle:

The auto rice mill is a kind of comprehensive equipment for rice processing. Rice goes into machine through vibrating screen and magnet unit, and then forward under rubber-roller for hulling. Winnowing and air blowing to husk. The machine will complete all the processing works from cleaning grain, rice husking in hulling to rice husking in succession. As to husk, chaff, blighted grain as well as polished rice, they are all pushed out of machine separately. This line is comprehensive expression for all the good qualities of rice-processing machines. In addition, it is arranged with a comprehensive view of situation and is designed rationally

Features:

1) High production performance which output up to 30T/D.

2) Low power required that around 44KW of basic system

3) Friendly operation and easy maintenance

4) Simple accessories,which directly supplied spare parts with factory prices

5) Cheap running cost brings more business activities.

| Model Name | Quantity | Capacity | Power |

| TZQY/QSX75 Combined Cleaner | 1 SET | 1.5-2.5T/H | 1.5KW |

| MLGT20B Husker | 1 SET | 1.8-2.5T/H | 4KW |

| MGCZ100*5 Paddy Separator | 1 SET | 1.3-2T/H | 1.1KW |

| MNMF15B Rice Whitener | 1 SET | 1.1-1.5T/H | 22KW |

| MJP63*3 Rice Grader | 1 SET | 1-1.5T/H | 0.75KW |

| Elevator | 5 SET | ||

| Optional Machine: | |||

| MPGW15 Water Polisher | 1 SET | 0.8-1.5T/H | 22KW |

| 128CCD Color Sorter | 1 SET | 1-3T/H | 2KW |

| DCS-50 Packing Scale | 1 SET | 5-50KG/BAG | |

| Elevator | 4 SET | ||

Pre-sale:

Product selection: Supply professional drawing and lists

Win-win cooperation: 1. Sign the contract 2. Establish mutual benefit, stratege.

In-sale:

Design evaluation: Design of process and equipment layout, electric power suggestion.

Installation: 1. Quality and quantity guaranteed 2. Completion of hand over

Acceptance: Acceptance test

Technical training: 1.On-site installation and products training

2. Operation skills training 3.Maintenance training 4. Centralized technical training.

After-sale:

Technical service: Long time technical service

Master device: Free supply during warranty period.

Accessories supplying: Supplying spare parts with cost.

Installation: oversea engineer can be arranged with cost.

Guangzhou Fengtai Machinery Co., Ltd. is an enterprise that specialized in grain and oil processing equipment manufacturing, engineering designing, installation and selling service.

1. With more than 20 years experiences.

2. Capacity to produce 2000 sets of varied rice milling.

3. Professional pre-sales & after-sales team to guarrantee the best satisfaction.

4. Skillfull engineering team for R&D persuiting the best performance of each machinery

Q1.What’s your advantage? Why we choose you?

A: 20 Years experience of design and manufacture grain machinery.We have the most professional techniques and team. Big advantage in price.

Q2.What’s the Payment?

A:T/T would be better with quick transfer and few bank fees. L/C could also be accept, but the procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4: Can you show how the machine works?

A: Certainly, we will send you the Operating video & instruction to you together with machines, to help you use the machines better.

Q5: How can I know your machine works well?

A: Before delivery, we will test and adjust the machine working condition for you, then you can use directly when you get it.