Leading SIECC Sheet Metal Surface for V CNC Keyway Planer 4000mm to

- Категория: Рубанок и долбежные станки >>>

- Поставщик: Nantong,Brillante,Industrial,Enterprise,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.25 $* | 0.33 $* |

| Aug-16-2025 | 0.64 $* | 0.59 $* |

| Jul-16-2025 | 0.23 $* | 0.63 $* |

| Jun-16-2025 | 0.73 $* | 0.47 $* |

| May-16-2025 | 0.44 $* | 0.76 $* |

| Apr-16-2025 | 0.36 $* | 0.36 $* |

| Mar-16-2025 | 0.91 $* | 0.89 $* |

| Feb-16-2025 | 0.78 $* | 0.1 $* |

| Jan-16-2025 | 0.2 $* | 0.25 $* |

Характеристики

SIECC B1250/4000 CNC SHEET METAL SLOTTING MACHINE/V-CUTTING MACHIINE

1, Main Parameter

No. | Project | Parameter | Unit | |

1 | Processing Capacity | Max. Length | 4000 | mm |

Max. Width | 1500 | mm | ||

Max. Grooving Thickness | 4 | mm | ||

Min. Grooving Thickness | 0.6 | mm | ||

2 | X shaft | Max. Travel | ≥4000 | mm |

Cutting Speed | 45000 | mm/min | ||

Returning Speed | 65000 | mm/min | ||

3 | Y shaft

| Max. Travel | ≥1500 | mm |

Movement Speed | 20000 | mm/min | ||

4 | Z shaft | Max. Travel | ≥100 | mm |

Movement Speed | 20000 | mm/min | ||

5 | X shaft | Motor Power | 5.5 | KW |

6 | Controlled shaft(X,Y1,Y2,Z) | 3+1 | Pc | |

7 | Machine Weight | 8000 | kg | |

8 | Dimension | Length | 6000 | mm |

Width | 2000 | |||

Height | 650 | |||

Note:

X shaft——left-right beam shaft

Y1 shaft——forward-backward knife rest shaft

Y2 shaft——forward-backward end pressure shaft

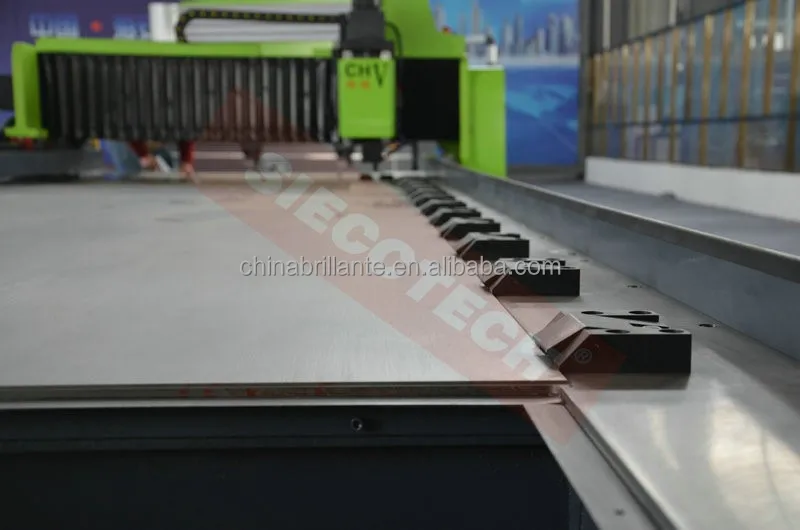

Z shaft——up-down knife rest shaft2. Structure characteristics

This machine is composed of machine base, - beam, turret, CNC system, air pressure feeding system, compressed air blowing system etc., for the gantry-travelling structure.

Frame, beams are made of box type structure, the finite element optimization design, all steel welded prior to milling machine, fully guarantee that no gaps between the board and the board, welding after tempering furnace to eliminate the residual stress, rigidity, good precision, long service life.

The forward-backward knife rest (Y1 shaft) movement, up-down knife rest (Z shaft) movement, forward-backward end pressure (Y2 shaft) movement are controlled by CNC system, AC servo motor, ball screw drive. It has the advantages of high control accuracy, positioning precision.

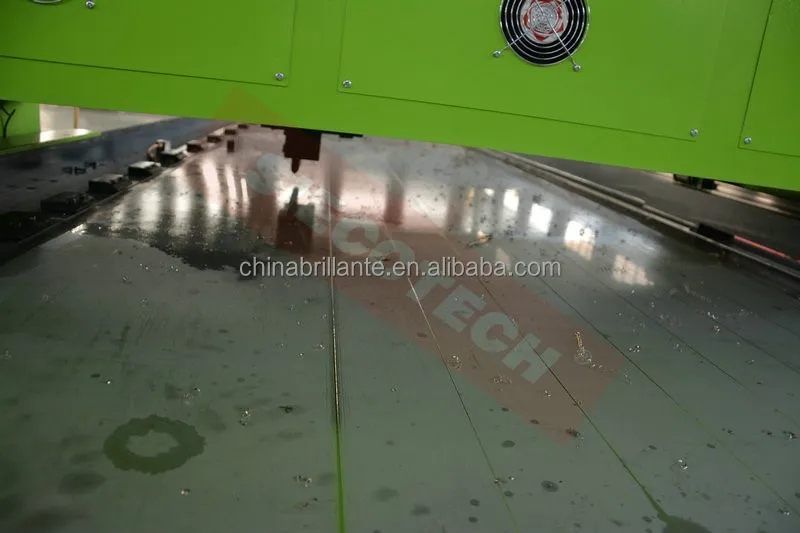

By air pressure feeding system, according to the different thickness of workpiece surface and adaptive feed side pressure, on board the pollution and effectively guarantee of environment and temperature, is one of the effective measures to ensure the machining accuracy and repeatability and accuracy.

Compressed air blowing material and cooling system, which can prevent the cutting scrap scratch the surface of the workpiece, but also through the tool cooling, improve the service life of cutting tools.

Increase in the pressure feed system of machine at the same side of the many to blowing system, greatly ensure the waste collection.

3. Performances

Has a stable, solid, features convenient use etc..

Multi parameter - control system has, large memory capacity, convenient operation.

Shafts of control for the 4 shaft, the 3 shaft AC servo motor system, the control precision is high.

With 4 knife cutting structure, which can greatly improve the work efficiency, and can improve the machining quality of the products.

Using motion system of ball screw, linear guide, improve the machine precision and durability.

4. Pneumatic system

Pneumatic system design, compact structure, strong sealing performance, long service life.

Imported pneumatic components, good sealing performance, low noise, fast response, good environment adaptability.

5. Electrical control system

Electrical components in line with international standards, safety and reliability, strong anti-interference ability.

Electric control adopts programmable controller, frequency conversion governor, non-contact operation, safety and reliability, long service life.

The main components of world famous brand products.

6. Before the pressure foot, lateral foot

The presser foot by quenching treatment, not easy to deformation.

7. Workbench

Adaptive work table, after process and special process, greatly improving the service life, such as improper operation table uneven situation, the machine has the function of self repair table.

8. The main parts list

How about your machine quality?We are worry about the quality.

SIECC is a mature brand in CHINA,through our many years research in technology,our design including structure and detailed sercurity and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry ,there are SIECC machines.And where there are our machines,there are good reputation and terminal user satisfaction.

Whether the machine price can be more discount

SIECC always provide high quality machine,as we know ,oversea market is more important and difficult than domestic market because of communication time costing after sales,So always,our machine has enough qaulity standard to make sure the machine can work more than the real warranty period.In this way ,we will save a lot and think in advance for the clients.

Actually SIECC also think about our price level,we are sure to provide quality=price and pice=quality ,the matched price and acceptable for the clients and durable for our machines.We welcome your negotiate with us and get a good satisfaction.

How about your manufactory in CHINA

SIECC located in HAIAN CITY,NANTONG,JIANGSU province who is the leading area in China and also in the worldwide as the center of the metal plate solution machines,We have worked about 10 years in this area and totally have about 150 staffs.Rich experience in this field with professional technical supporting and oriented service.

We welcome your visit to us any time.

Do you accept L/C payment term?

Yes,we accept 100% L/C at sign from almost all countries.