Оборудование для гранулирования органических удобрений

- Категория: >>>

- Поставщик: Harbin,Dadi,Biology,Organic,Fertilizer,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.46 $* | 0.54 $* |

| Aug-16-2025 | 0.86 $* | 0.49 $* |

| Jul-16-2025 | 0.1 $* | 0.11 $* |

| Jun-16-2025 | 0.48 $* | 0.54 $* |

| May-16-2025 | 0.63 $* | 0.1 $* |

| Apr-16-2025 | 0.47 $* | 0.40 $* |

| Mar-16-2025 | 0.4 $* | 0.49 $* |

| Feb-16-2025 | 0.9 $* | 0.51 $* |

| Jan-16-2025 | 0.27 $* | 0.69 $* |

Характеристики

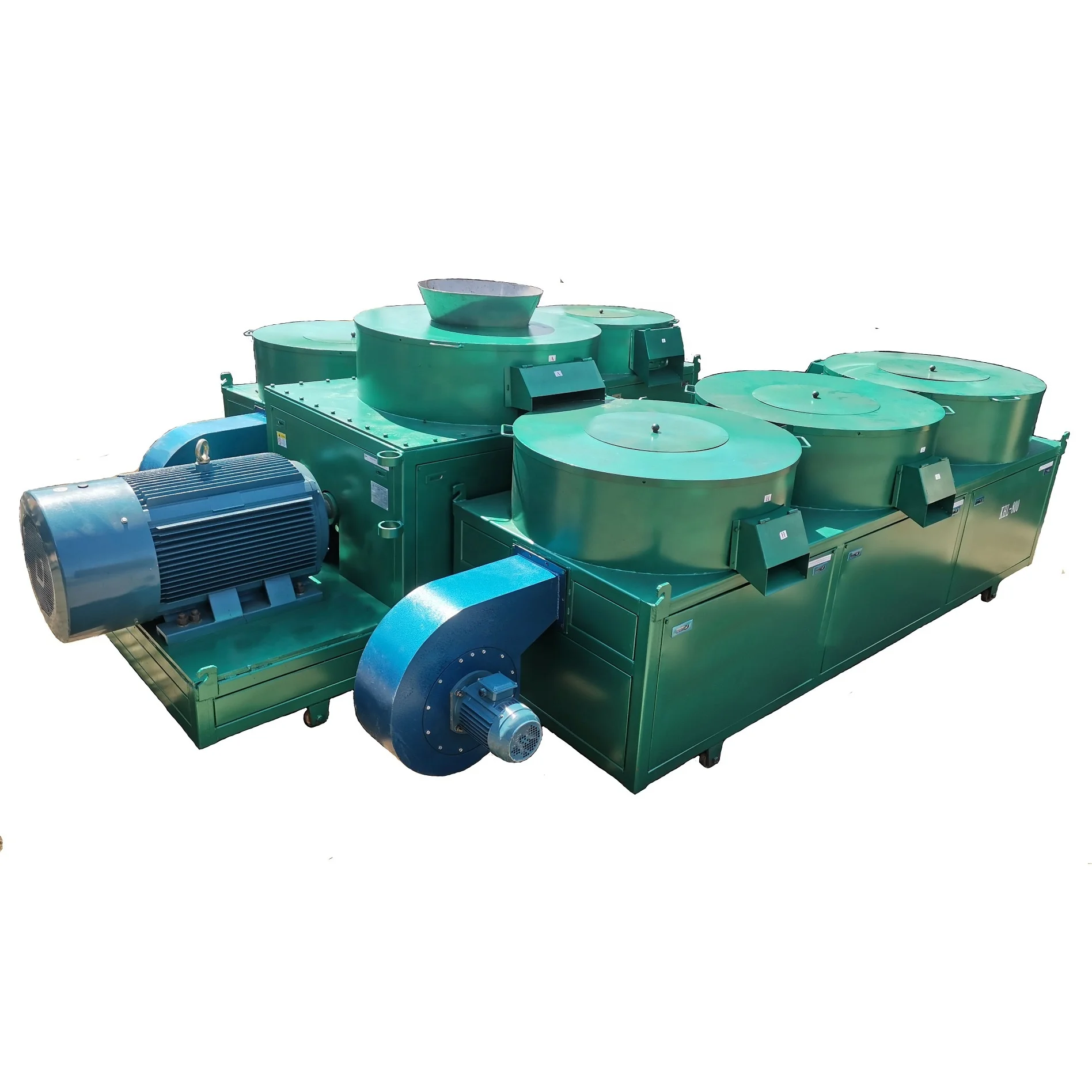

Vermicompost Organic Fertilizer Granulation Equipment![KHL-800 granulator]()

The granulation equipment are mainly used to make Organic waste into Round fertilizer granules.

Raw Materials

The granulation equipment can make the following raw materials into granules :

1.Agricultural waste: straw, dregs of beans, cotton dregs, rice bran,etc.

2.Animal manure: mixture of poultry litter (PL) and animal waste(AW),such as,Slaughterhouse Waste,Fish Market,Urine and dung of cow,Pigs,Sheep,deer,Chicken, Ducks, Geese,Goat,earthworm cast etc.

3.Industrial waste: wine lees, vinegar residue, manioc waste, sugar scum, furfural residue,Bean cakes, Vinasse slag, Biogas residue, Fruit residue, palm oil residue etc.

4.Residues of urban rubbish or sewage treatment plants.

5.Home scrap: food waste, bones, the roots and leaves of vegetables, etc.

6.Turfs, lignite, sludge, pond sludge,Sucrose slag,starch pulp.

7.Organic materials mix with mineral materials.

Advantages of granulation equipment:

1)One-time production of uniform spherical fertilizer granules with smooth surface and good hardness.

2)Adjust the hole diameters of ring die to achieve the optimal pelletizing results.

3)Granulation rate can reach 100%,all the raw material can be made into rounded fertilizer.

4) The rate of FINISHED product is more than 95%.

5) The organic content can be high to 100%, make pure organic granules.

6) No need to add binder.

How granulation equipment working?

The granulation equipment has two parts:

1. Pellets making part

The Pellets part with Ring die and rollers system :

The raw material goes into working chamber and fall on the ‘dump tray’, the raw materials throw into the ring die by centrifugal effect ; The ring die and rollers system turning drive by reduction gears & transmission which energy from motor . The pressure come from ring die and rollers system running ,cylinder form are forced extrusion from ring die hole ,which cutting into small pellets as required by cutting line .

2.Balling Parts:

The pellets fall onto the disk in the drum ,by high-speed rotating disk throw onto the wall of drum with circumferential movement , the granules in a circular motion at the same time also in radial rotation motion due to centrifugal effect . Mutual friction make the granules with edges and corners into balls gradually due to granules’ moving . At this moment , ball pellets gradually floating on the top , final granules overflow along with quantity of granules increased in the drum.

Technical Parameters of granular machine:

| Model | KHL-800 |

| Capacity:T/h | 6-8 |

| Input moisture content required:% | 30-35 |

| Moisture reduce after granulation:% | 3 |

| Input material particle size required:mm | 0.3-0.5 |

| Rate of finished products:% | >90 |

| Voltage:V | 380 |

| Granules size:mm | 3.5-5.5 |

| Power:KW | 162 |

| Total weight:Kg | 10000 |

| Size:m | 6.5*3.9*1.9 |

| LCL | FCL | |

| Way | Wooden cases with steel frame | Container |

| Packaging Details | The normal package is wooden box (Size:L*W*H).If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pefilm for packing or pack it according to customers special request. | Loaded into container |

1. Design the production line for you.

2. Design factory layout according to your requests and factory size.

3. Sample testing support.

4. Offering comprehensive technical and business consultation services.

5. Fast & Safe Delivery.

6. Training how to install the machine, how to use the machine and maintain.

7. Engineers available to service machinery overseas.

You can enjoy drawing design, equipment building, installation and running etc.full one-stop services from us.

Main products:

Organic fertilizer granulator machine /Organic fertilizer production line

Animal feed pellet machine

Biomass fuel pellet machine

Rotary drum dryer

Rotary drum cooler

Crusher

Grading screen machine

Certification

1. Are you manufacturer or trading company?

We are manufacturer.

2.What is the payment terms?

We usually accept T/T.

T/T: 30% in advance as down payment, the balance before delivery.

We take pictures of finished products before delivery.

3.How about price?

We are factory and be able to give you the lowest price than market one.

4. Do you accept customized?

Yes , we have different customer make their own OEM product.So we also can make product as per your requirement.

5. Can I get some samples before place order and how long for a sample?

No. Because our product is big and high price.But we can test your material and send the video to you.

6. How is your shipping?

Shipping by sea.

Worldwide shipping service available

Please contact before order as shipping cost varies time to time.

7. How long is your guarantee?

12 months warranty but except quick wearing parts.