Скребок для биогаза Camda/скребок метанового газа/скребок

- Категория: Биогаз >>>

- Поставщик: Camda,New,Energy,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.61 $* | 0.56 $* |

| Aug-19-2025 | 0.90 $* | 0.94 $* |

| Jul-19-2025 | 0.80 $* | 0.25 $* |

| Jun-19-2025 | 0.20 $* | 0.27 $* |

| May-19-2025 | 0.92 $* | 0.30 $* |

| Apr-19-2025 | 0.50 $* | 0.25 $* |

| Mar-19-2025 | 0.47 $* | 0.37 $* |

| Feb-19-2025 | 0.63 $* | 0.48 $* |

| Jan-19-2025 | 0.12 $* | 0.20 $* |

Характеристики

Camda biogas scrubber/methane gas scrubber/sulphure remover

KDCL-100 series Biogas Purifying System

1. Main Specifications

Model KDCL-100-WQ

The suitable genset power 50KW-120KW

Dimension 2000×2000×2240 (mm)

Weight 2800kg

Gas flow 80~120Nm3/hr

Working pressure 4~40KPa

Desulfurizer amount 2×300kg

The changing time of desulfurizer 1500 hours

Parts per million after purifying 200ppm

The designed lifetime 15years

2.The main function of this system

1. Desulfurization

2. De-dust

3. De-water

4. Increase pressure

5. Steady pressure

6. Change desulfurizer without stopping genset

3. Technical Characteristic

Technical Characteristic: stable desulfuration efficiency which reaches beyond 99.3%. Combined with biogas features, the technology is improved and evoluted from mature gas desulfuration process which once is used in chemical industry and Fertilizer industry. Now the biogas purification and desulfuration system, adopting this technology, is equiped with Camda gas genset.

Desulfurization:

Wet scrubber is recommended for desulfurization. After gas goes through wet-process desulfuration, most of hydrogen sulfide is removed. In this technology, desulfurization solution is recycled. So no polluted water is discharged. The by products, sulphur, from this process can be sold to sulfuric acid factory. All the equipment and chemical agent are non-toxic, harmless and of easy operation without any potential safety hazard. Comparing with using sodium hydroxide and dry process desulfuration, Wet scrubber has the advantages of high efficiency and low running cost. This technology has been upgraded on the basis of tanning extracts desulfuration, which has reached the international advanced level.

Dehydration:

After gas by wet method desulfurization after and absorbing hydrogen sulfide, will bring less mist shape desulfurization liquid,the moisture content is too high, will be condensed in pipeline and accumulation in the lower position of pipeline that make gas circulation impeded,also winter easy cause frozen blocking phenomenon.Therefore need dewatering.Dewatering under atmospheric, first after centrifugal dewatering,and then after packing dewatering that can dewatering the liquid water of gas.

No. | Material name | Spec/Type | Material | Qty |

1 | Dry-type desulfurizer | KDTL-400-G Φ600×2080×δ3.0 | SS304 | 2/1set |

2 | Despumation buffer tank | KDFC-400-G Φ500×1540×δ3.0 | Q235A | 1set |

3 | Biogas booster pump | 60-150m3/h,1.5kW NSR65-65A | Assembly | 1set |

4 | Variable frequency electrical control box | AB 22BD6PON104 1.5kW | Assembly | 1set |

5 |

Debugging fee of transportation and installation

| PN10/DN65 | PVC / δ4.5 | 1Pcs |

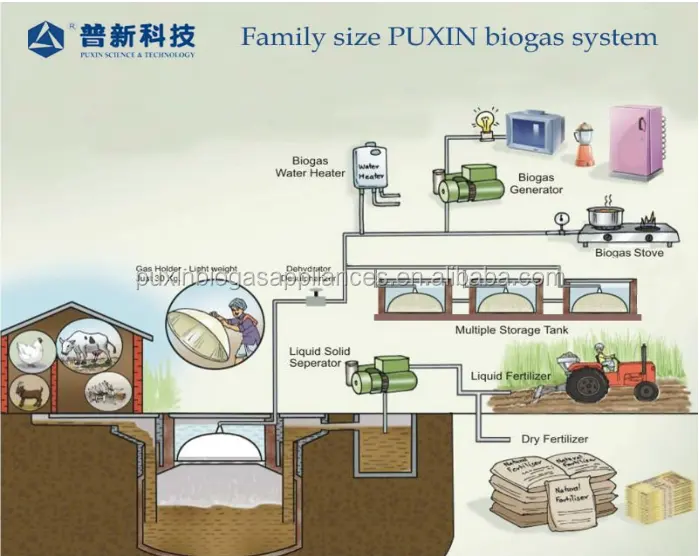

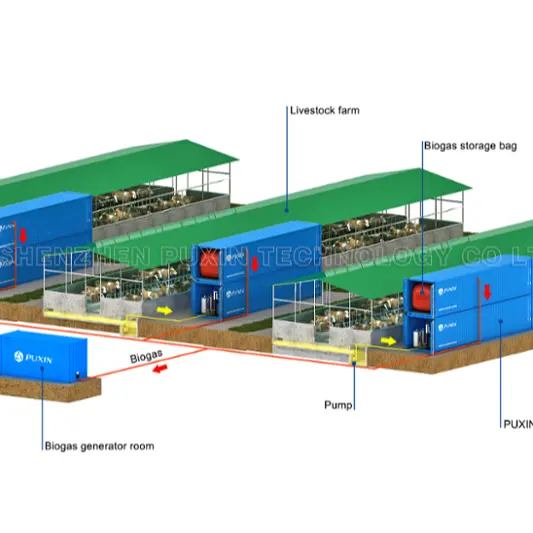

Photos: