Высококачественная Порошковая угльная горелка для цементной лаймовой вращающейся

- Категория: Energy Saving Equipment >>>

- Поставщик: Henan,Zhengzhou,Mining,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.5 $* | 0.40 $* |

| Aug-15-2025 | 0.66 $* | 0.7 $* |

| Jul-15-2025 | 0.56 $* | 0.17 $* |

| Jun-15-2025 | 0.95 $* | 0.73 $* |

| May-15-2025 | 0.82 $* | 0.64 $* |

| Apr-15-2025 | 0.95 $* | 0.74 $* |

| Mar-15-2025 | 0.71 $* | 0.36 $* |

| Feb-15-2025 | 0.99 $* | 0.61 $* |

| Jan-15-2025 | 0.76 $* | 0.99 $* |

Характеристики

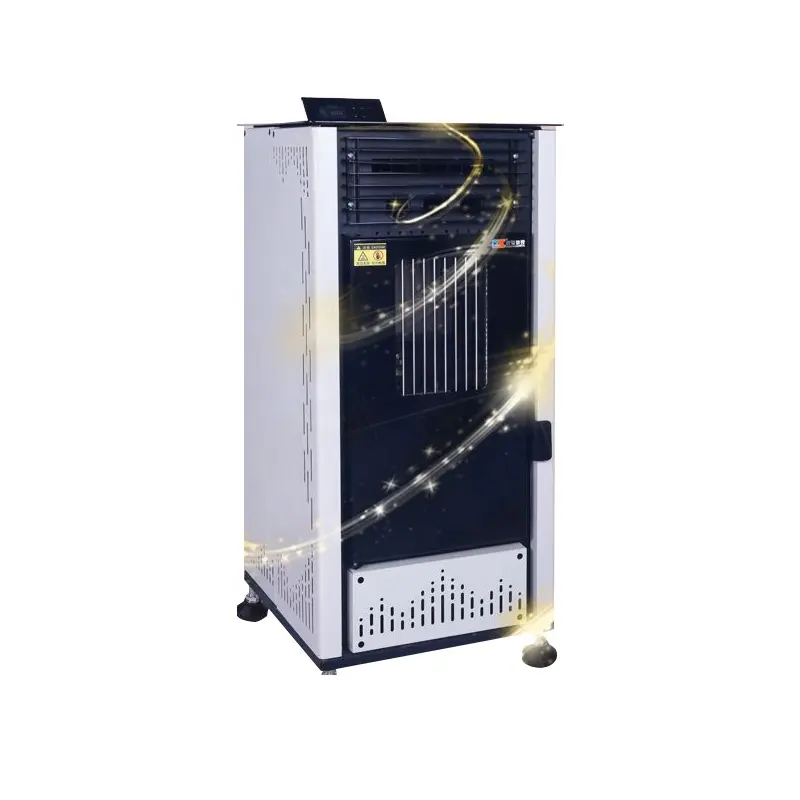

High Quality Pulverized Coal Burner for Cement Lime Rotary Kiln

Pulverized Coal Burner is fit for coal burning system of middle and small rotary kiln, it has such below features: sufficient burning, flame powerful, strong, not hurting kiln coating, repairable , low expense of after-sales service. And the main parts are made of high temperature resistance ceramic element, it is more stable and reliable when working, the system investment is small.

Pulverized coal burner technical advantages:

1. Pulverized coal burner and flue gas emissions to Ringelmann 0-1 degree level;

2. Pulverized coal burner with a fixed carbon content of ash in about 0.1 percent, the basic free toner;

3. New pulverized coal burner of the energy-saving rate of 15-30%;

4. Burner gas content in the flue dust without any equipment to use under the circumstances the flue, as long as the oxy-acetylene burning fully, you can reach the national standard.

Main characteristics of pulverized coal burner:

1.Pulverized coal burner in the high temperature region to stay a long time, thus the combustion efficiency, flue directly discharged without smoke, white smoke was steam-shaped;

2.This type of coal burner heating time when the temperature rise, thermal efficiency, and low coal quality, coal applies to a wide range of high economic benefits;

3.MRQ easily pulverized coal burner ignition, warming quickly, greatly improve work efficiency;

4. The burner air supply volume, the importation of coal-fired capacity will be changed on-demand, and can be adjusted in a wide range of temperature and flame length, to meet actual needs;

5.Pulverized coal burner internal temperature field uniformity, the furnace is heated within the coverage of body heat, and slag in a non-stick surface, the product of good quality.

Parameters of pulverized coal burner:

We have advanced production technology and management. Our professional engeneers and after-sales groups production technology can offer convienient service for our customers .

Pro-sales

(1)To guide to choose more proper product.

(2)To design the best scheme for free.

(3)To design and make the products according to the special demands.

On-sales

(1)To arrange strict examinations before the product is delivered.

(2)To deliver products according to the contract.

After-sales

(1)To send an engineer to guide to install and try-run the machines on the spot.

(2)To debug and try-on.

(3)If any problem occurred in the products,we would give the right solution as soon as possible.

Henan Zhengzhou Mining Machinery Co., Ltd was established in 1956, It was a designated factory by Ministry of Machinery Industry and Henan Mechanical electronic bureau to produce cement, washing and separation equipments. Over half a century, It has been a comprehensive enterprise combined with research, design, develop, manufacture, sales, installation, commissioning, training service from a single machinery producer. The company covers an area of 60000m², the building area is 35000 m², with fixed capital 100 million RMB.

Achievements:

2004--2006 Successfully design and manufacture new type energy saving dolomite calcination equipments with the way "vertical kiln +rotary kiln +vertical kiln", which realize high efficiency, energy saving, environment, safe, higher automation in calcination process.

2007--2008 Develop burning device lower heat value, The fuel for rotary kiln can be the lower heat value gas with 1200Kcal/Nm3,it does not need add coal powder.

2009--2010 Develop star wheel ferrosilicon crusher, high efficiency, crushed particle in cube, well-formed and uniform, 85% particles in 3-6mm,low content in flaky and powdery, good for grinding and mixture.

2011-- now Develop and trial produce the high efficiency crawler Loader, propose the new idea that combined the " slag and gas separate rapidly" and "gas purification" together. The theoretical samples machine was finished cold and hot condition test and move to manufacture phase.