Компас флоппи бетон штамп коврик цемент

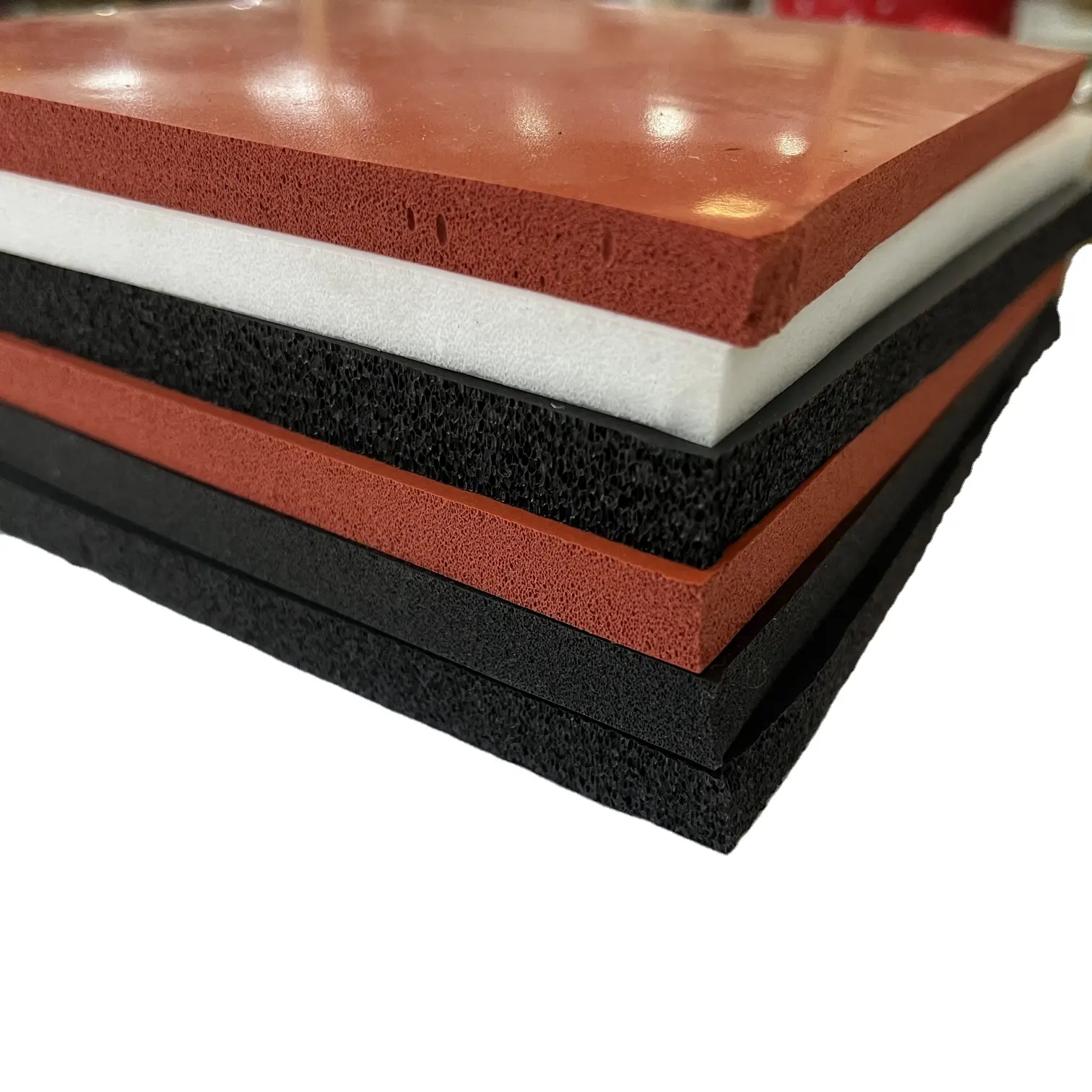

- Категория: Silicone Rubber >>>

- Поставщик: Zhengzhou,Ystone,Construction,Materials,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.92 $* | 0.81 $* |

| Aug-20-2025 | 0.80 $* | 0.5 $* |

| Jul-20-2025 | 0.2 $* | 0.85 $* |

| Jun-20-2025 | 0.36 $* | 0.11 $* |

| May-20-2025 | 0.39 $* | 0.32 $* |

| Apr-20-2025 | 0.85 $* | 0.70 $* |

| Mar-20-2025 | 0.6 $* | 0.75 $* |

| Feb-20-2025 | 0.51 $* | 0.87 $* |

| Jan-20-2025 | 0.17 $* | 0.9 $* |

Характеристики

Why stamped concrete?

Stamped decorative concrete is an attractive and economical alternative to natural pavers or just plain poured concrete. A stamped concrete patio can give you the look and texture of a stone patio for a lot less than the real thing, sometimes less than half the cost of the natural material alternatives such as slate.

And actually, slate and stone is not where it ends. Stamped concrete can mimic brick, cobblestones, weathered wood and even a seashell laden beach. Add in some fun borders, footprints or even fallen leaves and you are creating surfaces you simply cannot get with natural materials. Another major advantage to a stamped concrete patio is generally low maintenance. The pavers or stones won't settle over time, allow sprouting plant growth in between and creating uneven surfaces.

The Advantages of Polyurethane Concrete stamp mat:

Step by step to make Concrete Stamping:

Step 1,

Step 1: Making the wet cement floor to even, no water hole on the surface.

Step 2,

Step 2: Casting color hardener on the cement floor, normally 3-4kg on 1 square meter.

Step 3,

Step 3: when the color hardener is humid, making the floor smooth with bull float.

Step 4,

Step 4: Casting release agent on the floor, normally 0.15kg on 1 square meter.

Step 5,

Step 5: Stamping the floor with concrete stamp mat and Plate Temper.

Step 6,

Hold 3days for curing, then spray sealer on the floor, 0.2kg on 1 square mater.

Quality:

Main Features:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to make stamping.

* Guarantee for the products quality with 2 years.

* Good price for new designs.

Zhengzhou Ystone Mould Construction CO., LTD

is professional on manufacturing plastic mould for concrete constructions, which covers a great range, including concrete stamp mat, plastic paver mould, curbstone mould, Planter flower pot mould, column pillar mould, Baluster mould, Silicone artificial stone mould, the mould is perfect for road pavement, house and Garden decoration, stamp landscaping and villa culture stone decoration.

In the Past 5 years, Our company are expanding Overseas Market, and our plastic moulds get remarkable market in USA, European Countries, Chile, Malaysia, Kenya, Uganda, Burundi, Gambia, Tanzania, Mali, Nigeria and Ghana, Jordan, Lebanon and UAE,

We are Glad to hear our Customers to make their home and garden fashion and personality with our Plastic Mould. Confidently, We are warmly looking forward to your visit and cooperation.