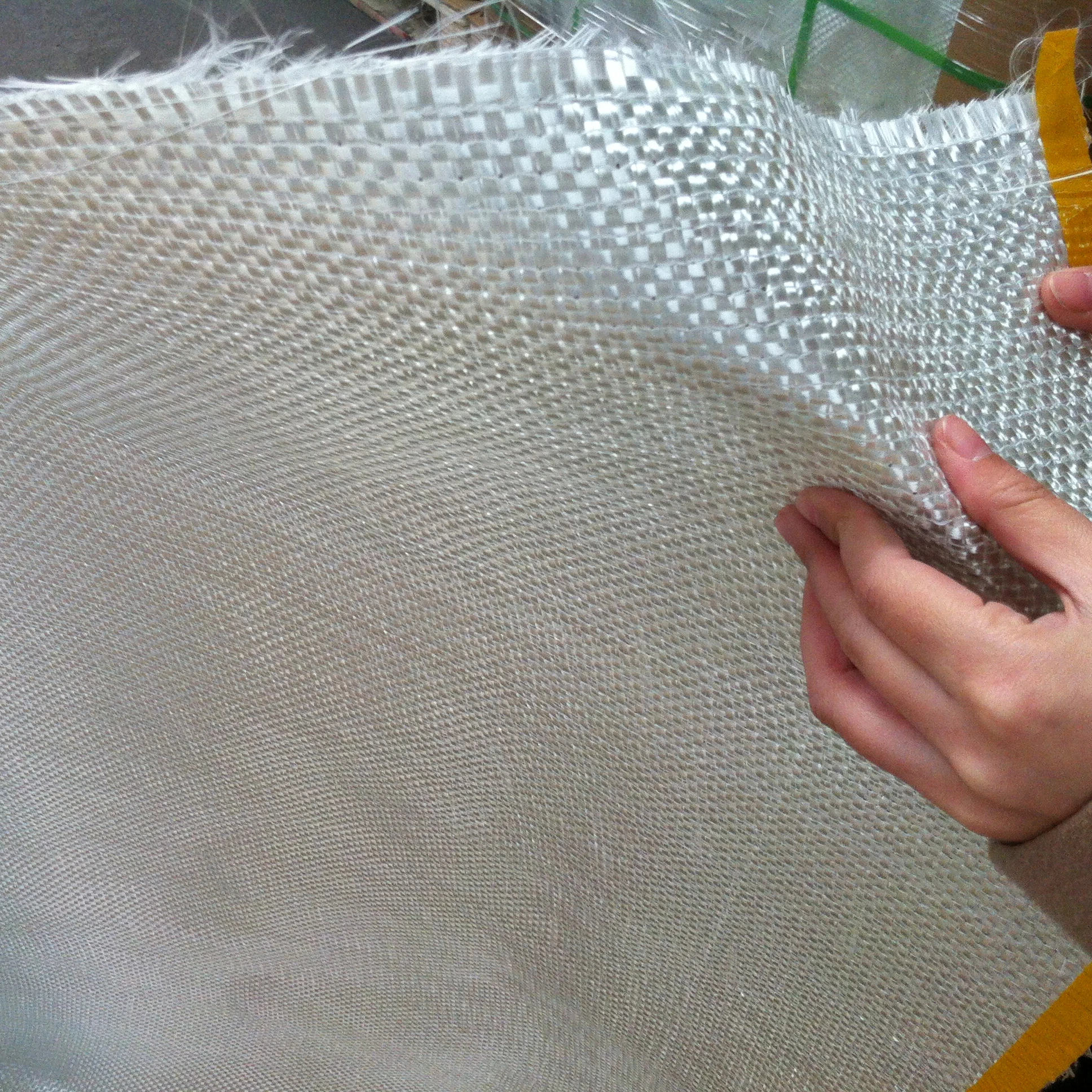

Комбинированный плетеный коврик из стекловолокна 900 г сшитый рубленый ниток ECM600/300 1250 мм для лодки ручная

- Категория: Стекловолокнистое полотно >>>

- Поставщик: Qingdao,Rockpro,Composites,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.50 $* | 0.8 $* |

| Aug-18-2025 | 0.40 $* | 0.31 $* |

| Jul-18-2025 | 0.37 $* | 0.98 $* |

| Jun-18-2025 | 0.5 $* | 0.14 $* |

| May-18-2025 | 0.22 $* | 0.18 $* |

| Apr-18-2025 | 0.25 $* | 0.56 $* |

| Mar-18-2025 | 0.56 $* | 0.86 $* |

| Feb-18-2025 | 0.39 $* | 0.86 $* |

| Jan-18-2025 | 0.21 $* | 0.96 $* |

Характеристики

Stitched Fiberglass Combo Mat

Woven Roving + Chopped Strand

It is made of woven roving and chopped fiberglass strand complex of, then stitched together with polyester yarn. It is compatible with Polyester, Vinyl and Epoxy resin and widely used in boat building, Auto parts, refrigerated tools and structural sections industry etc, suitable for hand lay up, RTM, pultrusion, vacuum processes.

Roll width

Standard width in 1250mm, 1270mm, and other sizes depends on customer’s real needs, available in 200mm to 2600mm.

General Data

Code | Weight (g/m2) | Woven roving (g/m2) | Chopped strand (g/m2) | Moisture Content | Wet speed (≤S) | Layer |

EWRM200*200 | 400 | 200 | 200 | ≤0.2 | 60 | 2 |

EWRM300*300 | 600 | 300 | 300 | ≤0.2 | 60 | 2 |

EWRM400*300 | 700 | 400 | 300 | ≤0.2 | 60 | 2 |

EWRM500*300 | 800 | 500 | 300 | ≤0.2 | 60 | 2 |

EWRM500*450 | 950 | 500 | 450 | ≤0.2 | 60 | 2 |

EWRM600*300 | 900 | 600 | 300 | ≤0.2 | 60 | 2 |

EWRM600*450 | 1050 | 600 | 450 | ≤0.2 | 60 | 2 |

EWRM800*300 | 1100 | 800 | 300 | ≤0.2 | 60 | 2 |

EWRM800*450 | 1250 | 800 | 450 | ≤0.2 | 60 | 2 |

Storage

The product should be stored in a cool, water-proof area. It is recommended that the room temperature and humidity be always maintained at 15℃ to 35℃ and 35% to 65% respectively. Please keep the product in its original packaging before being used, avoiding moisture absorption.

FIBERGLASS COMPOSITES FABRIC:

Glass fiber composite felt is made of glass fiber-free roving yarn arranged in one-way parallel, the outermost layer is cut into glass fiber yarn or short-cut felt of a certain length, and is sewn with organic fiber.

Mainly used for FRP pullout RTM forming, hand lay up molding and other processes, the end products are mainly FRP hull, car shell, plate, profile and so on.

Fiber structure can be designed to provide high strength in a certain direction;

The fiber is not easy to produce displacement and deformation, easy to operate;

Fabric without any binder, easy to soak;

The compounding of the structure can reduce the layering and effectively improve the production efficiency.