Высококачественный гранитный аппарат для боковых

- Категория: Silos >>>

- Поставщик: Zhangjiagang,Gihua,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 535500.1 $* | 562275.12 $* |

| Aug-17-2025 | 531000.30 $* | 557550.93 $* |

| Jul-17-2025 | 445500.14 $* | 467775.10 $* |

| Jun-17-2025 | 522000.33 $* | 548100.47 $* |

| May-17-2025 | 454500.32 $* | 477225.64 $* |

| Apr-17-2025 | 513000.92 $* | 538650.91 $* |

| Mar-17-2025 | 508500.78 $* | 533925.87 $* |

| Feb-17-2025 | 504000.54 $* | 529200.3 $* |

| Jan-17-2025 | 499500.66 $* | 524475.8 $* |

Характеристики

Product Description

Maximum production speed: not less than 18 meters per minute (for non-perforated profiles, excluding cutting);

Bending precision: the maximum profile deviations (dimensions and shape) shall not exceed the tolerances specified in EN 10162 (or equivalent tolerances);

Bending quality: ability to bend the profiles of the specified configuration at the specified maximum steel thickness; cracking of the steel or metal coating is not permitted for all required steel grades, when observing the products under magnification ten times.

Main Features

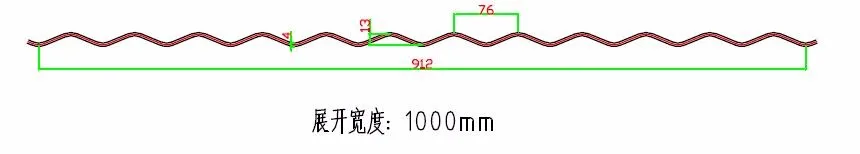

1) Material of the profile: 195-235Mpa GI or carbon steel

2) Thickness range: 3-4mm

3) Main motor power:60kw, AC motor, motor inside of main machine (Brand: Guomao of China) (according the final design)

4) Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

5) Roll station: about 20 stations (according the final design)

6) Roller material:Gcr15 bearing material chrome plated surface with hardness 58-62 degree ,CNC,

7) Shaft diameter: 150mm material: SAE1045 with quenching and tempering

8) Machine roll forming speed:18m/min

9) Transmission: by gear box 200*500(outside is cast iron, surface needed polish and paint. Inside is 60# forge and press metal)

10) Roll former has leveling bolts in the base for adjust the leveling

11) Machine base frame adopt H beam welding steel

12) In the main roll forming machine have 2 buttons for urgency stop if happen any malfunction.

13) Machine adopt new station to make machine more strong

14) To avoid accidents,all of drive part adopt protect cover

15) Color of machine: Blue and yellow (or base on customer request)

Detailed Images

10T hydraulic decoiler:

Steel coil width: from 1250 mm to 1500 mm;

Internal diameter of coil: variable, from 470 mm to 620 mm

Maximal out diameter:1600mm

Maximum coil weight: 10000 Kg;

Oil cylinder dia:120mm

Working speed: 0-15m/min adjustable

Main motor power: 7.5KW AC motor

Hydraulic power: 5.5kw

Speed controlled by frequency converter brand: Yaskawa

De-coiler should be with Loop control and hold down, and with baffle for forbid coil fall down

The decoiler has 4 segments

Forming section

Material of the profile: 195-235Mpa GI or carbon steel

Thickness range: 3.0-4.0mm

Maximum production speed: not less than 18 meters per minute (for non-perforated profiles, excluding cutting)

Main motor power:60kw, AC motor, motor inside of main machine (Brand: Guomao of China)

Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

Roll station:20 stations

Roller material:Gcr15 bearing material chrome plated surface with hardness 58-62 degree ,CNC,

Shaft diameter: 150mm material: SAE1045 with quenching and tempering

Transmission: by gear box 200*500(outside is cast iron, surface needed polish and paint. Inside is 60# forge and press metal)

Punching:

The punches and dollies will be CR-12, hardness HRC 58-62 and chrome coating both punches and dolies should be easily replaceable without requiring disassembly of complete units.

The whole punching operation should be automated and controlled by a program installed in the PC which is located in the operator's console.

Hydraulic power: 5.5kw

Working pressure: 12-16Mpa

Cutting :

Machine adopt hydraulic cutting

Cutting after forming: Cut the sheet after roll forming to required length

Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

Material of blade: CR12with heat treatment

Length measuring: Automatic length measuring

Tolerance of length: 4700mm+/- 2mm

Auto stacker and transmission table:

Air cylinder swing arm size: 40mmx80mm

Transmission power:4kw AC motor

Stacker length in 12m, transmission table length in 25m

Drive of transmission by 1.0inch double line chain

Transmission roller: ASTM1045 with chrome, diameter of roller is in 80mm

Carrying capacity: maximal 5000Kgs

Length of capacity: 500-12000mm

The maximal stacker height: 300mm

Hydraulic station:

Hydraulic power: 11kW

Working pressure: 20-25Mpa adjustable

Solenoid valve: 3 group

Hydraulic oil: 46# hydraulic oil

Color: Blue (or base on customer request)

Control carbinet:

2)Automatic stopping of the equipment after completion of the cutting programme.

5)PLC brand: Panasonic

6)Frequency converter brand: Yaskawa, quantity: 1

7)Touch screen: Taiwan Weinview

Package&Delivery

FAQ

If any needs or questions, feel free to contact me please.

We would like to design the machine for you

Mob/WhatsApp: 008618551231440

WeChat: 243554222

Certifications