Машина для обработки жидких

- Категория: Tobacco Processing Machinery >>>

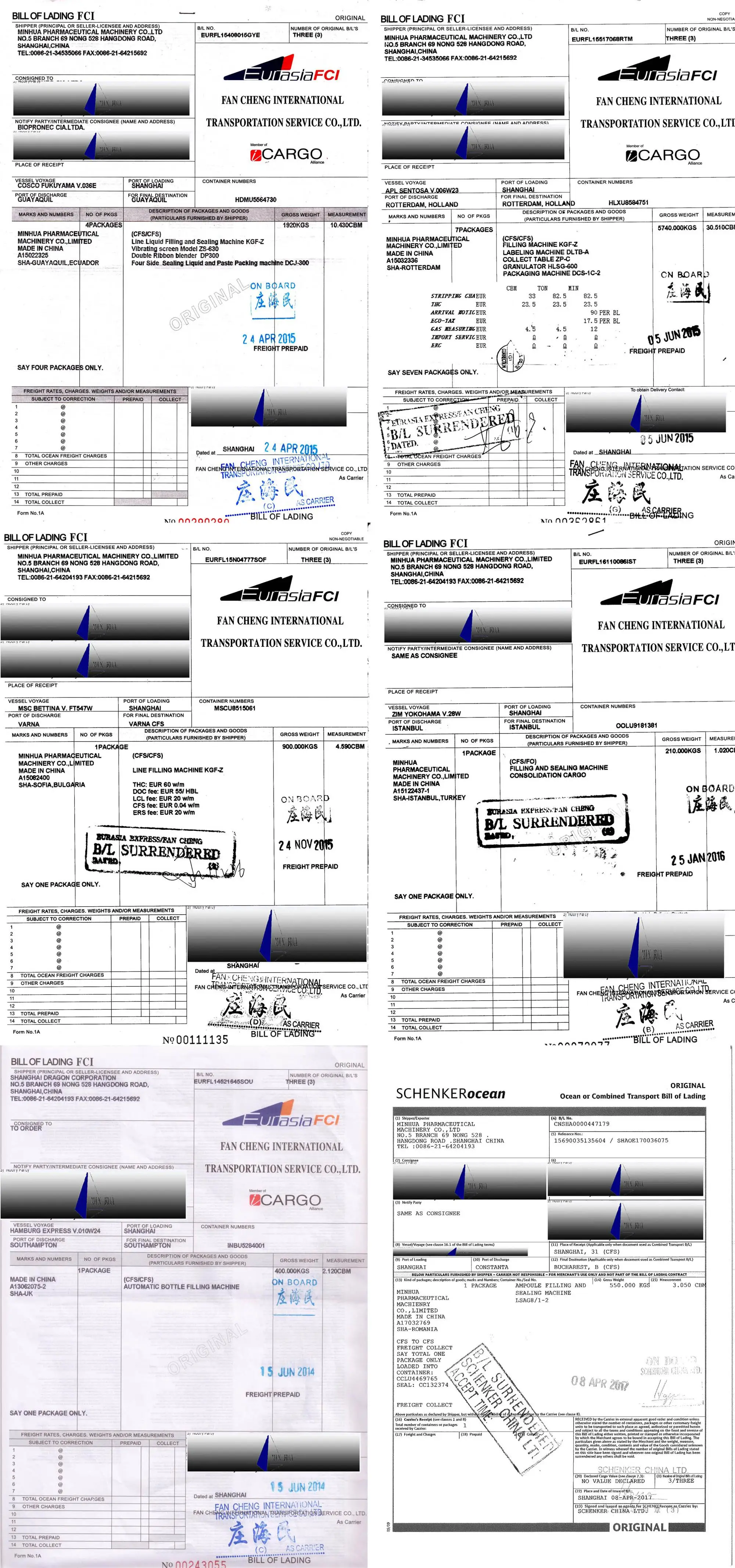

- Поставщик: Minhua,Pharmaceutical,Machinery,Co.,Limited

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.58 $* | 0.3 $* |

| Aug-16-2025 | 0.12 $* | 0.35 $* |

| Jul-16-2025 | 0.74 $* | 0.58 $* |

| Jun-16-2025 | 0.67 $* | 0.94 $* |

| May-16-2025 | 0.94 $* | 0.70 $* |

| Apr-16-2025 | 0.57 $* | 0.35 $* |

| Mar-16-2025 | 0.9 $* | 0.34 $* |

| Feb-16-2025 | 0.52 $* | 0.53 $* |

| Jan-16-2025 | 0.37 $* | 0.83 $* |

Характеристики

Product Description

bottle processing machine/Gravity Filling Machine

1. The machine is a auto-liquid filling devise which is composed of PLC, human-computer interface, optoelectronic sensor and air-powered. The machine adopts time control theory, switch time of the solenoid valve control the filling dose precisely. The machine is unique in simple operating, stable performance, accuracy measuring, no dripping or leaking and convenient in changing model. It is widely used in pharmaceuticals, food industry, Cosmetics, agricultural chemical, chemical industry and etc.

2. The machine adopt linear filling. The bottle conveyed through conveyer belt. When the bottle arrives at the blocking bar, the bottleneck is rightly below the filling pipe. After the optoelectronic sensor detecting the last bottle and delay a while, the filling cylinder opens and the liquid filled into bottles. Blocking bar at the outlet draws back after bottles filled. The bottles filled deliver by the conveyer belt. the filling done. The blocking bar at the inlet transport the next set of bottles.

3. (1)The filling machine stops automatically and alarm when lack empty bottle or no bottle enters and optoelectronic sensor at the inlet doesn’t detect signal.

(2)When the following line blocked, the filled bottle can’t deliver, the optoelectronic sensor at the outlet detects the signal and stop filling automatically.

Line liquid filling machine RG-8

filling range | 50~1000ml |

filling speed | 20~100 bottles/min |

filling precision | ≤±1% |

voltage | 220V |

mains frequency | 50Hz |

power | 2.5kw |

Working barometric pressure | 0.4~0.6MPa |

Air consumption | 0.4 /min |

weight | 470kg |

size | 2060×780×2100mm |

Different machine models:

Remark: Machine will be designed according to customer's detail requirements. Please contact with us for choose.

Product Pictures

Cleaner

Details

Product Samples

Packaging & Shipping

Our Company:

Shanghai Zixiong Pharmaceutical Machinery Co., ltd is a professional manufacturer and supplier of pharmaceutical and chemical machinery and equipment in China. We are located in Shanghai.

We have a disciplined factory and fairly professional technical engineers. We will provide personalized customized service for you. We have designed and developed many types of machinery and equipments, including tablet press, soft and hard blister packing machine, capsule filling machine,

clean-room project, soft-gel production line, glass-lined reactor, centrifuge, granulator, mixer, dryers, pulverizer, cartoner and rollers, etc.

Our products are of good quality and reputation. All customers have been quite satisfied with our products. We have established long-term business relations with many customers. Our products are exported to many countries & areas, such as the USA, Australia, Canada, the UK, Spain, Hungary,Russia,Germany, Sweden, Korea, India, Indonesia, Pakistan, Thailand, Vietnam, , Japan, Denmark, Romania, Bulgaria, , South Africa, Nigeria, Argentina and Chile. Besides machinery and equipment, we also supply production lines and turn key projects.

In ZIXIONG you can get your desired goods with the best prices and good quality. Welcome your enquiries from all over the world.

Our Services

Pre-sales service:

1.We provide presales service in various forms, making investment budge, manufacturing, planning, so that customers can make a reasonable plan with less cost.

2.We will fist check customer’s goods and goods size, then we will recommend suitable wrapping machine to 100% suitable.

3.We will recommend and offer machine according to customer’s use and purchase budget.

In-sale service:

1.We will supply each manufacturing step photo for customer checking on time.

2.We will prepare packing and shipment according to customer’s needing in advance.

3.Testing the machine and making video for customer’s checking.

After-sale service:

1.We will guarantee the machine quality for 1 year.

2.We provide free training and answer customer's question on technology in time.

Our Customer

Welcome to Shanghai. Welcome to visit our company.

Certificate

FAQ

1. What about your baling machine quality?

Our factory has more than 10 years experience in mechanical processing; all our machines already get ISO9001, SGS certificate, CE certificate; already exported into many countries and areas; already got customer’s good reputation.

2. What about your baling machine price?

Anytime we will make quality as factory life, no matter price is good or not for us. Quality is first, on the top quality basis, Sure you will get reasonable and satisfied price!

3. How can you ensure the machine’s quality after we put the order?

Before the delivery, we will send you machine’s pictures and videos, or you can come to us to have the quality checking by yourself, or by the third party inspection organization contacted by your side.

4.What about your installation service and sales service for baling machine?

1>Guarantee is one year, we will supply spare parts or send engineers to your side if you need, we will give you service anytime, 24 hours, 7days.

2>We already prepare technical manual and operation video to show our customers, then it will be easy to install and use the machine.

3>It is free to train your worker in our factory or in your side or by video.

Contact Us

Sales Manager : Jack Meng

WhatsApp and Mobile:0086-13621903276

Skype:ccsser

Descriptions And Features:

1. The machine is a auto-liquid filling devise which is composed of PLC, human-computer interface, optoelectronic sensor and air-powered. The machine adopts time control theory, switch time of the solenoid valve control the filling dose precisely. The machine is unique in simple operating, stable performance, accuracy measuring, no dripping or leaking and convenient in changing model. It is widely used in pharmaceuticals, food industry, Cosmetics, agricultural chemical, chemical industry and etc.

2. The machine adopt linear filling. The bottle conveyed through conveyer belt. When the bottle arrives at the blocking bar, the bottleneck is rightly below the filling pipe. After the optoelectronic sensor detecting the last bottle and delay a while, the filling cylinder opens and the liquid filled into bottles. Blocking bar at the outlet draws back after bottles filled. The bottles filled deliver by the conveyer belt. the filling done. The blocking bar at the inlet transport the next set of bottles.

3. (1)The filling machine stops automatically and alarm when lack empty bottle or no bottle enters and optoelectronic sensor at the inlet doesn’t detect signal.

(2)When the following line blocked, the filled bottle can’t deliver, the optoelectronic sensor at the outlet detects the signal and stop filling automatically.

Line liquid filling machine RG-8

filling range | 50~1000ml |

filling speed | 20~100 bottles/min |

filling precision | ≤±1% |

voltage | 220V |

mains frequency | 50Hz |

power | 2.5kw |

Working barometric pressure | 0.4~0.6MPa |

Air consumption | 0.4 |

weight | 470kg |

size | 2060×780×2100mm |