Высококачественная гидравлическая машина для резки и перфорации ERMAK комбинированная обработки железа с

- Категория: Электро-гидравлический гибочный пресс >>>

- Поставщик: Ermak,CNC,Machine,(Nantong),Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 7069.79 $* | 7422.56 $* |

| Aug-17-2025 | 7009.69 $* | 7359.77 $* |

| Jul-17-2025 | 5881.57 $* | 6175.96 $* |

| Jun-17-2025 | 6890.0 $* | 7235.81 $* |

| May-17-2025 | 5999.57 $* | 6299.20 $* |

| Apr-17-2025 | 6772.75 $* | 7111.81 $* |

| Mar-17-2025 | 6712.16 $* | 7048.52 $* |

| Feb-17-2025 | 6653.44 $* | 6986.75 $* |

| Jan-17-2025 | 6593.78 $* | 6923.46 $* |

Характеристики

ERMAK High Quality hydraulic ironworker shearing and punching machine combined CNC iron worker

EKM Iron Worker

EKM series will be your best choice to fulfill your expectations for price, efficiency and quality rates.

ADVANTAGES

- EKM series IronWorker is renewed as a result of Ermaksan engineering studies while it is designed with 3D CAD software and manufactured with accurate CNC machinery.

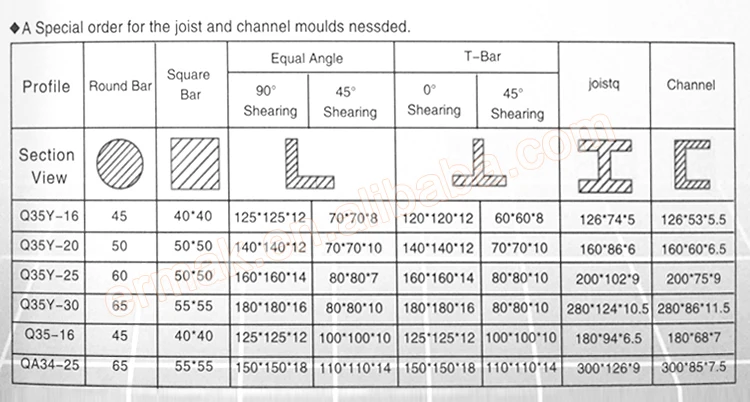

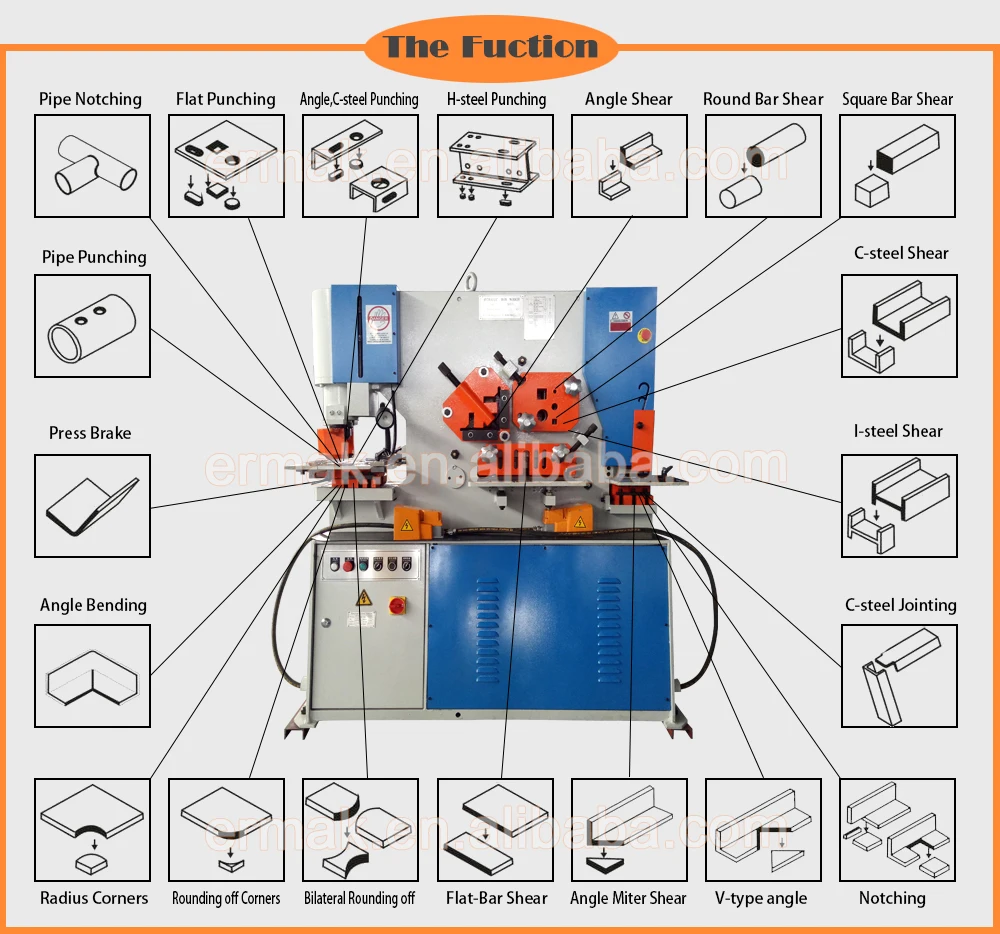

- EKM series contain stations for punching, profile cutting, square and round bar profile cutting, flat sheet cutting and corner notching. Each work station provides accuracy and ease of use while ensuring safety with special covers.

- EKM series IronWorker is contributing your business in economic powers while increasing your production efficiency with its unique cutting technology.

PRODUCT DESCRIPTION

- Double cylinders hydraulic punch & shear machine

- Five independent stations for punch, shear, notcher, section cut

- Large punch table with multi-purpose bolster

- Removable table block for overhang channel / joist flange punching applications

- Universal die bolster, easy change punch holder fitted, punch adapters supplied.

- Angle, round & square solid monoblock crop station.

- Rear notching station, Low power inching and adjustable stroke at punch station.

- Centralised pressure lubrication system.

- Electric panel with overload protaction elements and ingetrated controls.

- Safety movable foot pedal.

BRIEF INTRODUCTION

Ironworker is a combination metal machine tools, which can be for cutting ,punching, shearing, bending, and other functions, easy operation, low energy consumption, maintenance, and low cost, is the perferred device of modern manufacturing (such as: metallurgy, bridges, telecommunications, power, military and other industries) metal processing.

Whole structure of the hydraulic iron worker:

- Q35Y Series Hydraulic Iron Worker, Totally European design,The machine are strong and easy to use machines which are able to can cut and punch all kinds of materials such as plate, square bar, angle, round bar, channel and so on.

- SanxinIndustrial hydraulic ironworkers have been designed and built to the highest quality standards in the industry. This profitable machine will serve any grueling fabrication shop for decades to come

- The machine by the European Union CE certification and ISO quality system certification

Hydraulic system:

- Adopt integrated hydraulic control system, more reliable and easy for maintenance.Hydraulic system is from

- All seals in cylinder is PARKER from USA,the most famous brand,good quality and high performance

- Being able to work under rated load continuously,stable working and high precision.

Machine Blade:

- The rectangular monoblock blades featuring long life with 4 cutting edges, quality high-carbon high-chrome blades SKD11 quality.

- We provide you the die cutting mould, round bar punching , and angle cutting . The Channel cutting mould and I type mould we can provide you one .

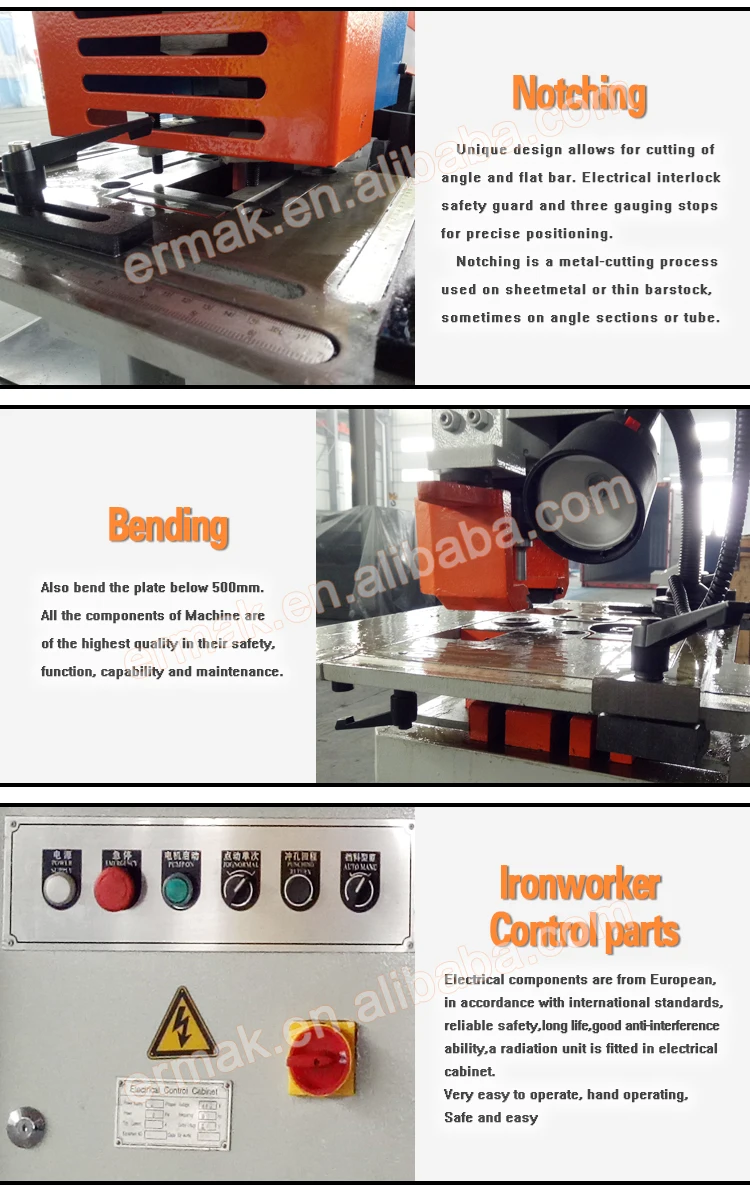

Electrical system and the safety interlock:

- Electrical components are from European,in accordance with international standards,reliable safety,long life,good anti-interference ability,a radiation unit is fitted in electrical cabinet.

- Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

- Emergency stops on machine and foot switch for safety,Foot pedal conforming to CE regulation.

PARAMETER

| Model | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-50 | ||

| Processing Capacity (KN) | 600 | 900 | 1200 | 1600 | 2000 | 2500 | ||

| Material Tensile Strength (Mpa) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ||

| Flat Shearing | Max. Shearing Capacity | 16×250 | 20×330 | 25×330 | 30×355 | 35×400 | 40×450 | |

| (thickness* width (mm) | 8×400 | 10×480 | 16×600 | 20×600 | 25×700 | 30×750 | ||

| Bar Shearing | Square Bar(mm) | 40 | 45 | 50 | 55 | 60 | 65 | |

| Round Bar (mm) | 45 | 50 | 60 | 65 | 70 | 80 | ||

| C-channel (mm) | 126 | 160 | 200 | 280 | 300 | 320 | ||

| I-beam (mm) | 126 | 160 | 200 | 280 | 300 | 320 | ||

| Angle shearing | 90° shearing (mm) | 120×12 | 140×12 | 160×14 | 180×16 | 200X18 | 200×20 | |

| 45° shearing (mm) | 70x8 | 70x10 | 80x7 | 80x10 | 80x10 | 80x10 | ||

| Hole Punching | Max. Punching Capacity (diameter* thickness) (mm) | Φ25*16 | Φ30*20 | Φ35*25 | Φ38*26 | Φ40*35 | Φ40*40 | |

| Motor (KW) | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | ||

| Dimension(mm) | Length | 1650 | 1950 | 2350 | 2680 | 2800 | 3200 | |

| Width | 800 | 900 | 980 | 1060 | 1260 | 1440 | ||

| Height | 1780 | 1930 | 2100 | 2380 | 2420 | 2450 | ||

| Weight | 1800 | 2600 | 4400 | 6600 | 7500 | 10800 | ||

| Model | Q35YL-50 | Q35YL-60 | Q35YL-90 | Q35YL-120 | Q35YL-160 | Q35YL-200 |

| pressure | 50 | 60 | 90 | 120 | 160 | 200 |

| Max thickness(mm) | 12 | 16 | 20 | 25 | 30 | 40 |

| Sheet strength(N/mm2) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 |

| Slider travel(mm) | 7 | 7 | 8 | 8 | 8 | 8 |

| Punching angle(°) | 300*12 | 16*250 | 20*330 | 25*330 | 30*335 | 35*400 |

| 8*400 | 10*480 | 16*600 | 20*600 | 25*700 | ||

| One shearing size | 35 | 80 | 80 | 80 | 80 | 80 |

| Travel(times/min) | 10-18 | 9-25 | 12-28 | 12-28 | 12-28 | 10 |

| Throat depth(mm) | 115 | 300 | 355 | 400 | 600 | 600 |

| Punching thickness(mm) | 12 | 16 | 20 | 25 | 28 | 35 |

| Max punching diameter(mm) | 25 | 25 | 30 | 35 | 28 | 40 |

| Main motor | 4 | 5.5 | 7.5 | 11 | 11/15 | 15/18.5 |

| Machine size(mm) | 950*550*1800 | 1640*730*1770 | 1860*800*1900 | 2355*960*2090 | 2680*1040*2300 | 2970*1240*2350 |

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.

|  |